What are the different kinds of non stick coating for baking trays pans?

As a leading manufacturer of baking tray pans for commercial and industrial use, our company understands that choosing the right baking tray with the right non-stick coating can make all the difference in creating perfect baked goods and baking budgets of years to come. However, with so many different types of non-stick coatings available on the market, it can be overwhelming for customers to make an informed decision. In this article, we aim to demystify the various non-stick coatings available for baking trays, and help our customers understand the differences between them so they can make an informed choice when selecting the perfect non-stick baking tray for their needs.

Alongside discussing the various non-stick coatings available for baking trays, we will also provide guidance on how to handle and care for your non-stick baking tray in this article. Additionally, we will address some frequently asked questions and concerns that customers encountered when using non-stick baking trays.

1. What are the commonly used non stick coatings ?

There are four kinds of non-stick coatings for baking pans that we use, domestic Teflon, imported Teflon, imported powder coating, and imported high-sugar silicone coating. The first two are also commonly referred to as liquid-based coatings. The fourth is the oily coatings that people often say. Powder coating is the best quality and most durable but can be very expensive. For the same specification of a baking tray, the powder Teflon coated one is 2.5 to 5 times expensive that of other coated bakeware, depending on the thickness of the powder coating, the materials used and several spraying processes required during sample production.

Domestic Teflon Coating

The first type is domestic Teflon, we rarely use. It is generally used for baking trays with paper liners, which are easy to clean. The number of non-stick times is about 800 times, which is relatively small, but fortunately, the price is the cheapest. It is more cost-effective for clients who has limited budget and recipes requiring paper liner in the baking process.

Imported Teflon Coating

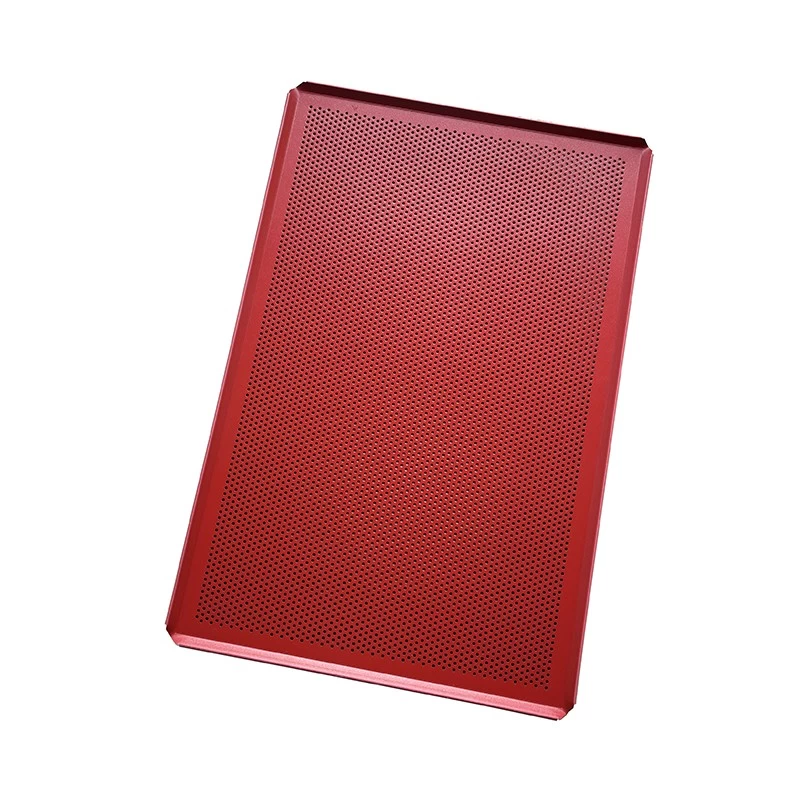

The second type is Teflon coating imported from the United States. It is the best selling non-stick coating material for the bakeware and we use the most. It also contains two kinds, American DuPont double-layer Teflon and American DuPont three-layer Teflon. Double-layer Teflon is suitable for bread with low sugar content, and the non-stick times are about 1200-1500 times, while three-layer Teflon can reach about 1500-2000 times. The two layers of Teflon are generally black, because black absorbs heat, has better baking effect and shorter baking time than brown paint, so there are more black non stick coated baking pans in the market. Three layers of Teflon are generally in golden and champagne color. In the case of a large number of orders, we can color according to the customer's color palette.

Notes: Liquid-based Teflon coating does not require oil injection, even a small amount of oil injection is not required. However, some customers may encounter a small amount of adhesion for the first time baking, which is normal. It is recommended that spraying a small amount of oil when using the liquid-based Teflon baking pan for the first time, and do not need to do any oil spray maintenance after the first baking. The purpose is to promote the stability of the non-stick performance of the new bakeware, so that no oil spray is required in the future.

Powder Teflon Coating

The third type, is American DuPont powder Teflon coating. It is suitable for baking those food products with pure flour and no oil, and the non-stick times can reach about 3000 times. For example, the KFC specifies that the hamburger pan with American DuPont powder Teflon non-stick coating required. For another example, the one-piece stretched toast box we export to Africa is required to last for 3-5 years, so our clients can only choose powder Teflon coating which can meet the demands. The disadvantage of imported powder Teflon coating is the high price.

It is worth noting that powder Teflon coating is generally used on aluminized steel material. Because the aluminum alloy itself has a limited service life and the powder Teflon coating has a longer service life, it is not necessary to use powder Teflon coating on aluminum alloy baking pans. Aluminum alloy and powder coating are no match. In order to give full play to the non-stick times of the powdered Teflon coating, a more durable aluminized steel material is applied to make the baking pan.

Silicone Coating

The fourth type, the silicone non-stick coating we use is imported from Japan, suitable for high-sugar cakes, and the non-stick times are about 800-1000 times. Silicone non-stick baking pan makes the cake easy to release and has a complete shape, but the price is higher than Teflon coated ones. In terms of market demand, silicone non-stick baking pans are much less than Teflon non-stick baking pans, probably because cake batter does not need to be fermented like bread dough, and does not occupy a large number of baking pans in the food production process.

Why do we say that the non-stick times of Silicone non-stick bakeware are in the range of 800-1000 times? Because the specific use is closely related to the customer's food formula. The recipe we tested is the best ratio of eggs to flour 7:3, the cake produced under this ratio has the best taste.

Silicone bakeware requires a small amount of oil spray, not excessive oil spray, and must be cleaned regularly. Otherwise, a hardened grease layer will be formed after long-term use, and the cake will directly contact the grease layer without touching the non-stick coating. The grease layer will cause food to stick, thus forming a misunderstanding of poor non-stick performance.

2. What are the differences of these non stick coating in non-stick times, baking temperature, advantages and disadvantages ?

|

Coating |

Non-stick times |

Baking temperature |

Advantages |

Disadvantages |

|

Domestic Teflon |

800 times or so |

220℃-260℃ |

Low price |

Less times of non-sticking |

|

American DuPont Teflon |

Double-layer 1200-1500 times or so Three-layer 1500-2000 times or so |

220℃-260℃ |

More durable |

Higher price |

|

American DuPont Powder Teflon |

3000 times or so |

220℃-260℃ |

The most durable |

The most expensive |

|

Japanese Silicone coating |

800-1000 times or so |

220℃-260℃ |

cakes are easy to demould |

High price |

Generally speaking, the baking pan is used to bake bread and cakes at a temperature of 220°C-260°C. We emphasize that the number of non-stick times is that how many times it can be recycled under a baking temperature not more than 260°C. Generally, the oven will have a temperature difference, set at 220°C, and the oven may reach 240°C-260°C.

260°C-280°C is at a zero point. In this range, the coating is easy to be carbonized and damaged, resulting in the failure of the coating to achieve the expected life.

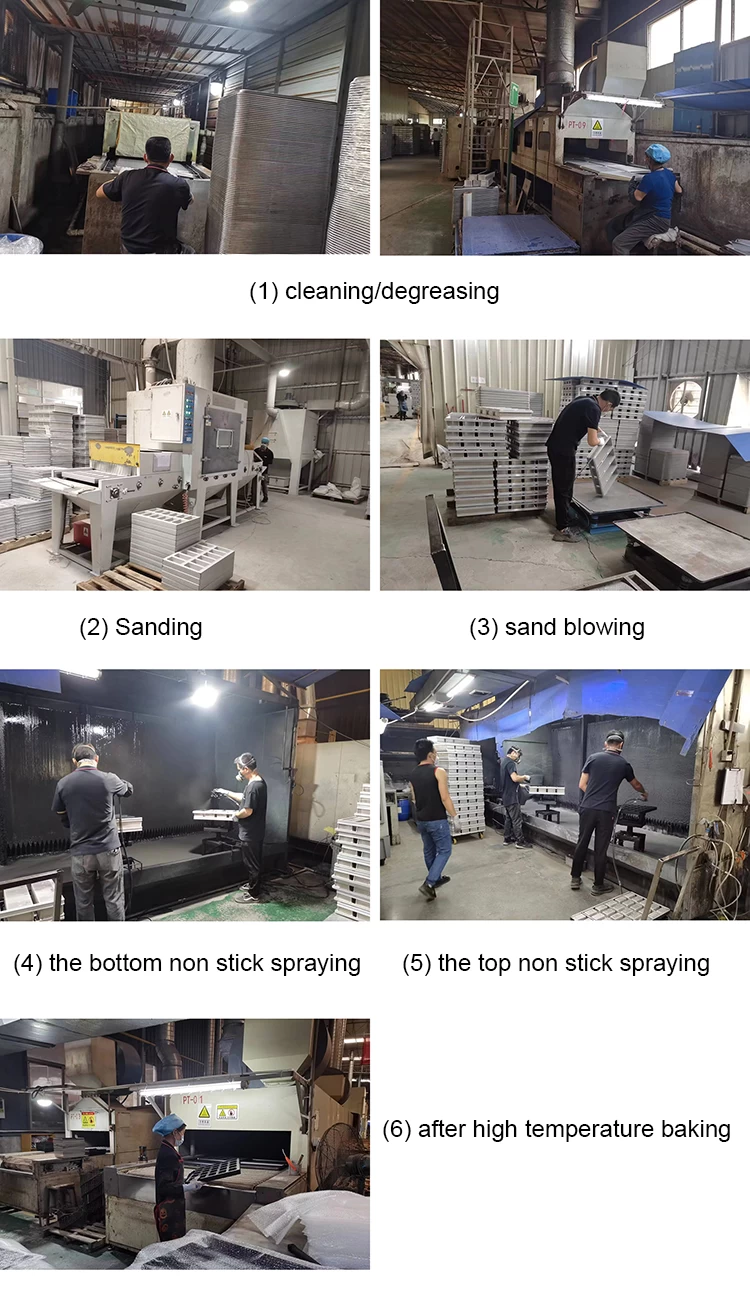

3. What is the difference of non stick coating spraying procedures ?

The spraying process of non-stick coating must go through these procedures:

(1)cleaning/high temperature degreasing

(2)Sanding

(3)sand blowing

(4)low temperature baking

(5)high temperature baking

(6)finished product non-stick coating thickness inspection

(7)packing

Non stick coating baking time and temperature (baking pan production):

Liquid-based Teflon coating :

The first layer of low-temperature furnace: 150 ° C, 10 minutes

The second layer of high-temperature furnace: 380 ° C, 15 minutes

Powder Teflon:

The first layer Low temperature furnace: 150°C, 10 minutes

The second layer of high-temperature furnace: 380 ° C, 20 minutes

Oily coating silicone:

The first layer Low temperature furnace: 130°C, 10 minutes

The second layer of high-temperature furnace: 280 ° C, 20 minutes

4. What are the notes for using non-stick baking pan?

(1) The newly purchased non-stick baking pan may be slightly deformed within the first 90 days of use. This is a normal phenomenon of metal thermal expansion and contraction, which is not a product quality problem. It will return to normal after a period of use.

(2) General Teflon non-stick baking pans are suitable for baking bread. Silicone nonstick bakeware is suitable for baking high-sugar foods. Moreover, because cakes are high-sugar foods, the non stick bakeware must be oiled each time they are used (ghee, pan oil or salad oil) to improve the non-stick effect and improve the perfect out coming of food (currently for high-sugar foods, domestic and foreign There is no paint that is easy to release without oiling).

(3) Our baking pans are all imported international brands, using advanced equipment and manufacturing technology, with extremely high temperature resistance, wear resistance and non-stick. All products have been strictly tested, and the number of uses can meet the specified requirements.

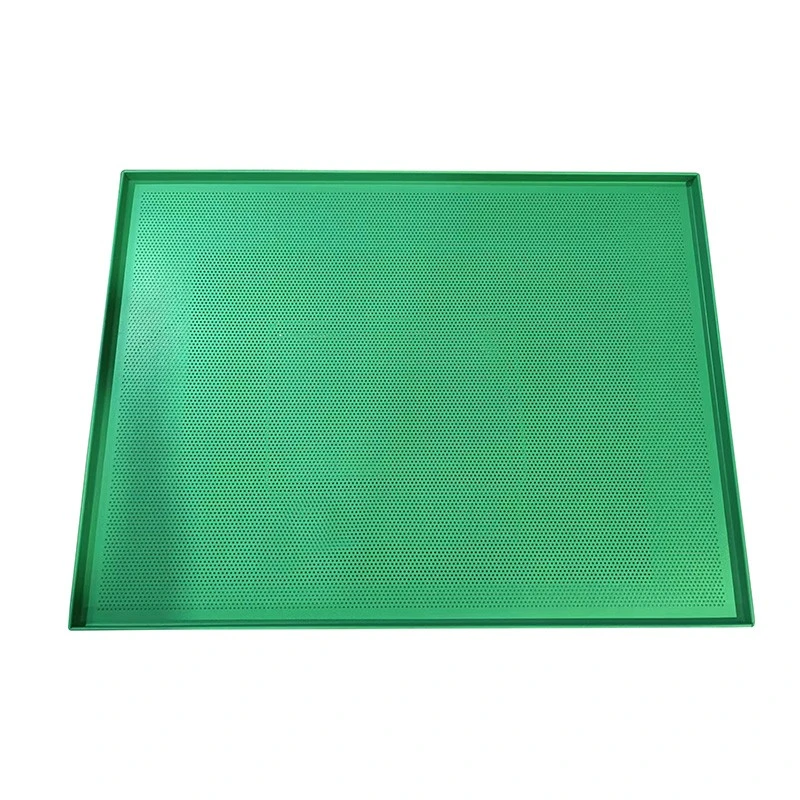

non stick perforated French bread baguette pan

5. How many times can the non stick baking pans be used ?

The number of uses of non-stick baking pans is closely related to the use environment and daily operations, especially the baking temperature, baking time, and food formula of each baking. The temperature setting during baking is generally lower than 220°C, and the non-stick times of the baking pan varies according to the baking time each time. For American Dupon 3-layer Teflon non stick coated baking pans, if it is baked for 15 minutes at a time, and the non-stick times of baking tray is generally not less than 1500/2000 times. If it is baked for 30 minutes or longer at a time, the non stick baking pan service life will be relatively reduced. In addition, the life of the non-stick baking pan is also related to the material composition of the baked food. For foods such as Danish dough, it can reach 1500/2000 times under normal baking, but for sweet bread cakes with high sugar content etc., the service life will be relatively reduced. Customers can follow this instruction to use the product reasonably and understand the factors involved in the non-stick times of the non-stick bakeware.

6. How to maintain a non-stick baking pan ?

(1) Before using the newly purchased non-stick baking pan, you need to clean the inside first, dry it with warm fire or wipe it with a soft cloth before using it;

(2) Do not use sharp metal objects, scouring pads, and chemical cleaners to wipe;

(3) After each baking, please use a soft cloth or a soft plastic scraper to remove the residue left in the baking pan;

(4) After each baking, please do not soak in acidic cleaning liquid for a long time;

(5) After using the non-stick baking pan for a period of time, it is best to add a small amount of neutral detergent to warm water to remove the residue, and clean it thoroughly with a soft cloth;

(6) Do not leave baked foods or unbaked dough/pastry etc. in the baking tray, because the corrosion products formed by the moisture, sugar and starch accumulated in the food will corrode and oxidize the metal material at the bottom of the non-stick coating;

(7) Take it up and down in the vertical direction when using it, and try to avoid collisions and frictions caused by improper operation, which will cause wear and scratches on the non-stick coating;

(8) Handle with care when storing and stacking, keep the baking pan dry, and do not storage in wet places;

(9) When the non-stick coating is operated under the condition of great temperature difference between high and low temperature for a long time, tiny cracks will be generated, causing residual substances to erode the non-stick coating, and the non-stick coating will eventually lose its non-stickiness. To avoid this from happening, we recommend:

a. The baking temperature is lower than 220°C, which can prolong the service life;

b. Avoid uneven heating of the baking pan;

c. Can not burn empty;

d. Do not use high-temperature steam to cook or clean the non-stick baking pan for a long time, otherwise it will easily cause the non-stick layer to peel and fall off.