What are the main factors affecting gluten formation

As one of the most common and basic materials in daily baking, flour is not as simple as we seem, which makes bakers very difficult to control their performance.

This time, we will dig deeper into the problems that will arise in the practical application of flour.

What are the main factors affecting gluten formation?

What is the content of flour?

What effect can these contents play in the formulation?

How to enhance the effect of flour?

Part One: the main factors affecting the gluten formation

This is the key point that I want to share with you today, and also the starting point of collecting this information.

When we make bread and pastries in our daily life, it is impossible to have the same requirement for dough gluten. So how to adjust the gluten, and even how to produce gluten, we have not said before.

So what is the reason that affects the formation of gluten, and what materials can enhance or weaken the strength of gluten?

What are the reasons for the formation of gluten?

1. Types of flour used

2. The amount of added water

3. Times of mixing and kneading

4. The Mixing materials in Flour

5. Time of mixing other materials

How to reduce gluten strength?

1. Adding Alcohol: When liqueur or wine is mixed in flour, alcohol dissolves gliadin and reduces viscosity.

2. Adding acid: When mixed with lemon or vinegar in flour, acidity will dissolve wheat hub protein, thus forming gluten with weak viscosity.

3. Adding sugar: When mixed with sugar and flour and mixed with water, sugar absorbs water first to weaken the formation of gluten.

4. Adding grease: When oil and flour are mixed and mixed with water, the flour particles will be coated by oil, which will affect the water absorption and weaken the formation of gluten.

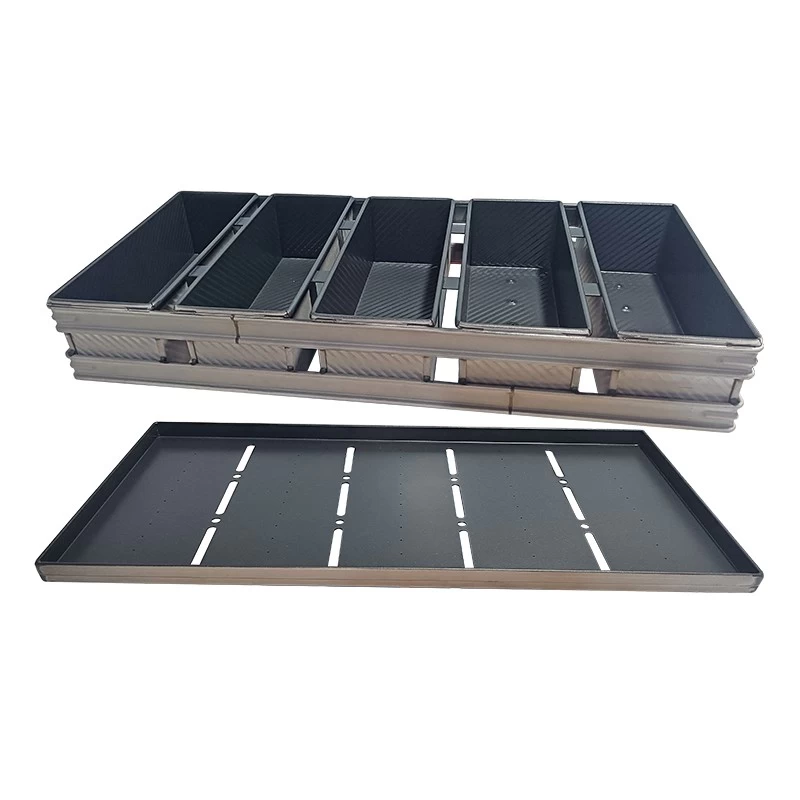

Bakeware Recommendation: Bread proffing basket for dough fermentation

From China banneton basket factory

How to strengthen gluten strength?

Adding salt: When salt is added to flour and water is added, the viscosity and elasticity will increase. So salt is added to bread.

What is the true face of gluten?

We can mix the flour and water into the dough. Put it into water. Finally, there will be elastic lumps left behind. It's like gluten.

Part Two: Gelatinization of starch

To understand flour, we must first understand its ingredients. Flour mainly contains protein and starch. The existence of these two ingredients is the reason why it can produce various effects.

About 70% of the flour is starch. When granular starch is heated to absorb water, the particles become larger and form a pasty viscous substance, which is called "gelatinization". The expansion of puff batter is formed by skillfully utilizing this gelatinization effect:

Oil in butter can inhibit the formation of gluten, so melting flour in butter at 87 C can not only inhibit the production of gluten, but also make starch form a viscous gelatinization effect, making dough swell after baking.

However, do you know that gelatinization also has different degrees? We usually control the effect of gelatinization so as to making pastries with different taste characteristics. As for application in practice, there are roughly three types of flavor.

1. Tower cake dough: Inhibiting gelatinization

In order to make a loose taste, the gelatinization effect is kept to a minimum. Therefore, the tower cake dough will use a small amount of water, and try not to mix before heating baking.

2. Casta butter filling: Medium gelatinization

Egg yolk and sugar, a small amount of flour mixed, poured into the milk heated, will form a thick and appropriate butter filling. After cooling, the viscosity will increase and the mixing will be smooth.

3. Puff Paste: Full Gelatinization

When heated with low-gluten flour in a liquid above 85 C, the desired viscosity will be formed. By adding eggs, a hollow puff cake skin can be baked in the center.

Part Three: Gluten Formation

Flour contains two proteins, gliadin and glutenin, which can be combined to form "gluten" by mixing with water.

The properties of gluten are mainly viscous and elastic. For example, when pie dough is rolled with a rolling pin, the film will not break, that is, the function of gluten. When making sponge cake batter, the pasting stickiness of the flour mentioned above has the effect of supporting gluten tissue and avoiding its collapse, and the two complement each other.

Part Four: How to adjust the effect of gluten to meet different requirements

1. Non-kneading dough

There is no need for elasticity in the crisp tasty pagoda dough. Only a little gluten is needed when rolling, so cut and mix to avoid kneading.

2. Add boiling liquid

Puff batter is made by mixing low gluten flour into boiling butter liquid and heating it at above 85°C until it is viscous.

3. Don't over mix dough

Sponge cake batter after heating low-gluten flour, in order to avoid excessive elasticity of gluten, do not mix with big movements.

4. Put in fermented dough

High-gluten flour is used in fermented pastries such as doughnuts, and the strong elasticity is used to keep the gas in the dough during fermentation.

5. mixing-use two kinds of flour in basic dough

The basic blending of pastry dough is low gluten flour and high gluten flour. Dough hardness can be made and layers of butter can also be distinct.

Bakeware Recomendation: Mesh Stainless Steel filter Strainer with Silicone Handle

From Tsingbuy China flour strainer manufcaturer

6. Lay aside static for a while after rolling

After kneading or rolling, dough is not rolled directly because of its strong elasticity. In order to weaken the excessive elasticity, it needs to be stationary.

Tips:

Static can relax the gluten structure under the strong rolling state, and it will become easy to press.

When making soft batter, we must pay attention to mixing method:

When making the batter of egg-splitting sponge cake, it is very important to mix it by cutting and mixing after adding flour. If a small area is carefully mixed several times to produce gloss, the batter will become soft and smaller, and hardened when baked.

Bakeware Recomendation: Amazon Hot Sale Stainless Steel Dough Pastry Blender TSPB

From Tsingbuy China pastry blender manufacturer