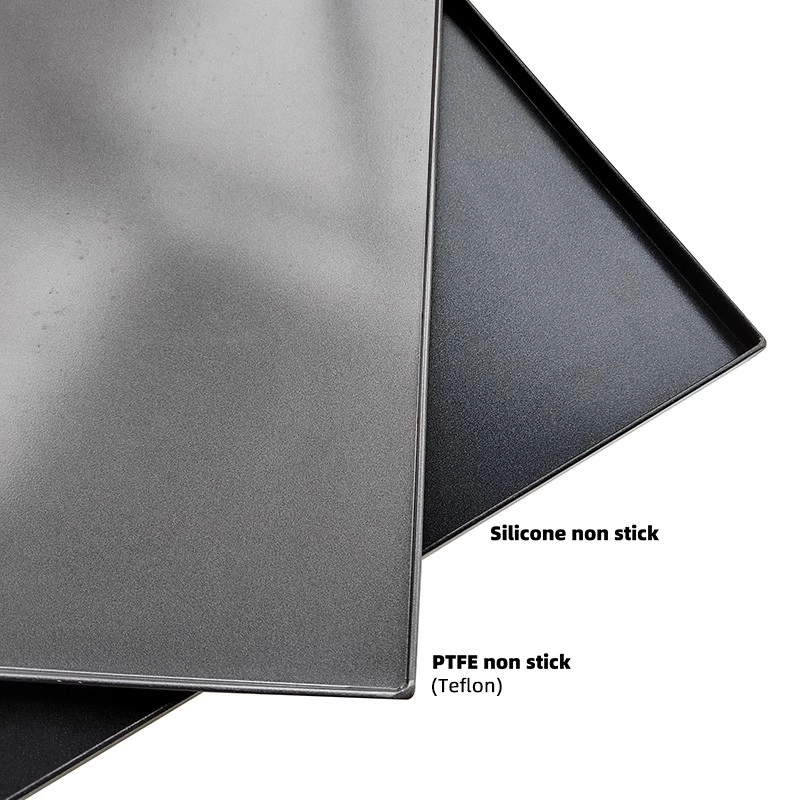

Teflon Coating Vs Silicone Glaze, which one is Better for Commercial Baking Pans?

In the following sections, we’ll explore the unique properties and applications of Teflon coating and silicone glaze, two popular materials used in commercial cookware. We’ll compare their non-stick performance, heat resistance, durability, and safety, helping you understand how each material functions in demanding kitchen environments. Additionally, we'll examine their suitability for specific commercial uses, from frying and sautéing with Teflon-coated pans to baking with silicone-glazed molds. By the end, you’ll have a clear understanding of which option is best suited for your professional baking needs.

Main Contents

What are the difference betweem Teflon coating and silicone glaze?

How to care and maintain Teflon coated bakeware?

How to care and maintain silicone glazed bakeware?

Which one is better for commercial baking pans?

What is Teflon coating?

Teflon coating is a non-stick surface made from polytetrafluoroethylene (PTFE), a synthetic polymer known for its low friction and heat resistance. It’s commonly applied to cookware, such as frying pans and baking trays, to prevent food from sticking during cooking and make cleaning easier. Teflon’s smooth, non-porous surface allows for the use of less oil or butter, promoting healthier cooking. While Teflon is highly durable, it can degrade at temperatures above 500℉ (260℃) and is prone to scratching if metal utensils are used. Its convenience has made it popular in both household and commercial kitchens.

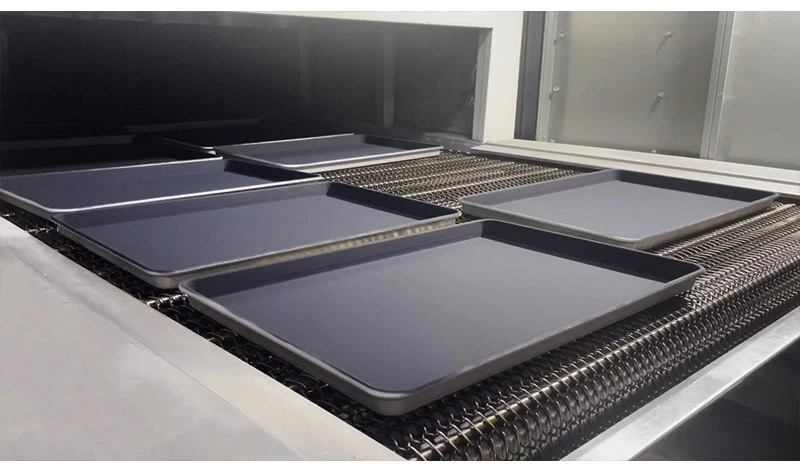

Tsingbuy is a leading baking tray factory in China since 2006. The commercial bakeware series covers sheet pans,

baguete pans, loaf pans, muffin pans and bakery trolley etc for commercial bakery and automatic production system.

What is silicone glaze?

Silicone glaze is a food-safe coating made from silicone, typically applied to bakeware and cooking molds to provide non-stick properties. It forms a flexible, rubber-like surface that helps prevent food from adhering, making it easier to release baked goods like cakes, breads, and pastries. Unlike traditional non-stick coatings, silicone glaze is highly resistant to heat (up to 450℉ or 232℃) and remains stable at both high and low temperatures. It’s durable, dishwasher-safe, and doesn’t scratch easily, making it a practical option for commercial kitchens. Additionally, silicone glaze is considered safe for food contact and free of harmful chemicals.

What are the differences betweem Teflon coating and silicone glaze?

Material Composition:

Teflon Coating: Made from polytetrafluoroethylene (PTFE), a synthetic polymer known for its non-stick properties and low friction.

Silicone Glaze: Silicone-based, typically composed of silicon atoms and oxygen atoms, often with methyl or phenyl groups attached, a flexible, rubber-like material often used in bakeware for its non-stick and heat-resistant qualities.

Both coatings are chosen for their non-stick properties, but Teflon tends to be used more in cookware and baking trays due to its extremely low coefficient of friction and excellent non-stick performance under high heat, while silicone glazes are often used in baking molds for their flexibility and non-reactive nature.

Durability:

Silicone glaze typically lasts for about 250–300 baking cycles before it begins to wear down, exposing the metal underneath and requiring recoating. This means that in high-use environments, silicone glaze may need replacement after roughly a month of regular use. In contrast, Teflon coatings can endure over 3,000 cycles when used properly, which equates to about a year of baking before recoating is necessary. This extended lifespan reduces the need for frequent recoating, helping to lower costs and minimize oven downtime.

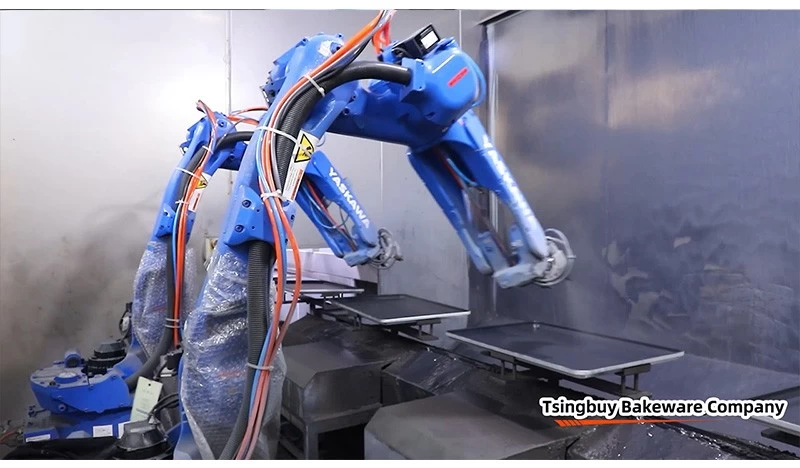

Although both coatings can wear out if not properly maintained (especially if sharp utensils are used), silicone glaze is more prone to flaking, which can result in burnt particles ending up in baked goods more frequently than with Teflon. Teflon coatings, especially durable 2-coat or 3-coat systems, further minimize the risk of flaking, making them a more reliable option for long-term use in commercial kitchens. Tsingbuy baking pans manufactruer in china provides professional ODM&OEM non stick bakeware for commercial bakery and automatic production system since 2006, and has loyal customers all over the earth with high quality product and professional service.

Non-Stick Properties:

While both silicone glaze and Teflon coatings are known for their effective non-stick properties, they function quite differently when it comes to usage. Silicone glazes often necessitate the additional application of oil or grease to ensure that baked goods can easily slide in and out of trays without leaving any residue behind. This extra step can be inconvenient for bakers looking for efficiency and convenience. On the other hand, fluoropolymer/Teflon coatings are designed to eliminate the need for added oil. Their unique, ingrained non-stick characteristics significantly reduce friction, allowing a variety of baked items—such as loaves of bread, cakes, pies, and more—to effortlessly slide out of trays. This feature not only enhances the baking experience but also simplifies cleanup, making Teflon-coated cookware a preferred choice for many professional and home bakers alike.

Heat Resistance:

Teflon: Can withstand moderate to high heat but degrades above 500℉ (260℃).

Silicone: More heat-resistant, withstanding temperatures up to 450℉ (232℃) without degrading.

Ease of Recoating

Before trays can be recoated with a new layer, it is essential to completely remove the old coating and thoroughly clean the surface of the underlying pan or tray. This process typically takes place in an abrasive blasting chamber, where specialized equipment is used to strip away the old material. However, unlike Teflon, silicone particles tend to mix with the abrasives during this blasting process, leading to potential contamination. This contamination poses a significant issue, as it renders the abrasives unsuitable for future use; silicone particles may remain mixed in with the abrasives and can transfer onto the surfaces of other metal parts.

As a result, if the contaminated abrasives are employed again, it could lead to a situation where other pans in the current batch, or even in subsequent batches, become tainted with unwanted silicone particles. This contamination complicates the cleaning and deburring processes, reducing their overall effectiveness and efficiency. In contrast, Teflon coating offers a more resource-efficient solution, as the abrasives used in the blasting process can be reused multiple times without the risk of cross-contamination, ultimately saving both time and materials in the recoating operation.

How to care and maintain Teflon coated bakeware?

Caring for and maintaining Teflon-coated bakeware is essential to ensure its longevity and performance. Here are some tips for proper care:

1. Avoid Metal Utensils: Use wooden, silicone, or plastic utensils to prevent scratching the Teflon surface.

2. Gentle Cleaning: Wash by hand using warm soapy water and a soft sponge or cloth. Avoid abrasive cleaners or scouring pads that can damage the coating.

3. Avoid High Heat: Do not use Teflon bakeware at extremely high temperatures. Stick to the manufacturer's recommended temperature limits, typically around 260°C (500°F).

4. Preheat Carefully: If preheating your oven, place the Teflon bakeware in after the oven has reached the desired temperature to prevent warping.

5. Store Properly: Stack bakeware with protective padding (like paper towels) in between to avoid scratches when storing.

6. Avoid Cooking Sprays: While Teflon is non-stick, using non-stick cooking sprays can leave a residue. If you must use them, ensure to clean the surface well afterward.

7. Regular Inspection: Periodically check the coating for any signs of wear or damage. If you notice significant scratching or peeling, it may be time to replace the bakeware.

8. Avoid Cooking on Stovetops: Teflon bakeware is designed for oven use only. Using it on stovetops can lead to damage.

By following these care and maintenance tips, you can help extend the life of your Teflon-coated bakeware and keep it performing well.

How to care and maintain silicone glazed bakeware?

Caring for and maintaining silicone-glazed bakeware is relatively straightforward, thanks to its durable and flexible nature. Here are some tips for proper care:

1. Cleaning: Hand wash with warm, soapy water and a soft sponge or cloth to clean the bakeware. Avoid abrasive pads or harsh chemicals that can scratch the silicone surface. Most silicone bakeware is dishwasher safe, but it’s best to strictly follow the manufacturer’s instructions.

2. Avoid Sharp Utensils: Use wooden, silicone, or plastic utensils to prevent cutting or damaging the silicone surface.

3. Preheating: Avoid placing the metal bakeware in a cold oven. Preheat the oven before inserting the bakeware to prevent warping.

4. Temperature Control: Most silicone glazes can withstand high temperatures, but always check the manufacturer's recommendations. Avoid exposing the bakeware to extreme temperature changes, such as moving it from the freezer to a hot oven.

5. Preventing Stains and Odors: Clean the bakeware promptly after use to prevent staining or retaining odors. For stubborn stains, soak the bakeware in a solution of baking soda and water.

6. Storing: Store metal bakeware with silicone glaze flat, if possible, to prevent bending or warping. Avoid stacking heavy items on top of it.

7. Greasing: While silicone is typically non-stick, greasing the bakeware lightly with oil or butter can improve food release for some recipes.

8. Avoiding Punctures: Take care to avoid puncturing or cutting the silicone glaze, as this can compromise its non-stick properties.

9. Inspect Regularly: Regularly check for any signs of wear, such as tears or changes in texture. If you notice significant damage, consider replacing the bakeware.

By following these care and maintenance tips, you can help ensure that your silicone-glazed bakeware remains in excellent condition and continues to perform well over time.

Which one is better for commercial baking pans?

Teflon Coating is often preferred for commercial baking pans due to its superior non-stick properties, which can lead to easier food release and less cleanup. It is particularly effective for items like cakes, brownies, and breads where clean removal is crucial.

Silicone Glaze may be a better option for specific applications, such as molds or trays for delicate items, due to its flexibility and heat resistance. However, it may not offer the same level of convenience as Teflon in high-volume baking situations.

Additionally, silicone glazes frequently necessitate the application of extra oil or grease to ensure that baked goods can easily slide in and out of trays without leaving any residue behind. In contrast, fluoropolymer/Teflon coatings do not require additional oil; their specially engineered non-stick properties significantly minimize friction, allowing items like loaves, cakes, pies, and more to effortlessly release from trays. This inherent functionality makes Teflon-coated cookware more convenient for bakers, as it streamlines the baking process and reduces the need for added fats.

What’s more, in commercial kitchens, where bakeware is subjected to constant use, silicone glaze may have the edge in terms of longevity and heat resistance, especially for baking applications. Teflon remains a top choice for non-stick cooking but requires maintenance. Combining both materials can optimize efficiency across various kitchen tasks.

Speak of recoating, Teflon coated trays save on resources, as the abrasives can be reused for longer. Well-knowm, before recoating trays, the old coating must be removed, and the surface underneath cleaned, usually in an abrasive blasting chamber. Unlike Teflon, silicone particles can mix with the abrasives, causing contamination. This contamination prevents the abrasives from being reused in future jobs, which can lead to silicone particles ending up on other metal parts, complicating the cleaning process. As a result, pans in the same or future batches may become contaminated if subjected to the same abrasives. Teflon coatings, on the other hand, allow for longer reuse of abrasives, making them more resource-efficient.

If you are in the market for commercial baking pan wholesale, welcome to get in touch with us at any time for more professional info and professional bakeware solutions.