What Gauge is Best for Metal Sheet Pans?

In this article, we will explore the various metal types suitable for sheet pans, including aluminum, stainless steel, and carbon steel, highlighting their unique properties. It is important to choose the ideal gauge for metal sheet pans, regarding to the metal type and baking recipes. To prolong the service life of metal sheet pans, we also have some tips.

Main Contents

Which kind of metal sheet pan is good for baking?

What gauge is best for metal sheet pans?

Tips for using metal sheet pans?

When should I replace my sheet pan?

How to get custom made sheet pans for commercial bakery baking?

What is a sheet pan?

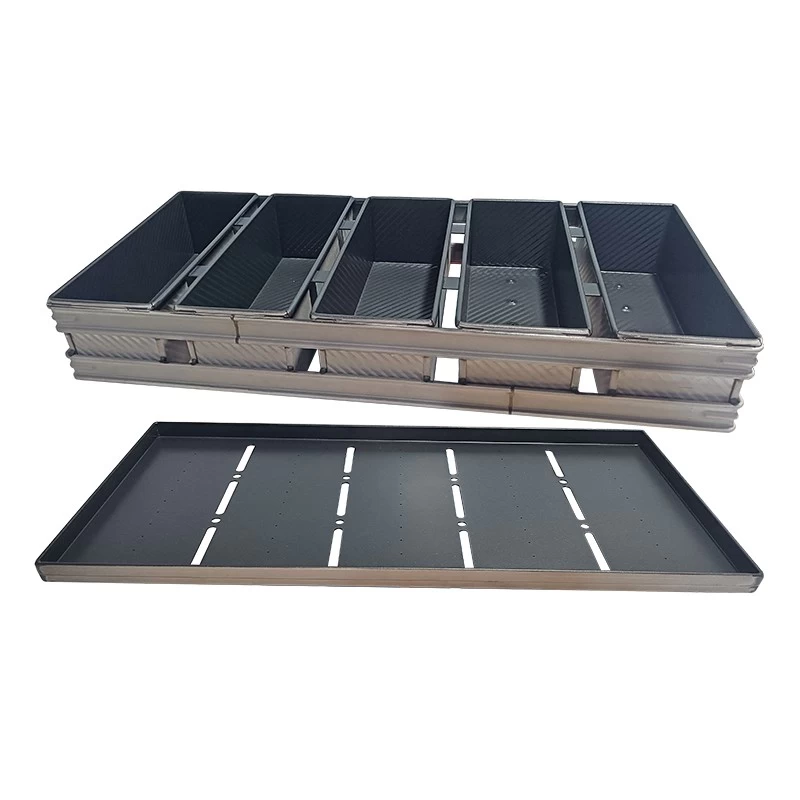

A sheet pan, also known as a baking sheet or baking tray, is a flat, rectangular metal pan used in the kitchen for baking and roasting. It is usually made of metal like aluminum, aluminized steel, stainless steel, carbon steel and has surface treatment. A sheet pan typically has low sides or rims to prevent juices or food from spilling, and it comes in various sizes. Sheet pans are are versatile and essential tools in home kitchens and commercial bakeries.

Sheet pans come in a variety of sizes. The most common sizes are 16x24 inches (40x60cm), 18x26 inches (46x66cm, full size), 18x13 inches (46x33cn, half size), 9x13 inches (23x33cm, quarter size).

Full size sheet pan is the largest standard size, often used in commercial kitchens or bakeries. It fits in large ovens and is ideal for baking large batches of food like cookies, bread, or for roasting large quantities of vegetables.

Half size sheet pan is one of the most popular sizes, found in both home and commercial kitchens. It’s versatile for everyday use, fitting in standard home ovens and used for baking smaller batches of cookies, pastries, or roasting vegetables and meats.

Quarter size sheet pan is often used in home kitchens for small-batch baking or reheating. It’s perfect for toaster ovens or for making a single tray of cookies or roasted vegetables.

The 16x24 inches (40x60 cm) sheet pan, often referred to as a European full-size sheet pan, is a popular size in European commercial kitchens and bakeries. While slightly smaller than the standard U.S. full-size pan (18x26 inches), this size is widely used in the food service industry, particularly in rack ovens and convection ovens designed for European or international baking standards. According to Tsingbuy sheet pan manufacturer in China, the 16x24 inches sheet pan is a high-demand size catering to international market.

In addition, two-thirds sheet pan(16x22 inches, 41x56cm) and eight-size sheet pan(6.5x9.5 inches, 16.5x24cm) are standard sizes too. The former one is popular in some professional kitchens. It’s slightly smaller than a full-size pan, fitting in convection ovens, and often used for more flexible baking needs.The latter one is often used for personal-sized portions or in countertop ovens. It’s perfect for small tasks like toasting nuts or baking a few cookies.

All these standard sizes allow for efficient production in commercial bakeries and kitchens, and are designed to fit both standard and convection ovens.

Which kind of metal sheet pan is good for baking?

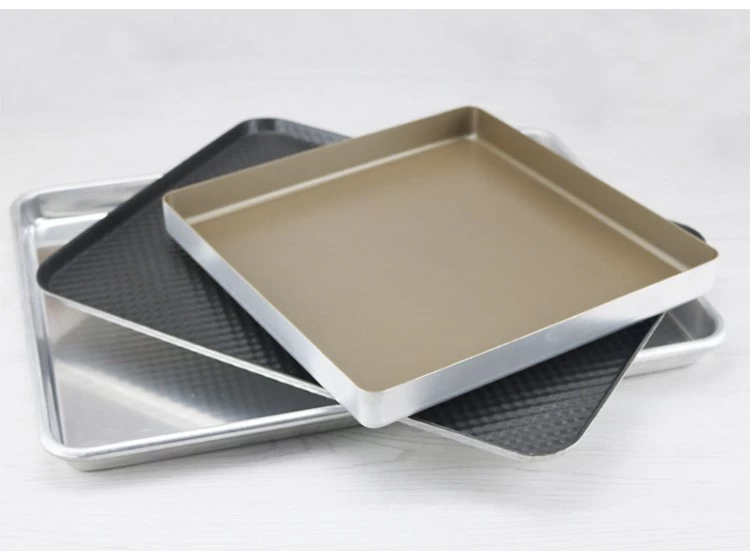

Sheet pans are made from several types of metal (aluminum, aluminized steel, stainless steel, carbon steel), each with its own properties, advantages, and considerations.

Aluminum alloy metal is the best for even heat distribution, making it a popular choice for most home and commercial bakers.

Aluminized steel and stainless steel are more durable and less prone to warping or denting. Aluminized steel combines the best of both worlds (heat conductivity and strength). Stainless steel, while highly durable and resistant to rust, is expensive and not the most practical choice for commercial bakeries and food factories. Its lower heat conductivity compared to materials like aluminum or aluminized steel can lead to uneven baking, which is problematic in high-demand environments where consistency is key. Additionally, in the demanding, high-volume conditions of a food factory, stainless steel's weight and higher cost make it less efficient and cost-effective for large-scale production. Cheaper, more heat-efficient materials like aluminum and aluminized steel are often preferred for their ability to handle constant, high temperature baking tasks.

Carbon steel is likely used for home kitchen bakeware and cookware. It is made from iron and asmall percentage of carbon. It is similar to cast iron but thinner and more responsive to temperature changes. It conducts heat very well, offering quick and even heating. But compared to the previous three metals, its durability is far less good. So it is often used in household products. Tsingbuy commercial baking tray factory in China mainly provides aluminum, aluminized steel bakeware for commercial and industrial use. Meanwhile, we also provides stainless steel tray pan and carbon steel products (by providing ODM&OEM service to our clients).

What gauge is best for metal sheet pans?

The gauge of a metal sheet pan refers to its thickness, with a lower gauge number indicating a thicker pan. The ideal gauge for sheet pans depends on the type of material and baking recipe, but for commercial bakeries, food factories, or heavy-duty baking, a thicker pan is typically better for durability and even heat distribution.However, thicker trays are also more expensive and can be difficult to find. Here are some suggestions from Tsingbuy manufacturer:

Aluminized Steel Sheet Pans

- the preferred thickness is 0.5-0.8mm. If you're looking for a cookie pan that is both durable and cost-effective, choose one with a thickness in the 0.5-0.8 mm range, as it offers a good balance between strength and economy for commercial baking needs.

Aluminum Alloy Sheet Pans

- the most suitable thickness is 0.8-1.2mm. If you're seeking even heat distribution and quick cooling times, choose an aluminum tray within the 0.8-1.2 mm range, as it provides excellent performance for both baking and cooling efficiency.

Stainless Steel Sheet Pans

- the thickness should be at least 18-gauge (0.48mm). If you need a stainless steel tray that is both durable and offers excellent heat conductivity, choose one made from stainless steel with a thickness of at least 18-gauge (0.48 mm). This ensures strength and consistent performance in demanding baking environments.

Carbon Steel Sheet Pans

- the ideal thickness for carbon steel sheet pans is 0.4-0.7mm. This thickness makes them a cost-effective choice for baking needs, and provides a good balance of durability and performance, ensuring reliable results in the kitchen.

When choose the gause of a metal sheet pan, it is essential to prioritize even heat distribution without overspending.

Tips for using metal sheet pans?

1. Preheating and Temperature Considerations

Before baking, it’s crucial to preheat your oven to ensure even cooking and optimal browning of your food. Additionally, always follow the recommended baking temperatures in your recipes. Metal pans conduct heat efficiently, so you may need to adjust baking times or temperatures to achieve the best results. This practice not only enhances the quality of your baked goods but also prevents overcooking or undercooking.

2. Proper Preparation Techniques

To prevent sticking and facilitate easier cleanup, consider lining your sheet pans with parchment paper or silicone baking mats. This is particularly useful for baking delicate items like cookies and pastries. Furthermore, avoid overcrowding the pan; leaving enough space between items allows for proper air circulation, which promotes even cooking and prevents steaming.

3. Baking and Cooking Tips

During baking, it’s beneficial to rotate the sheet pan halfway through the cooking time, especially if your oven has hot spots. This simple step helps ensure that all sides of your food receive equal heat exposure, resulting in uniform cooking. Also, keep a close eye on your baked goods as they approach the end of the cooking time. Metal pans can cook items faster than glass or ceramic, so checking for it earlier can prevent burning.

4. Cleaning and Maintenance

After using your metal sheet pans, avoid soaking them in water, as this can lead to warping or rust, particularly in carbon steel pans. Instead, wash them promptly with warm, soapy water and dry them immediately to maintain their integrity. It’s also wise to use appropriate utensils when handling the pans—opt for silicone, wood, or plastic to avoid scratching nonstick or coated surfaces.

5. Storage and Use of Different Pans

When storing your sheet pans, stack them with a protective layer, like a kitchen towel, between each pan to prevent scratches and damage. Additionally, be mindful of the type of pan you’re using. Dark-colored pans absorb more heat and can brown items faster, while light-colored pans reflect heat, making them ideal for delicate baking. Choose the right type based on your specific baking needs for optimal results.

When should I replace my sheet pan?

1. Signs of Warping or Damage

One of the most obvious signs that it’s time to replace your sheet pan is warping or bending. A warped pan does not sit flat in the oven, leading to uneven cooking and baking. If you notice that your sheet pan has taken on a shape that prevents it from lying flat, it's a clear indication that its functionality has been compromised.

2. Scratches and Surface Damage

Severe scratches or damage to the surface of your sheet pan can also signal that it’s time for a replacement. For nonstick-coated pans, deep scratches or chips expose the base material, which can lead to food sticking and potential safety concerns. In aluminum or steel pans, surface scratches may affect food quality, making it essential to replace them if they become too worn.

3. Rust and Corrosion

Rust is a significant indicator that your sheet pan needs to be replaced, particularly for carbon steel or uncoated aluminum. The presence of rust not only affects the pan's appearance but can also pose food safety risks. If you see any signs of corrosion, it’s best to dispose of the pan to avoid compromising your baked goods.

4. Performance Issues

If you notice consistent problems with baked goods burning on the bottom or cooking unevenly, your sheet pan may be to blame. Over time, pans can lose their heat conductivity or nonstick properties, leading to poor baking results. If performance declines and your usual baking methods are no longer yielding good results, it may be time for a new pan.

5. Age and Maintenance Considerations

Lastly, consider the age of your sheet pan. Even with proper care, pans can degrade over time. If you’ve had a pan for several years and begin to notice issues like sticking or poor performance, it might be wise to invest in a replacement. Regularly assessing your sheet pans will help ensure that your kitchen tools remain effective, leading to consistently successful baking and cooking.

How to get custom made sheet pans for commercial bakery baking?

Tsingbuy bakeware manufacturer has been providing custom design and wholesale aluminum sheet pans world widely since 2006. We specialize in providing high-quality ODM&OEM services to meet the specific needs and requirements of our clients. Our team is dedicated to producing top-notch sheet pans that are not only durable and long-lasting but also efficient and affordable in commercial bakeries, food factories (suitable for automated production systems). If you are in need of commercial sheet pans for your business, we would be happy to assist you and provide you with the highest quality products and services. Here are some notes to improve our communication.

1. Determine Your Requirements

Specify Dimensions: Decide on the size and shape of the sheet pans you need (e.g., standard sizes like 18x26 inches or custom dimensions).

Choose Material: Select the material that best suits your baking needs, such as aluminum, aluminized steel, stainless steel, or carbon steel.

Gauge Thickness: Determine the appropriate gauge (thickness) based on your baking environment and requirements for durability and heat conductivity.

Design Features: Consider any specific design features you may want, such as reinforced edges, nonstick coatings, corrugated bottom, perforated bottom or custom logos.

2. Contact us

Provide Details and Reach Out:

click contact us page and you will get several method to talk with us. Please remember to leave your contact information(email/phone number/whatsAPP etc) so that we can provide you with timely feedback.

3. Request a Quote

After discussing your requirements, ask for a custom quote. Tsingbuy will typically provide pricing based on your specifications, including materials, sizes, and any additional features.

Inquire about minimum order quantities, lead times for production, and shipping options.

4. Review and Approve Designs

Tsingbuy may provide prototypes or design mock-ups based on your specifications. Review these designs carefully. Confirm that all details align with your requirements before moving forward. Ask for adjustments if necessary.

5. Place Your Order

Once you approve the design and quote, place your order with Tsingbuy. Make sure to clarify payment methods and delivery timelines. Keep communication open for any updates during the production process. And then waiting for shipment.