Perforated vs. Non-Perforated Sheet Pans: When to Use Each

Contents

- 1. Introduction

- 2. What Are Perforated Sheet Pans?

- 3. What Are Non-perforated Sheet Pans?

- 4. How to Choose: Key Considerations

- 5. Comparison

- 6. Customization Options with Tsingbuy

- 7. Conlusion

1. Introduction

Baking sheet pans—also known as flat baking trays or cookie sheets—are essential tools in every commercial bakery and food production facility. Designed for baking a wide range of products from pastries to bread and cookies, these pans come in various sizes, materials, and configurations to suit different baking needs and equipment setups.

Among the most important distinctions in sheet pan design is whether the pan is perforated or non-perforated. A perforated sheet pan features a surface with small holes that promote airflow and faster heat transfer, while a non-perforated pan has a solid surface that provides even heat distribution and prevents leakage of batters or oils.

In large-scale baking environments—such as commercial bakeries, food factories, and automated production lines—choosing the right type of sheet pan is not just a matter of baking preference. It directly impacts baking efficiency, product consistency, texture outcomes, and machine compatibility. Understanding the functional differences between perforated and non-perforated sheet pans allows bakeries to optimize their equipment setup, reduce baking time, and ensure product quality at scale.

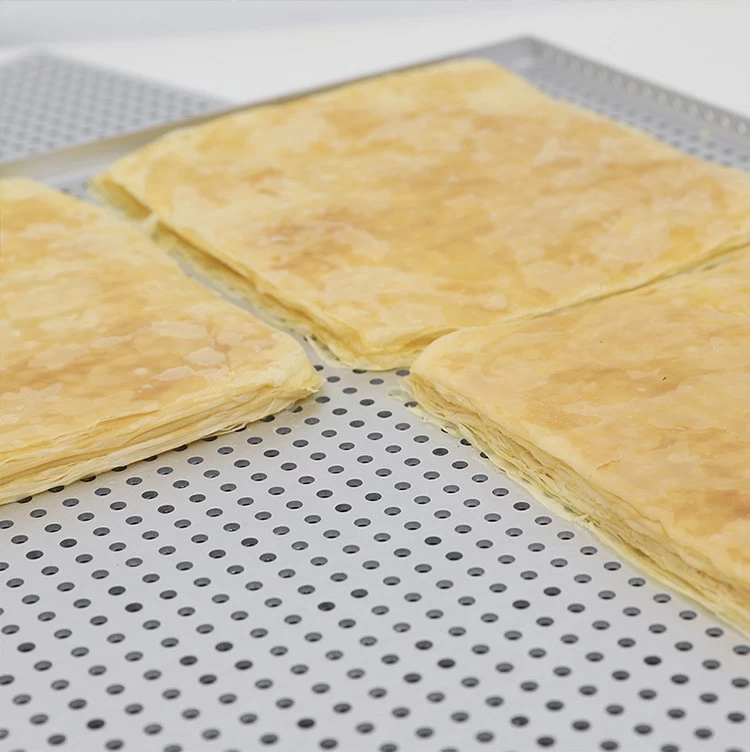

2. What Are Perforated Sheet Pans?

Perforated sheet pans are baking trays designed with a pattern of small, evenly spaced holes across the surface. These perforations serve a functional purpose—allowing heat and air to circulate more efficiently around the baked goods, resulting in faster, more uniform baking.

These pans are commonly made from aluminum or aluminized steel, both known for excellent thermal conductivity and durability in high-volume commercial settings. Aluminum is particularly favored for its lightweight nature and quick heat response, making it ideal for bakeries that prioritize speed and consistency.

● Key Design Features:

Hole size & pattern: Typically uniform in size and distribution, the holes are designed to balance air circulation without compromising the structure of delicate baked goods.

Rim & edge design: Perforated sheet pans may feature rimmed edges for added rigidity or flat edges for easy sliding in and out of ovens and racks, especially in automated production systems.

● Advantages of Perforated Sheet Pans:

Enhanced heat circulation ensures even browning and consistent baking results.

Crispier crusts are achieved, especially important for products like baguettes, croissants, and thin-crust pizzas.

Reduced baking time, which increases throughput and energy efficiency in commercial operations.

● Typical Applications:

Perforated sheet pans are widely used in the baking of:

- Artisan breads and crusty rolls

- Baguettes and croissants

- Puff pastries and laminated dough products

- Reheating or finishing par-baked and frozen dough items

They are particularly effective in convection ovens and high-temperature baking lines, where airflow and moisture release play a critical role in achieving professional results.

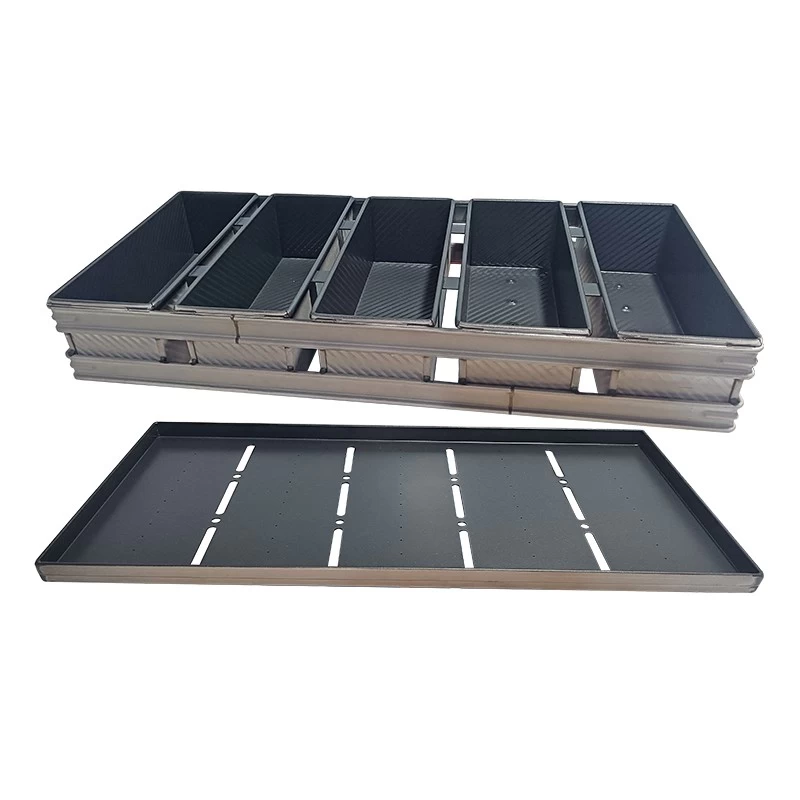

3. What Are Non-Perforated Sheet Pans?

Non-perforated sheet pans, also known as solid sheet pans, feature a continuous, unbroken surface without holes. These pans are commonly made from materials like aluminum or stainless steel and come in various shapes—most notably flat or rimmed (with raised edges). They may also have coatings (e.g., non-stick, silicone, or ceramic) to enhance food release and ease of cleaning.

● Advantages:

Even Heat Distribution: The solid surface ensures consistent baking, reducing hot spots.

Versatility: Ideal for both baking and roasting, from delicate desserts to savory dishes.

Leak Prevention: Raised edges contain batters, juices, and oils, making them perfect for liquid-heavy recipes.

● Typical Applications:

- Baking: Cookies, sheet cakes, brownies, and bar desserts.

- Roasting: Vegetables, meats, and poultry.

- Automated Systems: Used in commercial kitchens where batter or ingredient containment is essential.

Non-perforated pans are a kitchen staple due to their reliability and adaptability across cooking methods.

4. How to Choose: Key Considerations

Selecting between perforated and non-perforated sheet pans depends on several factors, including the food being prepared, equipment compatibility, and desired results. Here’s what to evaluate:

● Type of Product

Perforated pans: Best for dough-based items (e.g., bread, pizza) or foods requiring airflow for crispness.

Non-perforated pans: Ideal for batter-based goods (e.g., cakes, brownies) or recipes with liquids (e.g., roasted meats).

● Desired Texture

Crisp bottoms: Perforated pans promote airflow, enhancing browning and crunch.

Soft/even texture: Non-perforated pans retain moisture and heat gently.

● Oven Type

Convection/Deck ovens: Perforated pans work well with high airflow.

Rotary/rack ovens: Non-perforated pans prevent spills and suit multi-level baking.

● Speed & Volume

High-volume baking: Perforated pans may speed up cooking for certain items (e.g., pastries).

Large batches: Non-perforated pans offer stability for stacking and handling.

● Compatibility

Conveyor systems: Verify pan dimensions and rigidity (perforated pans may require reinforced edges).

Automated loading/unloading: Non-perforated pans are safer for liquid-heavy recipes.

Pro Tip: For mixed-use kitchens, keep both types on hand to maximize flexibility.

5. Comparison

| Criteria | Perforated Sheet Pan | Non-Perforated Sheet Pan |

| Best for | Bread, pizza, croissant | Cookies, cakes, roasting |

| Texture outcome | Crispier bottom | Softer, even bake |

| Suitable for convection? | Yes | Yes |

| Use on automatic lines? | Yes, if dough-based items | Yes, especially for batter |

6. Customization Options with Tsingbuy

At Tsingbuy sheet pan manufacturer in China, we understand that every bakery and food production line has unique needs. That’s why we offer tailored sheet pan solutions designed to optimize performance, efficiency, and compatibility with your equipment.

● Customization Features:

Perforation Patterns: Choose from standard or custom hole layouts (size, spacing, and shape) to control airflow for specific textures.

Pan Sizes & Depths: Tailor dimensions (full-size, half-sheet, etc.) and rim heights (flat, low, or high edges) to fit your oven or conveyor system.

Material & Coatings: Options include aluminized steel, stainless steel, or non-stick coatings for durability and easy release.

● Seamless Integration with Automation:

Our pans are engineered for smooth operation in:

Automatic loading/unloading systems.

Conveyorized ovens and rotary rack configurations.

High-speed production lines (compatible with industrial bakery machinery).

● ODM & OEM Services for Global Partners:

We collaborate with bakery equipment suppliers worldwide to provide:

Branded solutions (private labeling).

Bulk order adaptations (material thickness, reinforcement, etc.).

Technical support for machinery compatibility testing.

Why Tsingbuy perforated sheet pan factory in China? Precision engineering, fast prototyping, and scalable production—ensuring your sheet pans meet exact operational demands.

7. Conclusion

Choosing between perforated and non-perforated sheet pans directly impacts baking results, efficiency, and product consistency. The right selection depends on your product type (e.g., airy crusts vs. moist batters), oven setup, and production demands. While perforated pans excel in crispness and airflow, non-perforated pans offer versatility and containment for liquids or delicate bakes.

For commercial bakers, maintaining both types in your kitchen ensures flexibility across recipes—from artisanal breads to sheet cakes. Investing in high-quality, purpose-built pans minimizes waste, optimizes heat distribution, and streamlines workflow.

Need a tailored solution? Tsingbuy aluminum baking pan supplier in China specializes in custom sheet pans designed for your bakery or factory’s unique requirements—whether adjusting perforations, sizes, or materials for automated lines.