Custom Loaf Pan Solutions for Industrial Bakeries

Custom Loaf Pan Solutions for Industrial Bakeries: What to Consider

This article explores the key considerations when customizing loaf pans for high-volume production—covering size, material, coating, machine compatibility, branding, and more. Whether you’re scaling operations or upgrading equipment, discover how Tsingbuy’s custom loaf pan solutions can help you achieve seamless integration with your machinery system and deliver professional baking results at every batch.

Contents

- Introduction

- Why Custom Loaf Pans Matter in Industrial Production

- Key Factors to Consider in Custom Loaf Pan Design

- Compatibility with Machinery Production Systems

- Custom Branding & Identification

- Lead Time, MOQ, and Sample Making

- Why Choose Tsingbuy for Custom Loaf Pans

- Conclusion

1. Introduction

In industrial bakeries, where high output, consistency, and efficiency are non-negotiable, the choice of loaf pans directly impacts both product quality and production performance. Unlike standard bakeware, loaf pans used in large-scale operations must withstand intense daily use, integrate seamlessly with automated systems, and produce uniform results across hundreds or thousands of loaves.

That’s where custom loaf pan solutions become essential. From pan size and mold arrangement to coating type and structural reinforcement, customization allows bakeries to fine-tune their equipment to match specific dough formulas, baking methods, and production line configurations. This level of precision helps optimize throughput, reduce waste, and ensure consistency from batch to batch.

As a professional commercial bakeware manufacturer in China since 2006, Tsingbuy specializes in custom loaf pan manufacturing tailored for industrial bakeries and automatic machinery production systems. Whether you need strap loaf pans for sandwich bread, Pullman loaves, or unique cavity configurations for specialized recipes, Tsingbuy delivers efficient, durable, and fully customized solutions to meet your operational demands.

2. Why Custom Loaf Pans Matter in Industrial Production

In the context of industrial baking, where every second and every loaf counts, custom loaf pans are far more than just baking vessels—they are critical tools for optimizing efficiency, consistency, and profitability.

● High-Volume Consistency and Uniform Shape

Custom-designed loaf pans ensure that each bread product—whether it's a standard sandwich loaf or a specialty multigrain variant—maintains uniform shape, volume, and surface finish. This consistency is essential not only for meeting product quality standards but also for satisfying customer expectations in retail or foodservice channels.

● Seamless Compatibility with Automatic Production Lines

Industrial bakeries rely heavily on automated production systems, including dough dividers, molders, proofers, ovens, and cooling conveyors. Custom loaf pans can be engineered to align perfectly with these systems, ensuring smooth operation without jamming, misalignment, or downtime. Proper fit reduces mechanical wear and contributes to a longer lifespan for both pans and production equipment.

● Reduced Handling Time and Labor Cost

By optimizing pan configurations—such as the number of molds per strap, pan spacing, and stacking ability—custom loaf pans can significantly reduce manual handling and transfer steps. This streamlined workflow minimizes labor intensity, shortens turnaround time, and increases overall production speed.

● Tailored Designs for Specific Bread Types

Different bread types have different baking demands. A Pullman loaf, for example, requires a lid for square shape and soft crust, while a rustic multigrain loaf may benefit from a perforated mold for better airflow. Custom loaf pans can be tailored to the characteristics of specific recipes, improving final product quality and baking performance.

With these advantages, it becomes clear that investing in custom loaf pans is not just about convenience—it’s a strategic decision for industrial bakeries looking to scale efficiently while maintaining excellence in every batch.

3. Key Factors to Consider in Custom Loaf Pan Design

Designing custom loaf pans for industrial bakeries requires more than selecting a size or material. Every element—from the mold shape to the coating—should align with your specific production requirements. Below are the key factors that influence performance, durability, and compatibility in high-volume baking environments.

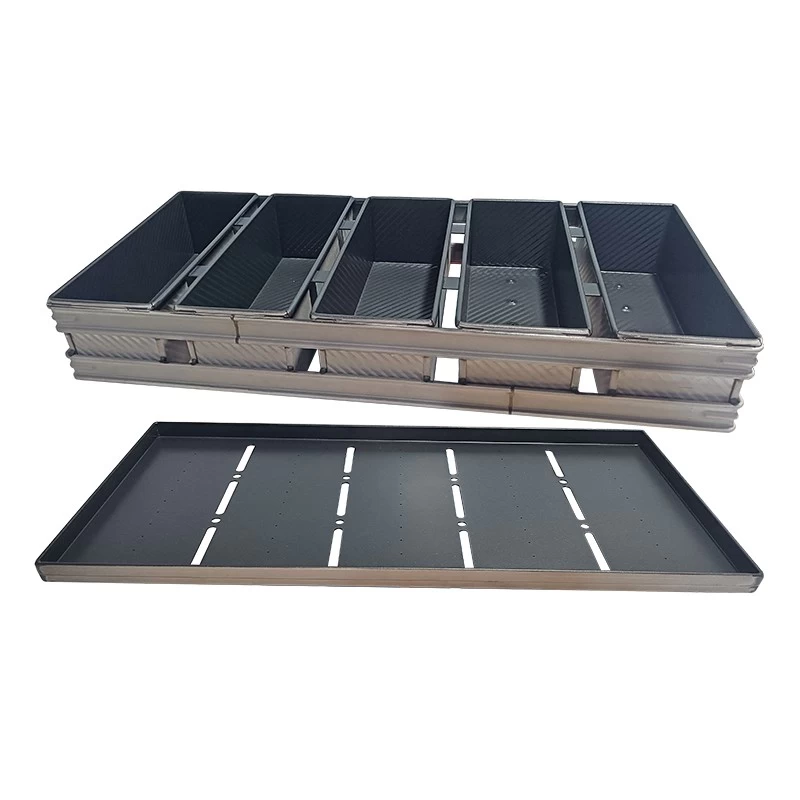

● Pan Size and Mold Configuration

The first consideration is the size of each cavity and the number of molds per strap. Industrial loaf pans are often grouped in configurations of 4, 6, 8, or more molds on a single strap to match the dimensions of your oven and automation system.

- Standard dough capacities may include 400g, 450g, 600g, or 1kg per loaf.

- Mold arrangement (in rows and columns) can be customized based on baking chamber size or conveyor layout.

- Pan height and sidewall angle can also affect crust development and loaf profile.

Custom configuration helps maximize tray space while maintaining airflow and uniform baking.

● Material Selection

Material choice affects heat transfer, weight, and longevity. Common options include:

- Aluminum: Lightweight, excellent heat conductivity, ideal for uniform browning.

- Aluminized Steel: More durable than pure aluminum, with added corrosion resistance.

- Stainless Steel: Highly durable and resistant to rust, best for wet doughs or high-moisture environments, though less conductive than aluminum.

Material selection depends on your baking style, cleaning procedures, and expected usage cycles.

● Surface Coating

Surface treatment is essential for loaf release, cleaning ease, and pan life. Tsingbuy offers a range of coating options, including:

- Teflon non-stick: Ideal for soft or sticky doughs; reduces cleaning effort.

- Silicone coating: Food-safe, flexible release, and commonly used in high-speed lines.

- Anodized aluminum: Offers a natural non-stick surface with no chemical coatings.

- Uncoated (bare metal): Preferred for bakers who rely on oiling and traditional crust development.

Choosing the right coating can improve efficiency and extend the usability of your pans.

● Pan Design Features

Details in mold geometry and construction can influence baking results and cleaning efficiency.

- Smooth vs. Corrugated Walls: Corrugation can enhance crust texture and reduce sticking.

- Perforated vs. Solid Bottoms: Perforations allow for moisture release and crisper crusts, suitable for rustic loaves or steam-assisted baking.

- Rounded vs. Sharp Corners: Rounded corners make cleaning easier, while sharp corners may be preferred for precise shaping.

These features can be fully tailored to suit your recipe and process needs.

● Strap Frame and Reinforcement

The frame holding the molds must be strong enough to handle repeated mechanical loading in automated systems.

- Thicker frames and reinforced welding add strength and prevent warping under high heat or pressure.

- Custom spacing between molds ensures proper airflow and even baking.

- Stacking compatibility is also important for transport, proofing, and storage systems.

Durability in both daily use and machine compatibility is key to long-term production success.

4. Compatibility with Machinery Production Systems

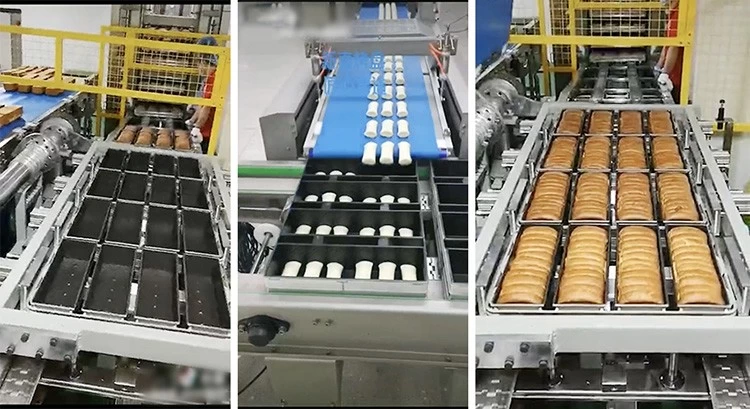

In modern industrial bakeries, loaf pans must do more than just bake bread—they must work seamlessly with the entire machinery production system. From dough deposition to baking, cooling, and demolding, every stage depends on precise alignment between the pan design and the equipment it runs on.

● Optimized Fit for Automation Lines

Custom loaf pans can be engineered to align with the dimensions and mechanics of automatic production lines, including:

- Dough depositors and molder

- Proofing cabinets and steam systems

- Rotary or tunnel ovens

- Cooling conveyors and demolding units

This alignment minimizes the chance of misfeeds, jamming, or uneven baking. It also ensures the pans move smoothly along the conveyor tracks and tray guides.

● Customized Dimensions and Pan Spacing

To match machine spacing and tray specifications, pans can be designed with:

- Precise mold placement and uniform gaps between cavities

- Overall tray size tailored to fit oven decks or proofer racks

- Stackable designs for automated loading/unloading systems

● Integration with Robotics and Pick-and-Place Systems

As more bakeries adopt robotics and automated handling arms, pan design must support reliable gripping, lifting, and rotation. Tsingbuy offers design adjustments such as reinforced frames, lifting lips, or secure locking edges for safe robotic integration.

● Light Customization for OEM Machinery

Tsingbuy also provides light customization services for bakeries using branded OEM equipment. Whether your system is from WP, Rademaker, or a regional machinery supplier, pans can be tailored to match your oven trays, belts, or stacking systems with precision.

By ensuring full compatibility between your custom loaf pans and your automated equipment, you reduce downtime, maintain consistent product quality, and improve the overall flow of production.

5. Custom Branding & Identification

In today’s competitive bakery market, custom loaf pans are not only tools for production efficiency—they also serve as a medium for brand identity, traceability, and quality control. Tsingbuy offers several customization options that help bakeries reinforce their brand presence and maintain operational clarity.

● Embossed or Stamped Logo

Adding your company logo or brand name directly onto the surface of the loaf pan is a simple yet powerful way to enhance brand recognition. This is especially valuable for:

- Chain bakeries and franchise operations

- Food factories with multiple production facilities

- OEM distributors offering private-label baking solutions

The embossed or stamped mark withstands high heat and cleaning, maintaining visibility throughout the product’s lifespan.

● Product Coding for Batch Tracking

Tsingbuy can also include custom identification codes, mold numbers, or batch information on pans. These small details are critical for:

- Traceability during production and quality control

- Tracking specific tooling batches in case of issues or recalls

- Ensuring correct pan usage for designated recipes or lines

Such identifiers help streamline factory operations, especially in facilities running multiple pan types or dough formulations.

● Private Label and OEM Services

For bakeware brands and commercial kitchen equipment suppliers, Tsingbuy offers OEM and private label services, including:

- Branded packaging

- Custom surface finishes

- Technical drawings marked with your logo and specifications

This allows you to market your own exclusive line of loaf pans without the need for in-house production.

Custom branding and marking are not only functional—they add professionalism, ensure accountability, and communicate quality to your clients and team. Tsingbuy loaf bread pan factory in China is equipped to provide these services with precision and flexibility, no matter your production scale.

6. Lead Time, MOQ, and Sample Making

When it comes to custom loaf pans, understanding the production timeline and order requirements is essential for planning your bakery operations. At Tsingbuy, we prioritize clear communication, efficient manufacturing, and flexible customization to help you bring your custom pan designs into reality.

● Minimum Order Quantity (MOQ)

Custom loaf pans typically require a minimum order quantity due to tooling and fabrication costs. The MOQ depends on the complexity of the design, materials used, and whether new molds or dies need to be developed.

- Standard MOQ starts at around 50–500 sets for most custom strap loaf pans.

- For complex or fully customized molds, MOQ may be negotiable because of the tooling expenses.

If you’re unsure whether your quantity meets the requirement, Tsingbuy's team is ready to evaluate your design and offer feasible options.

● Sample Development

Before full-scale production, a sample pan or mold prototype is usually produced for testing and confirmation. This is a critical step in ensuring that the pan performs correctly on your equipment and meets your product specifications.

- Custom samples can be fabricated based on your drawings or detailed requirements.

- Tsingbuy can also assist with design suggestions and generate 3D renderings or engineering drawings for approval before sample production.

Samples can be tested for bake performance, fit on automation lines, and ease of demolding—giving you confidence before moving into bulk production.

● Lead Time

Production lead time varies depending on the project’s complexity and order volume.

- Sample making usually takes 7–15 working days after final design confirmation.

- Mass production typically requires 20–35 working days, depending on material stock and manufacturing volume.

Urgent or time-sensitive projects can be discussed with Tsingbuy’s production team, who may offer prioritized scheduling where possible.

With transparent MOQ terms, professional sampling support, and reliable delivery schedules, Tsingbuy ensures a smooth and timely experience from concept to finished product. Our goal is to help your bakery move forward with confidence and minimal disruption.

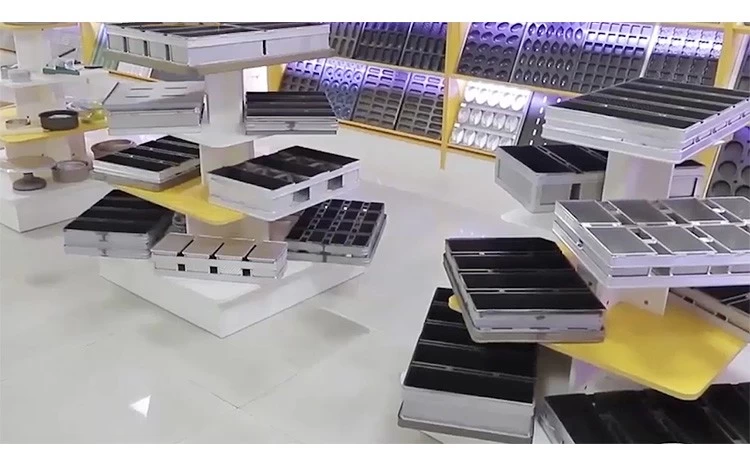

7. Why Choose Tsingbuy for Custom Loaf Pans

With nearly two decades of expertise in commercial bakeware manufacturing, Tsingbuy industrial baking pans supplier in China has become a trusted partner for industrial bakeries seeking high-quality, custom-designed loaf pans. Our strength lies not only in producing durable pans, but also in understanding the operational demands of large-scale baking and automated production systems.

● Extensive Experience in ODM & OEM Manufacturing

Since 2006, Tsingbuy has specialized in both ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services. We work closely with global clients to develop customized loaf pan solutions—from concept to mass production—based on unique recipes, machinery specifications, and production volumes.

● Wide Range of Customization Options

Tsingbuy offers full flexibility in pan customization, including:

- Cavity size, shape, and configuration

- Frame structure and reinforcement

- Material and surface coating choices

- Perforation patterns, wall texture, and branding details

Whether you're baking Pullman loaves, sandwich bread, or artisan multigrain, we can tailor every aspect of the pan to your needs.

● Compatibility with Automation Systems

We specialize in creating pans that are precisely engineered to integrate with conveyor ovens, proofers, and robotic handling systems. Our custom designs reduce production interruptions, improve line efficiency, and enhance overall consistency.

● Factory Supply with Competitive Pricing

As a direct factory supplier, Tsingbuy offers competitive pricing without compromising quality. We control every step of the manufacturing process, ensuring consistency, durability, and timely delivery.

● Light Customization and Flexible Service

In addition to full custom design, we also offer light customization options such as minor adjustments to standard molds, branding marks, or layout modifications—ideal for bakeries that need a quick, cost-effective solution with minimal lead time.

● Global Export and Trusted Client Base

Tsingbuy has served clients in over 50 countries, including food factories, commercial bakeries, and baking equipment distributors. Our reputation for quality and service has made us a long-term supplier for many global brands.

From the first inquiry to final delivery, Tsingbuy provides professional guidance, technical support, and reliable manufacturing for every custom loaf pan project. When you partner with us, you're choosing a team that understands the full scope of commercial baking needs.

8. Conclusion

In industrial baking, where efficiency, consistency, and equipment integration are essential, custom loaf pans are not just a preference—they're a necessity. From mold size and material selection to surface coatings and automation compatibility, every detail plays a role in optimizing your production line and delivering top-quality bread at scale.

By investing in custom loaf pan solutions, bakeries can reduce handling time, improve product uniformity, and enhance equipment performance—resulting in better yields and smoother operations. Whether you're baking Pullman loaves, sandwich bread, or specialty recipes, the right pan design makes a measurable difference.

With nearly 20 years of experience, Tsingbuy stands ready to support your bakery with tailored loaf pan solutions—offering full OEM & ODM service, expert engineering, and factory-direct production for both simple and complex requirements.

Reach out to Tsingbuy today to explore how we can help elevate your baking process with durable, precision-designed custom loaf pans built for industrial success.