How to Choose the Commercial Baguette Pan for Your Bakery?

Contents

- 1. Consider Your Production Scale

- 2. Choose the Right Material

- 3. Perforation Matters

- 4. Coating and Surface Treatment

- 5. Tray Design and Mold Shape

- 6. Customization Options

- 7. Ease of Cleaning and Maintenance

- 8. Supplier Quality and Support

A baguette pan is a specialized baking tray designed with multiple elongated molds to support the shaping and baking of French-style baguettes. In commercial bakeries, these pans are essential tools that help ensure consistent form, even baking, and high-quality crust texture across every batch.

Choosing the right commercial baguette pan is more than just selecting a tray—it directly affects your baking performance, operational efficiency, and product presentation. The pan's material, surface treatment, perforation, and mold configuration all contribute to how well your baguettes bake, how quickly they release, and how easily the pans integrate into your daily workflow or automatic production systems.

For bakeries focused on both quality and scalability, investing in the right baguette pan is a key decision that supports long-term success.

1. Consider Your Prodcution Scale

The first step in choosing the right commercial baguette pan is to assess your bakery’s production scale. Different baking environments require different pan configurations to ensure efficiency and consistency.

For small artisan bakeries, single or double-mold baguette pans may be sufficient. These are ideal for handcrafted processes where attention to detail, flexibility, and smaller batch sizes are prioritized. Artisan bakers often value the ability to manually shape and place dough with precision, making lightweight, easy-to-handle pans a practical choice.

In contrast, industrial bakeries and food factories operating on high-volume production schedules benefit from multi-mold strap pans, typically configured with 3, 4, 5, or even 6 molds per tray. These pans are designed for batch uniformity, faster turnaround times, and reduced labor handling, making them ideal for continuous, automated workflows.

Equally important is machine compatibility. If your bakery utilizes deck ovens, rotary ovens, or automated production lines, the baguette pans must match the machine’s tray size and positioning system. Custom dimensions may be necessary to ensure smooth integration, prevent misalignment, and optimize heat circulation within the oven.

Selecting a baguette pan that aligns with your production scale not only enhances efficiency but also contributes to consistent product quality and reduced operational downtime.

2. Choose the Right Material

Material selection plays a crucial role in the performance and longevity of a commercial baguette pan. Each material brings distinct characteristics that affect heat conduction, durability, and ease of use in a busy bakery environment.

● Aluminized Steel

Aluminized steel is one of the most popular materials for commercial baguette pans. It offers excellent durability, corrosion resistance, and consistent heat retention, making it well-suited for high-temperature, high-volume baking environments. Its steel core provides strength and rigidity, while the aluminum-silicon alloy coating enhances heat distribution and protects against rust.

- Pros: Long lifespan, strong structure, great for consistent baking.

- Cons: Slightly heavier than aluminum; may darken over time with repeated use.

● Aluminum

Aluminum baguette pans are known for being lightweight and highly conductive, allowing for quick and even heat transfer. This makes them ideal for bakeries that prioritize fast baking cycles and crust development. However, uncoated aluminum may be more prone to dents and surface oxidation if not properly maintained.

- Pros: Fast heat response, lightweight, easy to handle.

- Cons: Softer than steel, may require a non-stick or protective coating for longevity.

● Stainless Steel

Stainless steel pans are less common in standard baguette production but are sometimes used in custom or heavy-duty applications, especially where strength and corrosion resistance are critical. While they don’t conduct heat as efficiently as aluminum or aluminized steel, their durability and resistance to warping can be advantageous in certain industrial setups.

- Pros: Extremely durable, corrosion-proof, low maintenance.

- Cons: Poorer heat conductivity, heavier, more expensive.

When choosing the material for your baguette pan, consider the trade-offs between thermal performance, handling weight, and service life. For most commercial bakeries, aluminized steel strikes a practical balance, while aluminum is favored for faster baking and easier handling. Stainless steel is best suited for niche requirements or custom-designed industrial setups.

3. Performation Matters

One of the most defining features of a commercial baguette pan is whether it is perforated or non-perforated—a design choice that directly impacts the crust texture, baking time, and overall bread quality.

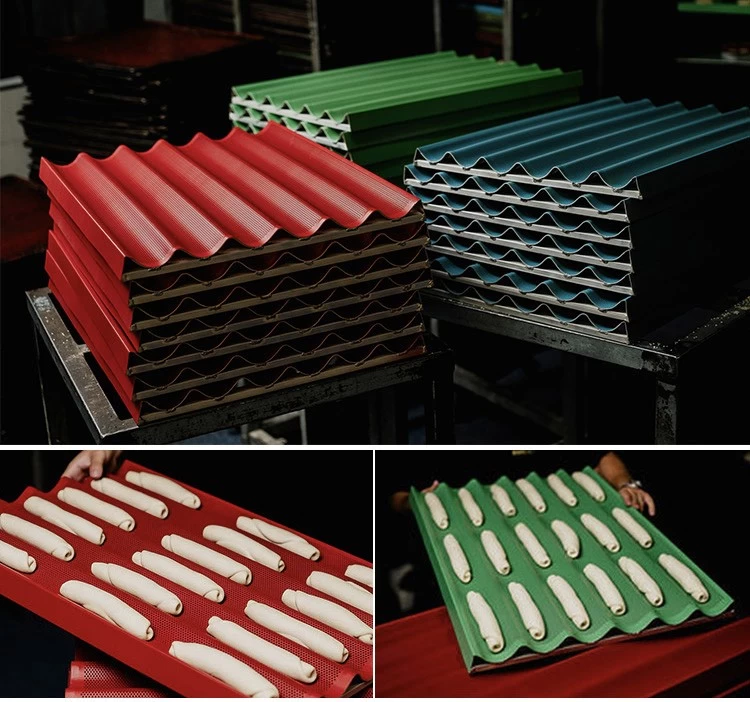

● Perforated Baguette Pans

Perforated pans are designed with small, evenly spaced holes across the surface of each mold. These perforations promote maximum airflow and moisture release during baking, which results in a thinner, crispier crust—perfect for traditional French-style baguettes.

The improved heat circulation also helps achieve uniform browning on the bottom and sides, enhancing the aesthetic appeal and texture of the final product. For artisan bakeries aiming to deliver authentic crustiness and character, perforated pans are typically the preferred choice.

Best for: Crispy crusts, golden color, artisan-style baguettes.

● Non-Perforated Baguette Pans

Non-perforated pans offer a solid mold surface, which retains more moisture in the dough and creates a softer crust. This is ideal for bakeries producing baguettes with a tender bite, or for recipes inspired by regional or customized bread styles that deviate from the traditional crispy profile.

These pans may also be preferable when baking with enriched doughs or when crust softness is desired for packaging and extended shelf life.

Best for: Softer crusts, specialty bread styles, packaging-friendly loaves.

When choosing between perforated and non-perforated baguette pans, consider the desired crust texture, type of dough, and customer expectations. Tsingbuy baguette pan factory in China even supplied many commercial bakeries with stock of both types to suit different recipes or seasonal product lines.

4.Coating and Surface Treatment

The surface treatment of a commercial baguette pan plays a vital role in both baking performance and maintenance efficiency. Whether coated or uncoated, the choice affects product release, cleaning time, and crust characteristics.

● Non-Stick Coating

Many commercial baguette pans are available with non-stick coatings, such as PTFE (Teflon) or silicone glaze. These coatings create a smooth, low-friction surface that allows baked loaves to release easily from the molds, minimizing tearing or sticking—especially important in high-volume operations.

Non-stick pans also significantly reduce cleaning time, enhance hygiene standards, and extend pan lifespan when maintained properly. This makes them ideal for bakeries prioritizing efficiency and sanitation in daily production.

Benefits: Quick product release, easy cleaning, less oil or flour needed for dusting.

Best for: Fast-paced commercial bakeries, automatic production lines, sticky or enriched doughs.

● Uncoated Pans

Uncoated baguette pans, while requiring more careful handling, are preferred by some artisan bakers for achieving a traditional crust texture. The raw metal surface promotes a slightly drier bake and helps develop a more rustic finish. These pans usually require seasoning or light greasing before use to prevent sticking.

While they may need more effort in cleaning, uncoated pans can also be more durable in the long term, as there's no coating to wear off.

Benefits: Classic baking results, longer life when seasoned properly.

Best for: Artisan-style baking, crust-focused recipes, traditional baguette presentation.

● Maintenance Considerations

Coated Pans: Avoid abrasive tools or harsh detergents to protect the non-stick layer. Use soft cloths or brushes and avoid high alkaline cleaning agents.

Uncoated Pans: Regular seasoning can build a natural release surface over time. Thorough drying after washing is essential to prevent corrosion, especially with aluminized steel.

Choosing the right surface treatment depends on your baking style, recipe types, and operational demands. While non-stick pans offer convenience and efficiency, uncoated pans provide more control over crust texture and a traditional finish.

5. Tray Design and Mold Shape

The design of the tray and the shape of the molds are critical details that influence both baking efficiency and final product consistency. Selecting the right mold configuration ensures smooth production flow and perfectly shaped baguettes, every time.

● Mold Count

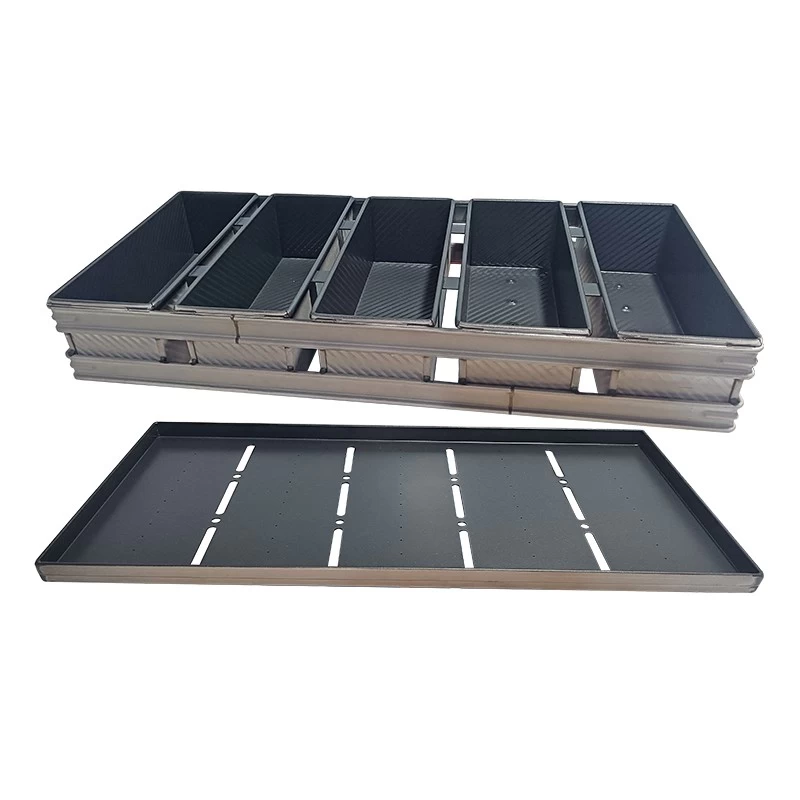

Commercial baguette pans are typically available in 2, 3, 4, 5, or 6-mold configurations, often referred to as strap pans. The appropriate mold count should match your daily batch size, oven capacity, and production pace.

- 2–3 molds: Ideal for small-scale or artisan bakeries with manual loading and lower output.

- 4–6 molds: Common in commercial bakeries aiming for high-volume, consistent baking with minimal handling.

Using strap pans with more molds per tray helps streamline the baking process, reduce labor, and improve batch uniformity—especially when used with racks or automatic conveyors.

● Mold Size

The length, width, and depth of each mold must align with your specific baguette recipe and product standard. For example:

- Traditional French baguettes require longer and shallower molds.

- Shorter or wider molds may be better for sandwich baguettes or regional variants.

Custom mold dimensions can also be tailored to fit your desired bread weight, shape, and crust profile, ensuring every baguette comes out consistently.

● Edge Design

Look for pans with reinforced or reverse-folded edges, which add structural stability and help the tray maintain its shape under high heat or frequent use. These design features are especially important in commercial kitchens and automated systems, where repeated tray movement and stacking are common.

Well-constructed edges also prevent warping and extend the overall service life of the pan, making them a smart long-term investment.

Choosing the right tray design and mold shape is essential for achieving consistent results, efficient handling, and durable performance—whether you’re producing a few dozen loaves a day or thousands in an industrial setting.

6. Customization Options

In commercial baking, customization can make a significant difference in optimizing workflow, improving product consistency, and ensuring compatibility with your bakery’s equipment. Choosing a supplier that offers flexible customization options allows you to adapt your baguette pans precisely to your production needs.

● Tailored Dimensions

Standard pan sizes don’t always align perfectly with the dimensions of your ovens, racks, or conveyor systems. Customizing the overall tray size, mold dimensions, and tray spacing ensures seamless integration with:

- Rotary or deck ovens

- Tunnel ovens

- Rack trolleys and proofing systems

- Automated conveyor lines

This precision fit minimizes production interruptions, maximizes oven space utilization, and helps maintain uniform heat distribution across all loaves.

● Custom Mold and Perforation Design

Customization also extends to the number of molds per tray, mold shape, and perforation pattern. You can adjust:

- Mold count and spacing to suit different baguette lengths or batch requirements

- Perforation layout for specific crust textures and airflow control

- Depth and curvature for specialty or regional baguette styles

These custom details help bakeries produce signature products with consistent quality at scale.

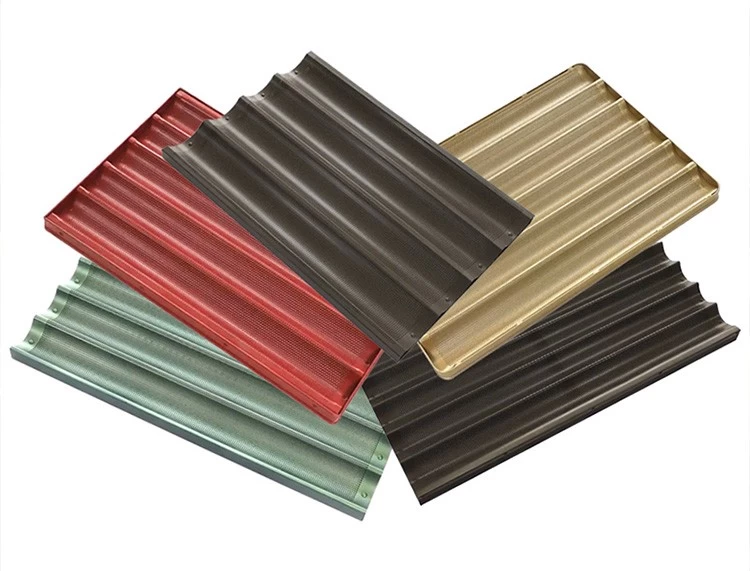

● Branding and Visual Identity

Many commercial bakeries choose to reinforce brand identity by adding logo embossing or custom markings to their pans. This not only reflects professionalism but also helps with internal tray tracking and inventory control.

● ODM & OEM Services

For bakeries operating within fully automated or semi-automated machinery production systems, it’s crucial to work with a manufacturer that offers ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services. This enables complete customization of baguette pans to match proprietary equipment, including:

- Special tray locking mechanisms

- Unique mold designs

- Integration into robotic loading/unloading systems

Whether you're looking to optimize for machine compatibility, enhance baking results, or showcase your brand, investing in custom-designed baguette pans ensures your equipment works exactly the way your bakery needs it to.

7. Ease of Cleaning and Maintenance

Maintaining commercial baguette pans in optimal condition is essential not only for hygiene but also for ensuring consistent baking performance and extending the lifespan of your investment. The surface treatment of the pan significantly influences cleaning time and maintenance requirements.

● Impact of Surface Treatment on Cleaning

Non-stick coated pans (such as PTFE or silicone glaze) offer a smooth surface that prevents dough from sticking, making cleaning faster and easier. These coatings reduce the need for harsh scrubbing, saving labor time and protecting the pan’s integrity.

Uncoated pans, while delivering traditional crust textures, may require more thorough cleaning and occasional seasoning to prevent buildup and sticking. Regular maintenance is critical to avoid corrosion, especially with aluminized steel pans.

● Tips to Prolong Pan Life

- Always allow pans to cool before cleaning to prevent warping caused by sudden temperature changes.

- Avoid abrasive scrubbers or metal utensils that can damage coatings or scratch the pan surface.

- Use mild detergents and soft brushes or cloths for cleaning.

- For uncoated pans, consider periodic seasoning by applying a thin layer of oil and baking at a moderate temperature to maintain a natural release surface.

- Ensure pans are thoroughly dried after washing to prevent rust or corrosion.

● Food-Grade, FDA-Approved Finishes

Using pans with food-grade, FDA-approved coatings and materials is critical for safety and regulatory compliance in commercial baking. These finishes ensure that no harmful substances leach into your baked goods and that your bakery meets hygiene standards required by health authorities.

Proper cleaning and maintenance practices combined with the right surface treatment not only safeguard your bakery’s health standards but also help maintain consistent baking quality and maximize the service life of your commercial baguette pans.

8. Supplier Quality and Support

Choosing the right baguette pan isn’t just about the product—it’s also about the quality of the supplier behind it. A reliable and experienced manufacturer ensures that the pans you receive meet professional standards in durability, precision, and consistency, while also offering the flexibility to support your bakery’s evolving needs.

● Proven Experience Matters

Look for suppliers with a strong track record in manufacturing commercial-grade bakeware, particularly those who specialize in products designed for high-volume bakeries and automated production systems. An experienced supplier understands the technical demands of modern baking environments, from pan structure to oven compatibility.

● Key Services to Expect

A dependable supplier should provide:

- Sample testing before mass production to ensure design accuracy and performance suitability.

- Low minimum order quantities (MOQs) for custom pans, helping both growing bakeries and large-scale factories manage cost and inventory.

- Responsive after-sales support, including technical assistance and warranty options.

These services are especially valuable when you’re investing in custom-designed pans tailored to your machinery, production flow, or specific bread style.

● Why Choose Tsingbuy

As a professional bakeware manufacturer with nearly two decades of experience, Tsingbuy industrial baking tray supplier in China has become a trusted partner for commercial bakeries worldwide. We specialize in producing custom baguette pans with precise specifications to match:

- Manual or automatic baking operations

- Rotary, deck, or tunnel ovens

- Specific mold shapes, perforation patterns, and branding needs

With a complete ODM & OEM service system, sample confirmation procedures, and dedicated support throughout the order cycle, Tsingbuy delivers solutions that are both practical and high-performing.

Conclusion

Selecting the right commercial baguette pan involves more than just choosing a mold—it requires thoughtful consideration of several key factors, including material, perforation, coating, mold design, and production scale. Each element plays a vital role in the quality of your final product and the efficiency of your bakery operations.

By evaluating your baking style, batch size, and equipment compatibility, you can determine which type of baguette pan best supports your daily workflow—whether you're running a small artisan shop or a fully automated industrial bakery.

Ultimately, investing in high-quality, well-designed baguette pans tailored to your production needs leads to better consistency, reduced labor, and long-term cost savings. Choosing a trusted and professional French bread tray manufacturer in China like Tsingbuy ensures you not only receive durable bakeware but also benefit from expert guidance, customization options, and dependable support.

Let your baguette pans work as hard as you do—crafted for performance, built for the demands of commercial baking.