How to Choose the Right Industrial Cupcake Pan?

How to Choose the Right Industrial Cupcake Pan: Shapes, Materials, Custom Options & Manufacturer Guide

This article is a comprehensive guide for bakery professionals and food production managers looking to choose the right industrial cupcake pans. From exploring standard and creative mold shapes to understanding materials, tray construction, and customization options, you'll gain valuable insights into selecting pans that improve baking efficiency, consistency, and product appeal. Learn why Tsingbuy is the trusted manufacturer for commercial-grade cupcake trays tailored to automatic production lines and high-volume operations.

Contents

1. What is an Industrial Cupcake Pan?

2. Available Cupcake Mold Shapes for Commercial Use

3. Materials & Construction: What Makes a Good Industrial Cupcake Tray?

4. Customization Options to Match Your Bakery Needs

5. Industrial Cupcake Pan Applications

6. Tips for Choosing the Right Cupcake Pan

7. Why Choose Tsingbuy as Your Industrial Cupcake Pan Manufacturer

9. Frequently Asked Questions (FAQ)

1. What is an Industrial Cupcake Pan?

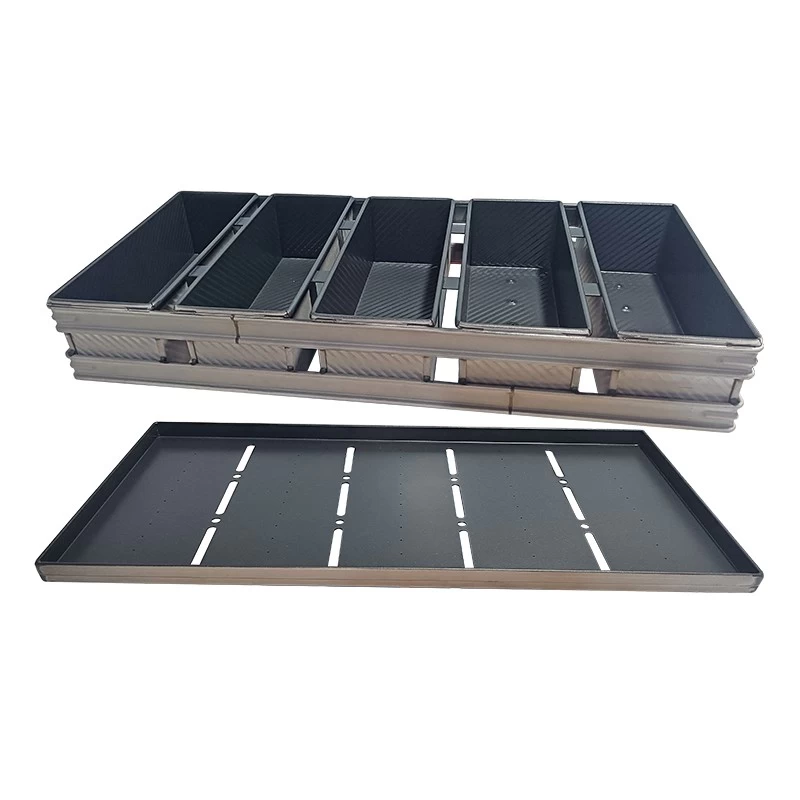

An industrial cupcake pan is a heavy-duty baking mold specifically designed for high-volume commercial baking operations. Unlike lightweight home-use cupcake trays, industrial pans are built to withstand continuous use in food factories, central kitchens, and large-scale bakeries. They are engineered for durability, heat efficiency, and consistent baking results, even under the demanding conditions of automatic production lines.

These pans typically feature multiple cavities arranged in tightly spaced configurations to maximize output per bake cycle. The construction materials—such as aluminized steel with reinforced frames—ensure the pans resist warping, support uniform heat distribution, and deliver consistent product shapes and textures. Industrial cupcake pans are often customized to fit automated machinery, including robotic filling, baking, and demolding systems.

Whether used for classic cupcakes, muffins, or uniquely shaped treats, industrial cupcake trays play a critical role in streamlining production, reducing labor, and ensuring repeatable quality in every batch.

2. Available Cupcake Mold Shapes for Commercial Use

When it comes to industrial cupcake pan shapes, versatility is key. In large-scale baking operations, the shape of each cupcake mold isn't just about aesthetics—it directly impacts product identity, packaging compatibility, and customer appeal. At Tsingbuy, we offer a wide range of standard and custom cupcake mold shapes to suit both functional and creative baking requirements.

2.1. Most Common Shapes in Commercial Production

Round – The timeless and most widely used shape. It offers optimal heat distribution and is compatible with most automated production lines and packaging systems.

Square – With its neat, geometric design, the square cupcake mold brings a modern touch to desserts and allows for efficient arrangement in trays and boxes.

Rectangle – Ideal for mini loaf cakes or cupcakes with fillings. Its longer profile accommodates layered or filled batter designs for a premium product offering.

Oval – A more sophisticated shape often used in boutique bakeries or for specialty products that require a unique presentation.

Heart – Popular for romantic or festive themes, heart-shaped cupcake molds create strong visual impact and emotional connection, making them ideal for Valentine’s Day or weddings.

2.2. Creative & Festive Shapes for Custom Appeal

Beyond the classics, industrial bakeries often require molds that deliver visually distinctive products:

Star, Flower, Cartoon, and Holiday-Themed Molds – Perfect for seasonal promotions, children’s products, or themed packaging.

These creative shapes are commonly used in gift boxes, limited-edition collections, and promotional campaigns, helping brands capture attention and enhance product storytelling.

2.3. Why Shape Matters in Industrial Baking

The shape of the mold not only affects the visual presentation but also:

Impacts baking consistency, as different shapes require careful heat balance.

Determines packaging layout, which affects transport, shelf presence, and branding.

Engages customers visually, especially in competitive retail and café markets.

Supports brand identity, allowing businesses to stand out with signature designs.

At Tsingbuy industrial cupcake pan factory in China, we help our clients select or develop the ideal cupcake mold shape to align with their product concept, brand image, and automatic production requirements—whether for traditional cupcakes or uniquely shaped specialty desserts.

3. Materials & Construction: What Makes a Good Industrial Cupcake Tray?

Choosing the right material and construction is critical when selecting an industrial cupcake tray. Unlike light-duty household bakeware, commercial trays are engineered for high-frequency baking, uniform results, and long-term durability—especially when integrated into automatic production lines. Here’s what sets high-quality industrial cupcake pans apart:

3.1. High-Performance Materials

Aluminized Steel

A top choice for commercial baking pans, aluminized steel combines the heat conductivity of aluminum with the strength and corrosion resistance of steel. It delivers excellent baking consistency, resists warping under high temperatures, and maintains shape through repeated cycles.

Aluminum

Lightweight and highly conductive, aluminum pans heat up and cool down quickly. They are ideal for operations requiring speed and energy efficiency. However, they may require reinforced support structures for heavy-duty use.

Reinforced Stainless Steel Frames

Many industrial cupcake trays incorporate stainless steel framing around the perimeter or base to provide rigidity and stability, especially for large-format trays used in food factories or rack ovens.

3.2. Non-Stick Coatings for Better Release & Efficiency

Teflon Coating

Offers a smooth, highly non-stick surface that ensures cupcakes release cleanly without residue. This reduces product damage, minimizes waste, and shortens cleaning time.

Silicone Glaze

A food-grade silicone coating that balances non-stick performance with a more natural surface. It’s suitable for high-temperature baking and helps preserve the product’s texture.

Uncoated (Natural Finish)

Suitable for certain applications where coating is not necessary or permitted. These pans rely more on greasing or paper liners.

All coatings used by Tsingbuy are food-grade and comply with international safety standards such as FDA and LFGB.

3.3. Key Construction Features

Consistent Cavity Forming

Precision-molded cavities ensure even shapes and sizes across every batch—essential for packaging, branding, and automation.

Gauge Thickness

Industrial pans are typically made from heavier-gauge metal to resist denting, bending, or warping. This contributes to longer lifespan and better baking stability.

Edge Design

Reinforced or curled edges improve handling strength and tray stacking, while reducing risk of injury during fast-paced operations.

Welded or Seamless Integration

Smooth joints and high-quality welding eliminate crevices where food can build up, improving sanitation and durability.

3.4. Built for Automation

A good industrial cupcake tray is not only about material quality, but also about how it fits into a machinery-driven workflow:

- Compatible with automatic depositor machines

- Aligned with conveyor or rotary oven tray sizes

- Designed for rapid loading/unloading and cleaning

At Tsingbuy, every cupcake tray is engineered to meet the demands of commercial baking, combining superior material choices, thoughtful construction, and optional customization to fit your production system perfectly.

4. Customization Options to Match Your Bakery Needs

In commercial and industrial baking, one-size-fits-all rarely delivers optimal results. That's why customization plays a critical role in selecting the right industrial cupcake tray—ensuring seamless integration with your recipes, baking equipment, and production volume. At Tsingbuy, we offer a full range of customization services to help bakeries, food factories, and machinery brands get bakeware that fits their exact needs.

4.1. Customizable Features of Industrial Cupcake Trays

Cavity Shape & Size

Choose from standard round, square, or rectangular cavities—or request custom shapes like heart, star, flower, or themed designs. Cavity diameter and depth can be precisely adjusted to match your product weight and fill level.

Number of Cavities per Tray

Whether you need 6, 12, 24, or more cavities per pan, we tailor the tray configuration to suit your oven size, automation system, and production capacity.

Tray Dimensions

Adjust the full tray size to match your oven deck, conveyor belt, or rotary rack dimensions. This ensures smooth handling and compatibility with existing equipment.

Surface Coating

Select the right coating based on your product and cleaning requirements:

- Teflon or PTFE non-stick coating for smooth release

- Silicone glaze for durability and moderate non-stick

- Uncoated natural finish for traditional baking styles

Reinforced Frame & Edge Design

Customize rim types (flat, curled, or wire-injected) to improve stacking, loading, and durability—especially important in high-speed, high-volume operations.

Perforation & Ventilation

Add perforated base or sides to improve airflow and ensure even baking, especially in ovens with steam or convection systems.

Logo Stamping & Branding

Add your brand logo or product code via embossing, etching, or laser marking for traceability and brand consistency.

4.2. Customization Workflow at Tsingbuy

At Tsingbuy, our customization process is collaborative, efficient, and quality-driven:

Needs Consultation – Understand your bakery’s equipment, product style, and operational goals.

Concept Design – From your sketch or idea, we produce technical drawings and 3D models.

Sample Production – A prototype is created and tested for form, fit, and baking performance.

Approval & Mass Production – Once confirmed, we move to full-scale manufacturing with consistent quality control.

Packaging & Delivery – Optimized packaging for international logistics and safe handling.

4.3. Flexible for OEM & ODM Projects

Whether you’re a commercial bakery, a food equipment supplier, or launching a new dessert product line, we welcome OEM and ODM projects with full support from design to delivery. From a custom cavity design to a tray that perfectly fits your automatic depositor or rotary oven, Tsingbuy cupcake baking tray supplier in China ensures your custom baking pans are not just tools—but assets that help you bake smarter, faster, and better.

5. Industrial Cupcake Pan Applications

Industrial cupcake pans are essential components in the workflow of commercial bakeries, food production plants, and centralized kitchens. Designed to handle high baking volumes while maintaining product consistency, these pans support various cupcake, muffin, and specialty dessert production needs. Their durability and adaptability make them indispensable in both manual and fully automated systems.

5.1. Where Industrial Cupcake Pans Are Used

Commercial Bakeries

Ideal for producing cupcakes, muffins, and mini cakes in large quantities with uniform size, shape, and finish—especially for wholesale or retail packaging.

Central Kitchens & Commissaries

Used in mass meal preparation for cafes, restaurants, hotels, and convenience food suppliers, where efficiency and hygiene are top priorities.

Food Manufacturing Plants

Integrated into automatic production lines for high-speed batter depositing, baking, and demolding. Pans are often customized to work seamlessly with robotics and conveyor systems.

Franchise Bakery Chains

Enable consistency across multiple outlets by using standardized molds that produce identical products—essential for brand integrity.

Dessert Processing Facilities

Useful in operations producing filled, shaped, or decorated cupcakes, including holiday-themed, kids’ treats, or branded promotional items.

5.2. Product Types Made with Industrial Cupcake Pans

Classic Cupcakes & Muffins

Baked in standard round molds for individual packaging or bulk sale.

Mini Loaf or Filled Cakes

Often produced in rectangular or oval molds, these are popular in gourmet or filled product lines.

Shaped or Themed Desserts

Heart, star, flower, and cartoon molds help diversify offerings and target niche markets, especially during holidays or product promotions.

Savory Applications

Pans can also be used to bake mini quiches, egg bites, or bread-based snacks in round or custom cavities, depending on the menu.

5.3. Compatible with Automation

Tsingbuy’s industrial cupcake pans are designed to match a wide range of bakery machinery, such as:

- Automatic batter depositors

- Rotary and convection ovens

- Cooling conveyors and demolding systems

- Rack trolleys and tray stackers

This compatibility ensures that your baking process is not only efficient but also scalable as your business grows.

By choosing the right cupcake pan setup for your specific application, you can achieve better baking results, higher output, and fewer losses—which all translate to stronger product performance and lower production costs.

6. Tips for Choosing the Right Cupcake Pan

Selecting the right industrial cupcake pan is more than just picking a shape or size—it’s about aligning your bakeware with your production process, product goals, and long-term efficiency. Below are key factors to consider when making your decision:

✅ 6.1. Match the Mold Shape to Your Product and Brand

- Classic round molds are ideal for standard cupcakes and muffins.

- Square, rectangular, or oval molds support differentiated product lines.

- Heart or themed shapes are great for seasonal items or brand-specific designs.

- The shape also impacts customer perception, packaging fit, and shelf presentation.

✅ 6.2. Choose the Right Material and Coating

- Use aluminized steel or reinforced aluminum for heavy-duty use and uniform heat conduction.

- Select a non-stick coating (Teflon or silicone glaze) for clean release and minimal residue.

- Consider uncoated pans if you use paper liners or have specific coating restrictions.

✅ 6.3. Ensure Tray Size Fits Your Oven and Machinery

- Confirm that the tray dimensions are compatible with your rotary oven, rack oven, or conveyor system.

- If you're using an automatic depositor, make sure cavity alignment and spacing are machine-compatible.

✅ 6.4. Pick the Right Number of Cavities

- Choose based on production volume and handling convenience.

- Higher cavity counts (e.g., 24+) increase output per cycle but may be heavier and harder to handle manually.

- For automation, cavity layout should align with your robotic or conveyor setup.

✅ 6.5. Consider Your Product's Moisture and Texture

- Dense or sticky batters benefit from non-stick coatings for easy demolding.

- For moist cakes or savory items, perforated designs may help improve airflow and crust texture.

✅ 6.6. Don’t Overlook Cleaning and Maintenance

- Trays with smooth welds and seamless construction are easier to clean and more hygienic.

- Non-stick coatings reduce scrubbing time and water use.

- Sturdy edge design and rust-resistant material help maintain tray integrity over time.

✅ 6.7. Plan for Growth and Scalability

- Choose trays that are compatible with future machinery upgrades or production line expansions.

- Consider modular tray designs that work across multiple products or baking systems.

Making a smart, informed choice ensures not only consistent product quality, but also greater efficiency, reduced waste, and longer-lasting equipment—saving time and cost in the long run. At Tsingbuy, our team provides personalized advice and technical support to help you select or customize the best cupcake tray solution for your production environment.

7. Why Choose Tsingbuy as Your Industrial Cupcake Pan Manufacturer

When it comes to sourcing reliable and high-performing industrial cupcake pans, choosing the right manufacturer makes all the difference. With nearly two decades of experience in commercial bakeware manufacturing, Tsingbuy stands out as a trusted partner for bakeries, food factories, and baking equipment brands around the world.

✅ 7.1. Nearly 20 Years of Expertise in Bakeware Manufacturing

Tsingbuy has specialized in the design and production of commercial-grade baking pans since 2006. Our deep understanding of industrial baking needs allows us to offer products that meet the rigorous demands of high-output, continuous-use environments.

✅ 7.2. Full Customization Capabilities

Whether you need custom shapes, tray sizes, cavity configurations, or specialized coatings, Tsingbuy provides OEM and ODM solutions to match your exact requirements. From initial design to mass production, our team ensures every detail supports your production goals and brand identity.

✅ 7.3. Built for Automation and Efficiency

Tsingbuy cupcake pans are designed to integrate seamlessly with modern bakery automation systems—including rotary ovens, automatic depositors, conveyors, and robotic demolders. We help optimize your equipment compatibility and improve baking efficiency from start to finish.

✅ 7.4. High-Quality Materials and Finishing

We use food-grade aluminized steel, aluminum, and reinforced stainless steel frames to guarantee durability, thermal stability, and corrosion resistance. Our coating options—such as Teflon, silicone glaze, or uncoated finishes—are all compliant with international food safety standards (FDA, LFGB).

✅ 7.5. Proven Global Experience

Tsingbuy serves clients across North America, Europe, the Middle East, Southeast Asia, and beyond. Our industrial cupcake pans are widely used in:

- Central kitchens

- Commercial bakery chains

- Food production factories

- Bakery equipment OEM brands

We’re experienced in international logistics, bulk packaging, and long-term supply for global distribution.

✅ 7.6. One-Stop Service from Concept to Delivery

From idea to execution, Tsingbuy offers professional consultation, rapid sampling, quality control, and secure shipping. Whether you're launching a new product line or upgrading existing bakeware, we’re committed to being a responsive and resourceful partner.

By choosing Tsingbuy bakeware manufacturer in China, you gain more than just a supplier—you gain a strategic manufacturing partner dedicated to helping your bakery business grow through precision-engineered, high-performance baking solutions.

8. Conclusion

Choosing the right industrial cupcake pan is essential for any commercial bakery or food production facility aiming to achieve consistent quality, high efficiency, and product uniqueness. From selecting the perfect mold shape and durable materials to leveraging expert customization, every detail influences your baking success.

At Tsingbuy, we combine nearly 20 years of industry experience with advanced manufacturing capabilities to provide customized, commercial-grade cupcake pans that perfectly fit your production line and brand vision. Whether you need standard trays or specialty molds, our solutions are designed to enhance your productivity and elevate your product appeal.

Ready to bake smarter and grow your business? Contact Tsingbuy today for professional advice, sample requests, and custom orders—let’s create the perfect industrial cupcake pans tailored just for you.

Frequently Asked Questions (FAQ)

Q1: Can you make cupcake pans for automatic machines?

A: Yes. Tsingbuy specializes in manufacturing industrial cupcake pans that are compatible with automatic production systems, including batter depositors, rotary ovens, conveyor lines, and demolding machines. We can customize tray dimensions, cavity layout, and structural design to align precisely with your machinery requirements.

Q2: What’s the minimum order quantity (MOQ) for custom shapes?

A: The MOQ for custom-shaped cupcake pans typically starts at 300 pieces, depending on the complexity of the design and materials used. For large-scale or machinery-integrated trays, we offer flexible options and can discuss a suitable MOQ based on the customization options included.

Q3: How long does it take to make a sample?

A: Sample production usually takes around 7–15 working days, depending on the complexity of the customization (shape, coating, dimensions, etc.). After confirmation of design and specifications, we proceed quickly to ensure your testing and approval timeline stays on track.