Looking for a Custom Commercial Croissant Pan?

Looking for a Custom Commercial Croissant Pan? Here's What to Consider

Contents

- What is a Commercial Croissant Pan?

- Key Features to Look For

- Compatibility with Industrial Production Systems

- Why Customization Matters

- Tsingbuy: Your Reliable Manufacturer for Custom Commercial Croissant Pans

- Conclusion: Get the Perfect Fit for Your Bakery Production Line

In the world of commercial baking, consistency, efficiency, and quality are non-negotiable. Whether you operate a central kitchen, an industrial food factory, or a busy bakery, the right baking equipment makes all the difference. Among the essential tools is the commercial croissant pan — a specialized baking tray that ensures uniform shape, texture, and baking results for large volumes of croissants.

If you're looking for a croissant pan that fits seamlessly into your production system and supports high-performance output, customization is key. In this article, we’ll explore what to look for in a commercial croissant pan, how customization benefits your operation, and why Tsingbuy bakeware manufacturer in China is your trusted manufacturer for tailor-made solutions.

1. What is a Commercial Croissant Pan?

A commercial croissant pan is a specialized baking tray engineered for shaping and baking croissants in high volumes. Unlike standard flat trays, these pans feature molded cavities or contoured forms that ensure uniform shape, size, and appearance—key factors in professional baking environments where product consistency is critical.

Commercial croissant pans are widely used in:

- Commercial bakeries

- Industrial food production facilities

- Automatic machinery production lines

- Conveyor and rotary baking ovens

Designed to withstand intensive use, high baking temperatures, and rapid production cycles, these pans are built to deliver long-lasting performance while meeting the strict demands of industrial baking.

a. Material Quality

The choice of material plays a crucial role in the pan’s heat conductivity, durability, and baking performance. Commercial croissant pans must endure continuous, high-volume use without warping or deteriorating. Commonly used materials include:

- Aluminized Steel – Offers excellent heat distribution and strong resistance to rust and corrosion. Ideal for consistent baking results.

- Aluminum – Lightweight and highly conductive, making it perfect for quick, even baking.

- Stainless Steel – Extremely durable and corrosion-resistant, well-suited for heavy-duty industrial applications.

For commercial use, selecting a pan with the right material ensures long-term reliability and consistent baking quality.

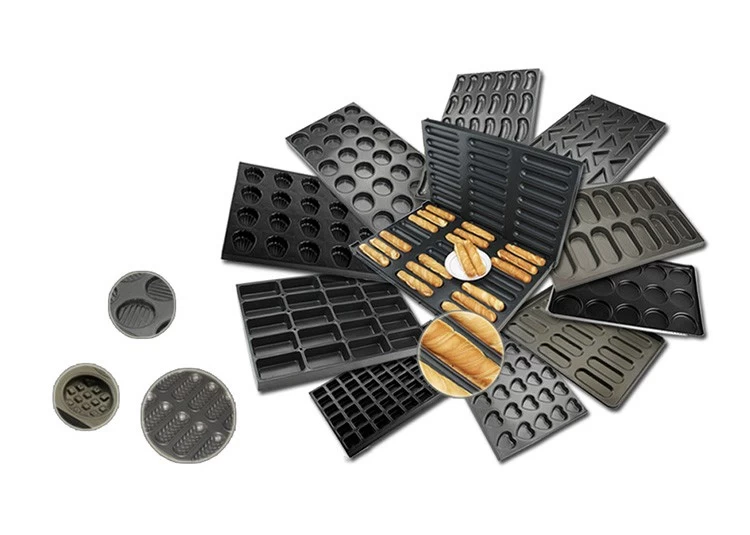

b. Pan Configuration

The configuration of a commercial croissant pan should align with your specific production requirements to maximize baking efficiency and output capacity. Key aspects to consider include:

- Number of Molds per Tray – Options range from 12 to 60 molds per tray, depending on croissant size and production volume.

- Mold Shape and Style – Choose from classic crescent shapes, mini croissants, or straight-rolled formats to suit your product line.

- Tray Dimensions – Available in standard sizes or customized to fit your ovens, racks, or automated machinery for seamless integration into your production system.

Selecting the right configuration ensures smoother workflow, better space utilization, and consistent baking results.

c. Surface Treatment

Surface treatment plays a vital role in enhancing the pan’s performance and maintenance. Non-stick coatings or silicone glazes provide several benefits, including:

- Effortless product release, reducing the risk of damage to delicate croissants

- Reduced cleaning time, improving overall bakery efficiency

- Extended pan lifespan by protecting against wear and corrosion

It is essential that all coatings are food-grade and FDA-approved to ensure safety, hygiene, and compliance with food manufacturing standards.

d. Perforation Options

Perforated pans feature small holes that enhance airflow during baking, promoting even heat circulation and helping to achieve a crispier, golden crust—perfect for croissants that require a flaky exterior. Conversely, non-perforated pans are better suited for producing croissants with a softer, more tender crust. Choosing the right perforation style depends on your desired product texture and baking method.

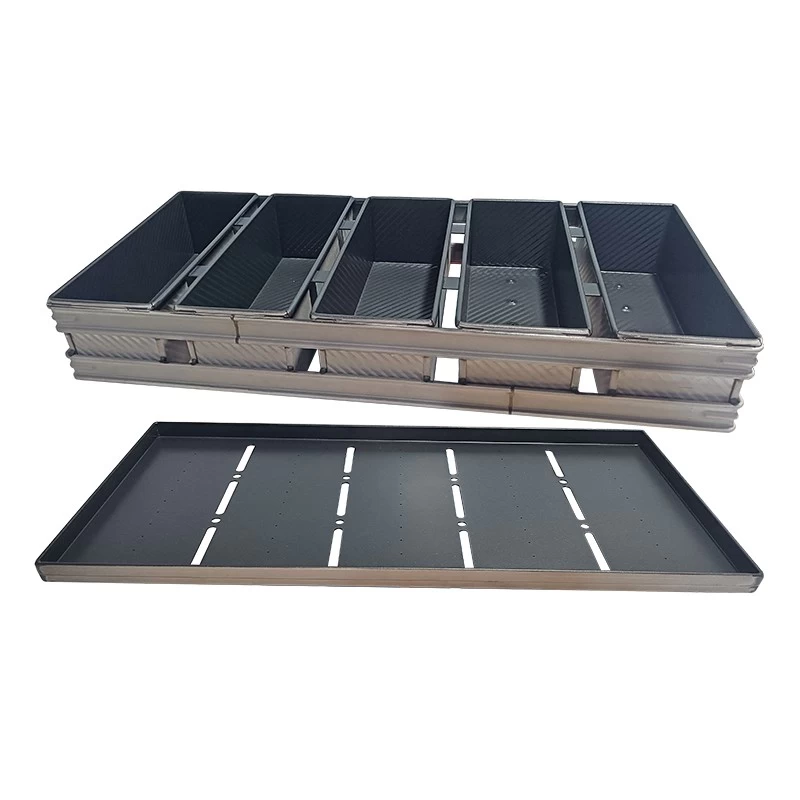

3. Compatibility with Industrial Production Systems

In commercial and industrial baking environments, your croissant pans must seamlessly integrate with existing machinery and workflows. Consider these factors to ensure smooth operation:

- Exact dimensions and design to fit conveyor belts, rack systems, and oven interiors without modification

- Stackability for efficient storage and transportation between production stages

- Durable yet lightweight construction to withstand frequent handling without causing operator fatigue

- Ergonomic features such as reinforced edges or handles that facilitate easy loading and unloading

Selecting pans designed with industrial compatibility in mind minimizes downtime and boosts overall production efficiency.

Standard pans don’t always meet the diverse needs of modern food production. Customization ensures that the pan:

- Matches your production system

- Aligns with your specific croissant size and style

- Carries your brand identity through logo engraving or design

Customization also allows flexibility in:

- Pan shape and depth

- Mold layout and spacing

- Material thickness and coating type

When your croissant production depends on precision, custom-made pans provide the reliability and performance standard pans can't.

5. Tsingbuy: Your Reliable Manufacturer for Custom Commercial Croissant Pans

With nearly two decades of experience, Tsingbuy stands as a leading manufacturer of professional commercial bakeware. Specializing in ODM & OEM services, Tsingbuy works closely with bakeries, food factories, and global distributors to deliver custom croissant pans built for high-volume production.

Why Choose Tsingbuy?

- End-to-end custom service: From hand sketches to 3D modeling, sample confirmation, and mass production

- Premium materials and coatings: Built for durability and baking perfection

- Customization to match automatic machinery systems: Precision sizing for tunnel ovens, conveyors, and rack setups

- Global support: Fast response and reliable international shipping

Whether you need a standard tray with professional quality or a uniquely tailored solution, Tsingbuy croissant pan factory in China helps optimize your baking process from design to delivery.

6. Conclusion: Get the Perfect Fit for Your Production Line

When consistency, efficiency, and performance are critical to your croissant production, choosing the right commercial croissant pan is more than a matter of preference — it's a strategic decision. From material and configuration to surface coating and automation compatibility, every detail counts.

Tsingbuy China bread baking tray supplier provides custom commercial croissant pans tailored to your operation’s unique needs. With professional support, premium materials, and decades of experience, we help food manufacturers and bakeries worldwide achieve perfect baking results — batch after batch.