What is a Commercial Madeleine Pan?

Contents:

2. Materials and Construction of Madeleine Pans

3. Commercial-grade Madeleine Pans

4. Customization Options from Tsingbuy

5. Tips for Choosing the Right Madeleine Pan

6. Where to Get Commercial Madeleine Pan

Madeleines are delicate, shell-shaped sponge cakes that originated in France and have become a beloved treat in bakeries around the world. Their signature ridged pattern and gently domed top come not from the batter alone, but from the unique pan used to bake them — the madeleine pan. While these pans are commonly found in home kitchens, commercial bakeries and food production facilities require madeleine pans designed for high efficiency, durability, and consistent results.

For professional bakers and industrial-scale producers, using a commercial-grade madeleine pan ensures uniform shape, perfect release, and optimal baking performance. Whether producing madeleines in bulk or integrating into automated baking systems, having the right bakeware is essential. That’s where Tsingbuy commercial baking pans manufactruer in China comes in — offering not only a wide selection of standard madeleine trays, but also customization services to meet the unique needs of commercial clients worldwide.

A madeleine pan is a specialized baking tray designed specifically for making madeleines — small, scallop-shaped sponge cakes that are crisp on the outside and tender within. The defining feature of a madeleine pan is its series of shell-like cavities, each molded to give the cakes their iconic ridged backs and elegant appearance.

These pans are typically made from aluminum, carbon steel, or aluminized steel, materials chosen for their excellent heat conductivity and baking performance. Depending on the application, they may feature a non-stick coating for easy demolding and quick cleanup.

Madeleine pans come in a variety of sizes and configurations. While a standard home-use pan may include 6 or 12 cavities, commercial madeleine pans often have 20, 24, or more cavities to accommodate large-scale baking in food factories or bakeries. Some industrial versions are designed as multi-mold trays that fit seamlessly into automatic machinery production systems.

In short, the madeleine pan is more than a baking tool — it's the key to achieving the distinctive look and texture of this classic French pastry, whether in a home kitchen or a high-output commercial bakery.

2. Materials and Construction of Madeleine Pans

The performance and longevity of a madeleine pan are largely determined by its material and structural design, especially in commercial baking environments where durability and efficiency are essential.

Common Materials:

- Aluminized Steel: Popular in commercial-grade bakeware for its strength and resistance to warping under high heat. It offers excellent thermal conductivity and corrosion resistance, making it ideal for continuous use in professional kitchens.

- Aluminum: Lightweight and known for its superior heat conduction, aluminum pans ensure even baking and browning. They are especially favored for their responsiveness to temperature changes and lightweight handling during production.

- Carbon Steel: Heavier and more robust, carbon steel retains heat well and is valued for creating crisp edges. However, it typically requires a protective coating to prevent rust. Carbon steel material is often preferred by home kitchen environments.

Surface Coating Options:

To improve functionality, many madeleine pans are finished with a non-stick coating — either PTFE-based or silicone — that allows for easy release of the delicate sponge cakes without damaging their iconic ridges. Non-stick coatings also reduce the need for greasing, contributing to cleaner production and time savings.

Structural Design:

Commercial madeleine pans are often built with reinforced frames or rolled edges to maintain shape and stability during repeated baking cycles. Pans designed for industrial production may be part of multi-mold tray systems, engineered to fit seamlessly with conveyor ovens and automated machinery. Proper pan construction ensures uniform cavity depth, consistent shape, and even heat distribution — all crucial for producing high-quality madeleines in bulk.

With the right materials and thoughtful construction, a madeleine pan becomes a reliable tool that delivers both visual appeal and baking precision, batch after batch.

3. Commercial-Grade Madeleine Pans

While home bakers may use a basic pan for occasional treats, commercial-grade madeleine pans are built to meet the demands of professional bakeries, food factories, hotel kitchens, and pastry production lines. These pans are designed for high-volume output, consistent quality, and seamless integration into automated baking systems.

Key Features of Commercial Madeleine Pans:

- High Cavity Count: Commercial pans often feature 20, 24, or even more cavities per tray, allowing for the efficient production of large batches in a single bake cycle.

- Heavy-Duty Construction: Made with aluminized steel or hard-tempered aluminum, these pans resist warping and maintain their form under continuous use and high heat conditions.

- Excellent Heat Distribution: Industrial pans are engineered for even heating across all cavities, ensuring uniform color, rise, and texture in every madeleine.

- Non-Stick Coating for Efficiency: Durable non-stick surfaces reduce the need for manual greasing, lower the risk of product damage, and simplify cleaning — all critical for maintaining hygiene and production speed.

- Compatibility with Machinery: Designed to match automatic conveyor systems and machinery production lines, these pans streamline production and minimize labor, making them ideal for commercial-scale operations.

Professional bakers understand that the right bakeware is not just about appearance — it directly impacts productivity and product quality. A well-constructed commercial madeleine pan helps maintain baking precision while supporting high-efficiency workflows in busy kitchens and industrial environments.

4. Customization Options from Tsingbuy

When it comes to large-scale or specialized baking operations, standard pans may not meet every need. That’s why China madeleine pans factory, Tsingbuy, offers customization services tailored to the unique requirements of commercial bakeries and food production facilities worldwide.

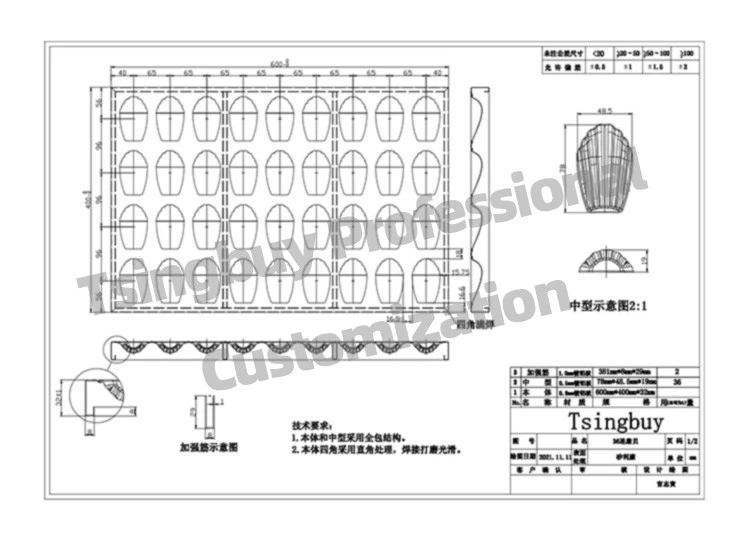

With nearly 20 years of manufacturing experience, Tsingbuy bakeware manufacturer in China specializes in custom-made commercial baking trays, including madeleine pans, designed to support both manual and fully automated production lines.

What Can Be Customized?

- Cavity Shape and Size: From classic shell shapes to custom molds with specific depths or curvature, cavity designs can be tailored for brand identity or special recipes.

- Tray Dimensions and Layout: Whether you need a compact pan for smaller ovens or a large, multi-cavity industrial tray, dimensions can be adapted to match your equipment and output targets.

- Materials and Coatings: Choose from aluminized steel, aluminum, or carbon steel, and opt for non-stick coatings such as PTFE or silicone to match your production needs.

- Reinforcement and Structure: Add features like reinforced frames, edge folding, or stacking compatibility for better durability and handling in fast-paced environments.

- Machinery Adaptation: Tsingbuy can produce pans that are fully compatible with conveyor systems, tunnel ovens, and automated baking lines, ensuring seamless integration into existing workflows.

End-to-End Service Process

Tsingbuy’s customization process includes concept development, technical drawing, sample confirmation, and bulk manufacturing — all managed with professional service and responsive communication. ODM and OEM projects are highly welcomed, with close collaboration at every stage to ensure the product meets both technical specifications and baking goals. Whether you're a large-scale food manufacturer or a commercial bakery chain, Tsingbuy madeleine baking trays supplier in China helps turn your specific requirements into efficient, high-performing madeleine pans built for consistency, speed, and quality.

5. Tips for Choosing the Right Madeleine Pan

Selecting the right madeleine pan is essential for achieving perfect results — whether you’re a boutique bakery or a high-capacity food production facility. From material to mold design, the pan you choose directly affects the texture, appearance, and efficiency of your baking process. Here are some key tips to help you make the right decision:

- Define Your Production Scale

Home or small-batch baking may only require standard pans with 6 to 12 cavities.

For commercial or industrial production, choose multi-cavity trays (20–30+ cavities) that boost output and reduce cycle time.

- Choose the Right Material

Aluminized steel is ideal for commercial use due to its strength, heat resistance, and longevity.

Aluminum provides excellent heat conduction and lightweight handling.

For high-end performance, always consider pans with reinforced edges or welded frames to withstand frequent use.

- Consider Surface Coating

Non-stick coatings (PTFE or silicone) are essential for quick release, maintaining shape, and reducing cleanup time.

Choose food-safe coatings rated for high-temperature baking and repeated use.

- Match Pan Size to Your Equipment

Ensure the tray dimensions are compatible with your deck ovens, rotary ovens, or automated machinery systems.

For automated lines, consider pans with features like standardized handles or interlocking edges for smooth mechanical handling.

- Evaluate Customization Needs

If standard sizes or shapes don’t meet your exact needs, consider customized madeleine pans from a manufacturer like Tsingbuy, who can tailor the pan’s cavity shape, tray layout, and materials to match your brand and baking process.

- Think About Long-Term Value

A quality madeleine pan is an investment. Opt for commercial-grade construction that ensures consistency, durability, and safety over time, even with continuous daily use.

By carefully considering these factors, bakeries can choose pans that not only enhance baking results but also improve workflow, reduce waste, and support consistent product quality.

6. Where to Get Commercial Madeleine Pans?

When it comes to sourcing reliable, commercial-grade madeleine pans, quality, customization capability, and manufacturer experience are key factors to consider. For professional bakeries, food factories, or baking equipment distributors, partnering with a trusted supplier ensures long-term value and consistent production results.

Tsingbuy Bakeware Manufacturer is a leading name in the commercial bakeware industry, with nearly two decades of experience producing high-performance commercial baking pans for clients around the world. Our madeleine pans are crafted from premium materials like aluminized steel and aluminum, and designed to meet the demands of high-output environments.

What sets Tsingbuy apart is their strong customization service. Whether you need a madeleine pan that fits a specific oven size, integrates with your automated baking line, or features a unique cavity design, Tsingbuy can develop and deliver a tailored solution through our ODM & OEM services — from technical drawing to sample development and full-scale production.

With a commitment to quality, functionality, and customer satisfaction, Tsingbuy is not only a supplier but a long-term partner for your professional baking needs. If you’re looking for dependable madeleine pans that support efficiency, consistency, and customization, Tsingbuy is the manufacturer to turn to.

The madeleine pan may seem like a simple tool, but it plays a crucial role in creating the iconic shape, texture, and quality of this beloved French pastry — especially in professional baking settings. From selecting the right material and coating to ensuring compatibility with machinery, the right pan makes all the difference in both product consistency and production efficiency.

For commercial bakeries and food manufacturers, investing in commercial-grade madeleine pans is essential for achieving reliable results at scale. And when off-the-shelf options fall short, Tsingbuy Bakeware Manufacturer stands ready with custom solutions, advanced design support, and years of industry expertise to help you bring your ideal bakeware to life.

Whether you’re expanding your production line or launching a new madeleine product, Tsingbuy offers the quality, flexibility, and service to support your growth — one perfect batch at a time.