How to Find the Perfect Custom Muffin Pans for Commercial Use?

MAIN CONTENTS

1. Material Selection: Durability Meets Perforamance

2. Cup Size and Tray Configuration

4. Compatibility with Machinery Production System

5. Customization Feature to Maximize Functionality

6. Professional DM&OEM Sevices and Food Safety Assurance

7. Choosing the Right Supplier: More Than Just the Product

8. Conclusion: Your Perfect Custom Muffin Pan Starts with Tsingbuy

In high-volume commercial baking, the right equipment is not just helpful—it’s critical to success. Among essential tools, muffin pans are used daily in large-scale bakeries, food factories, and central kitchens, where consistency and output matter most. Standard options may fall short in demanding environments, which is why custom muffin pans designed to match your specific production requirements can dramatically enhance efficiency, product uniformity, and overall workflow.

So, how do you find the ideal custom muffin pans for commercial use? This guide walks you through the key considerations—from material selection and surface treatment to pan configuration and manufacturer expertise—to help you make an informed decision for your professional bakery operation.

1. Material Selection: Durability Meets Performance

The choice of material is a foundational aspect when designing custom muffin pans for commercial use. It directly affects heat conductivity, structural integrity, corrosion resistance, and long-term performance under high-volume conditions. The most commonly used materials include:

Aluminum: Renowned for its excellent thermal conductivity, aluminum distributes heat evenly across the pan, ensuring uniform browning and consistent baking results. Its lightweight nature makes it easy to handle in fast-paced commercial environments. Aluminum is ideal for producing soft, airy muffins with delicate textures.

- Aluminized Steel: A widely preferred option in commercial bakeries, aluminized steel offers the best of both worlds—the heat transfer efficiency of aluminum and the structural strength of steel. It resists warping and deformation under high temperatures and frequent use, making it a reliable choice for automated and high-capacity baking systems.

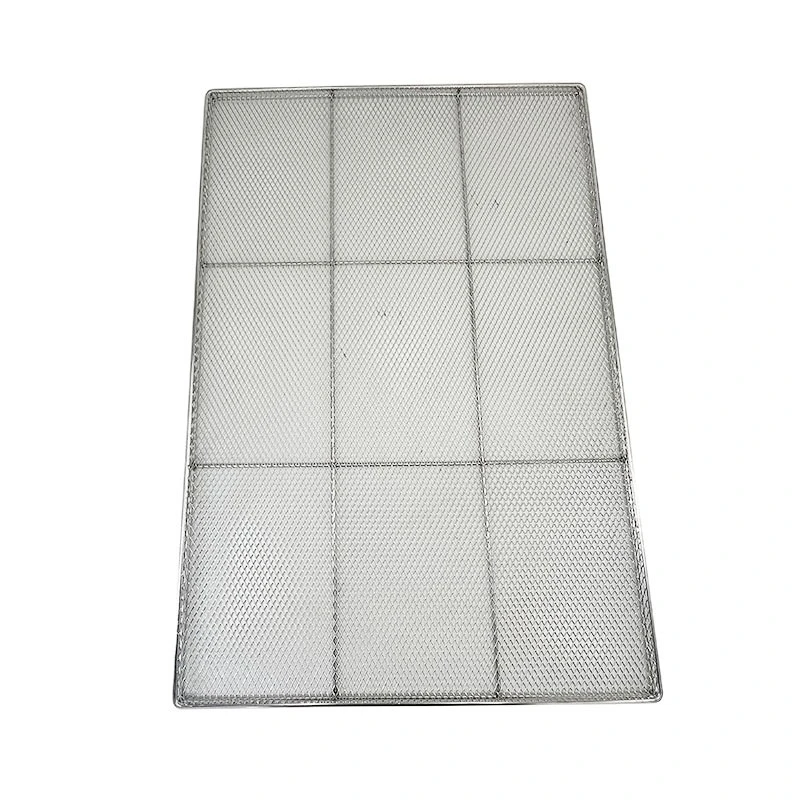

- Stainless Steel: It is valued for its superior strength, corrosion resistance, and long service life, making it suitable for demanding commercial environments and heavy-duty baking applications. However, it has relatively low thermal conductivity compared to aluminum and aluminized steel, which can affect heat distribution during baking. To enhance performance, stainless steel pans are often coated with non-stick or silicone finishes. It's important to note that stainless steel is among the most expensive material options, reflecting its durability and premium quality—best suited for bakeries prioritizing long-term reliability.

- Carbon Steel: It offers decent heat conduction and is lower in cost, making it a popular choice for home kitchens or light-duty use. However, it lacks the durability and corrosion resistance required for continuous, high-volume commercial baking. Without proper coating and maintenance, carbon steel pans are prone to deform, making them less ideal for professional bakery operations.

When selecting the right material, it’s important to align with your operational needs—such as baking temperature range, muffin characteristics (texture, size), and maintenance requirements. A well-chosen material ensures optimal baking results, reduces production downtime, and extends the service life of your muffin pans.

2. Cup Size and Tray Configuration

Commercial muffin pans come in a variety of configurations—typically 6, 12, 24, or more cups per tray—but for industrial-scale bakeries and food factories, custom configurations are often essential to align with specific product requirements and equipment constraints.

Key considerations include:

- Cup Diameter and Depth: The size and volume of each cavity should be tailored to your product specifications, whether you're baking mini muffins, standard sizes, or oversized formats. Accurate sizing ensures portion control and visual consistency.

- Uniformity: Consistent cup dimensions across the entire tray are crucial for even baking, standardized weight, and predictable results—especially when operating on automated production lines.

- Spacing: Proper spacing between cups promotes efficient heat circulation and uniform browning, while also optimizing tray size for compatibility with ovens, conveyors, and packaging systems.

As a leading muffin pan factory in China since 2006, Tsingbuy offers full customization of cup size, depth, layout, and total cavity count. Whether you require unique dimensions, multi-row designs, or machinery-adapted trays, Tsingbuy delivers solutions tailored to your commercial bakery’s operational demands.

3. Surface Coating Options

The surface treatment of your muffin pans plays a crucial role in product release, cleaning efficiency, and overall pan longevity. Choosing the right coating depends on your production scale, product type, and sanitation protocols.

- Non-stick Coating (PTFE/Silicone): These coatings provide excellent release properties, minimizing sticking and reducing the need for greasing. They are ideal for high-throughput commercial muffin production where fast turnover and minimal cleaning downtime are essential. Non-stick coatings also help extend the pan's usable life when properly maintained.

- Uncoated Finish: Preferred by some commercial bakeries for its cost-effectiveness and resistance to coating wear under continuous use. Uncoated pans can be seasoned for a natural release effect and are well-suited for operations with rigorous cleaning processes or specific hygiene requirements.

Tsingbuy offers both coated and uncoated options and works closely with clients to determine the most suitable surface treatment based on application, cleaning procedures, and product type.

4. Compatibility with Machinery Production Systems: Engineered for Seamless Integration

For bakeries operating with automated or semi-automated equipment—such as rotary ovens, convection ovens, or continuous conveyor lines—muffin pans must be precisely engineered to integrate seamlessly with the machinery in use.

Key customization options include:

- Tray Size and Thickness: Dimensions should be tailored to fit your specific oven chambers or conveyor widths. Proper thickness ensures structural stability and resistance to warping under high temperatures and repeated cycling.

- Reinforced Frames and Curled Edges: Enhancements like reinforced edges or welded frames increase strength, extend pan life, and maintain shape under high-volume, high-heat conditions.

- Stackability and Handling Efficiency: Custom pans can be designed for easy stacking, smooth loading/unloading, and compatibility with robotic or manual handling systems, improving workflow and reducing labor.

With extensive experience serving global food factories and commercial bakeries, Tsingbuy non stick muffin pan manufacturer in China specializes in producing muffin pans that align with both standard and fully automated production systems, ensuring operational efficiency from oven to packaging.

5. Customization Features to Maximize Functionality

Today’s commercial bakeries demand more than off-the-shelf solutions. Functional enhancements and tailored designs can significantly improve productivity, product presentation, and handling efficiency. Tsingbuy offers a wide range of light to deep customization options to meet the unique requirements of professional baking operations.

- Custom branding: Add your logo through engraving or stamping to reinforce brand identity and prevent mix-ups in shared production spaces.

- Special cavity shapes: Choose from standard, mini, jumbo, or uniquely shaped cavities such as tulip-style or dome-top molds to suit specific product lines or seasonal offerings.

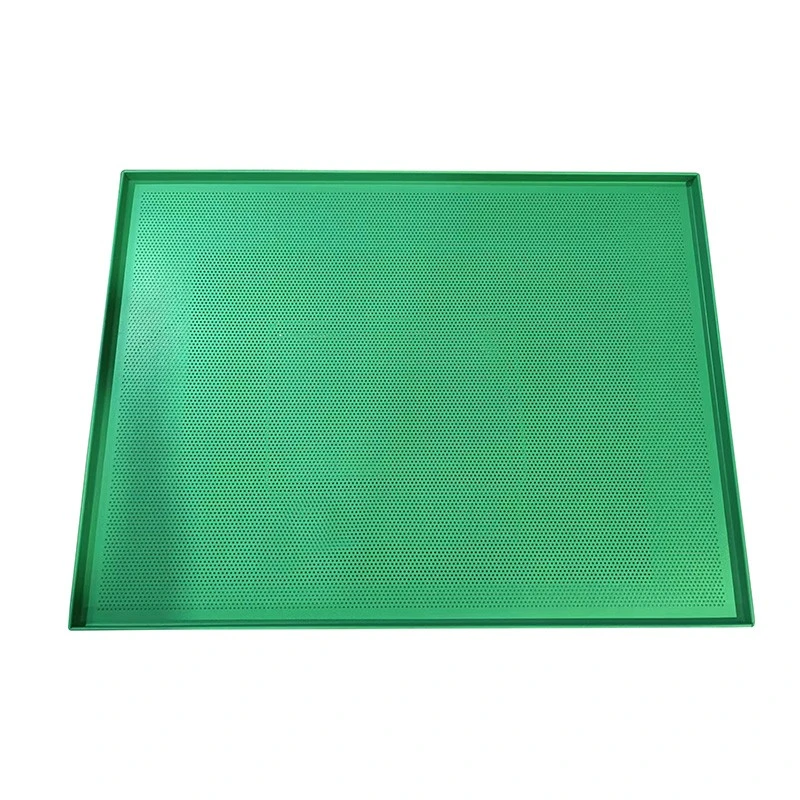

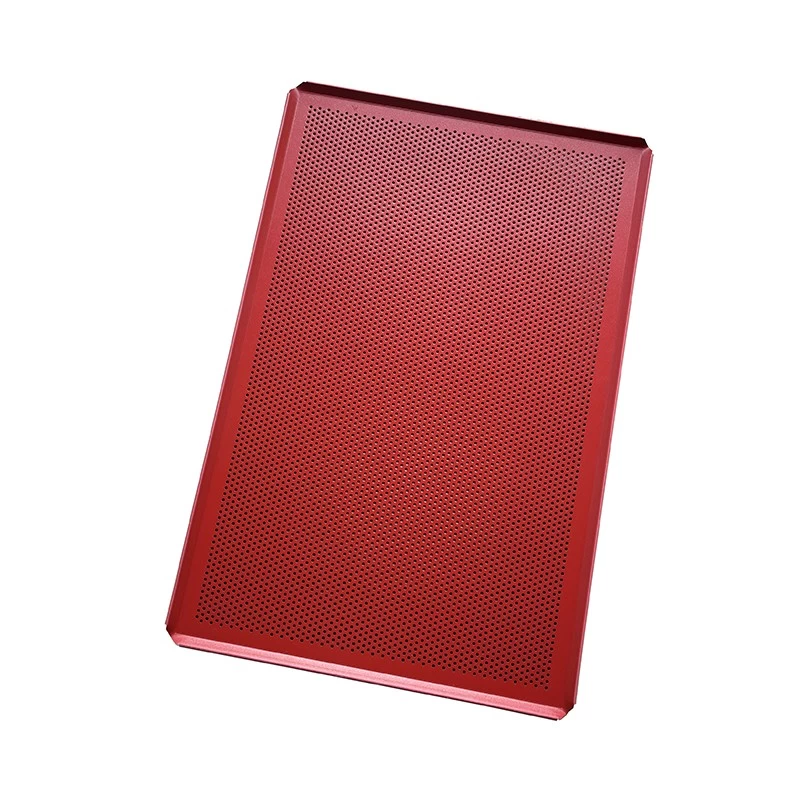

- Perforated bottoms: Improve heat circulation and reduce baking time with perforated cavity bases—ideal for products that benefit from a crisp bottom texture.

- Ergonomic Additions: Integrate features like reinforced rims, added handles, or stackable frames to enhance structural durability and streamline handling in high-volume environments.

With advanced in-house design and tooling capabilities, Tsingbuy can turn your design concepts into precise, production-ready solutions—ensuring both functionality and performance for your commercial bakery.

6. Professional ODM & OEM Services and Food Safety Assurance

When sourcing custom muffin pans for commercial use, it’s essential to partner with a manufacturer that offers not only high-quality products but also comprehensive ODM & OEM services. Established in 2006, Tsingbuy has nearly two decades of experience delivering customized bakeware solutions to clients worldwide. Their services include in-depth consultations, technical drawing support, rapid prototyping, sampling, and full-scale production—all backed by strict quality control and flexible minimum order quantities. Whether you're developing a new product or adapting bakeware for existing machinery, Tsingbuy’s expert project team ensures that every solution is tailored to meet your operational and branding goals.

Equally important is compliance with international food safety standards. For any bakeware used in food production, confirming the use of food-grade materials and coatings is non-negotiable. Tsingbuy guarantees that all custom muffin pans conform to recognized food safety certifications, providing global clients with confidence in both safety and regulatory compliance.

7. Choosing the Right Supplier: More Than Just the Product

Selecting the right supplier for custom muffin pans involves more than comparing specifications. A reliable partner should offer deep industry knowledge, proven experience, and responsive support. Key points to evaluate include:

- Experience with Commercial Clients: Look for a supplier with a solid track record in serving professional bakeries, food factories, or equipment integrators.

- Project References and Samples: Request examples or case studies from similar projects to assess product quality and customization capabilities.

- Ongoing Technical Support: Ensure the supplier provides continuous support, from design consultation to post-delivery assistance, with flexibility for future adjustments.

As one of China’s leading bakeware manufacturers, Tsingbuy muffin baking tray supplier in China has delivered customized muffin trays and commercial baking solutions to thousands of clients around the globe. From international bakery chains to industrial production lines, Tsingbuy is trusted for its high-quality craftsmanship, responsive service, and expertise in developing bakeware tailored to complex commercial needs.

Conclusion: Your Perfect Custom Muffin Pan Starts with the Right Partner

Choosing the perfect custom muffin pan goes far beyond selecting dimensions—it’s about aligning every detail with your production goals, from material selection and surface coating to equipment compatibility and brand identity. A well-designed pan enhances efficiency, consistency, and product quality on a commercial scale.

With nearly two decades of experience, Tsingbuy Bakeware Manufacturer stands out as a trusted partner for professional bakeries and food factories worldwide. Offering comprehensive ODM & OEM services, advanced customization capabilities, and an unwavering commitment to quality, Tsingbuy transforms your requirements into high-performance, tailor-made muffin pans built to excel in demanding commercial environments.