Perforated vs. Solid Loaf Pans: When to Use Each

Contents

- What Are Solid Loaf Pans?

- What Are Perforated Loaf Pans?

- Key Diffences Between Perfroated and Solid Loaf Pans

- When to Use Solid Loaf Pans

- When to Use Perforated Loaf Pans

- Considerations for Industrial and Commercial Bakeries

- Tsingbuy: Expertise in Custom Loaf Pan Solutions

- Conclusion

Loaf pans are a fundamental tool in both commercial bakeries and industrial baking facilities. From sandwich loaves and brioche to rustic artisan breads, the shape and texture of the final product are heavily influenced by the type of pan used. Whether a bakery operates on a small batch basis or integrates a fully automated production line, selecting the right loaf pan is essential for achieving consistent results and optimizing baking performance.

One often-overlooked yet critical distinction in loaf pan design is whether the pan is perforated or solid. This subtle difference has a significant impact on the crust development, moisture retention, and overall texture of the baked bread. Perforated pans allow greater airflow and are ideal for crispier crusts, while solid pans are better suited for softer, uniform loaves.

In this article, we’ll explore the characteristics, advantages, and best-use scenarios for perforated vs. solid loaf pans, helping commercial bakeries and food manufacturers choose the most suitable option for their products and production environments.

1. What Are Solid Loaf Pans?

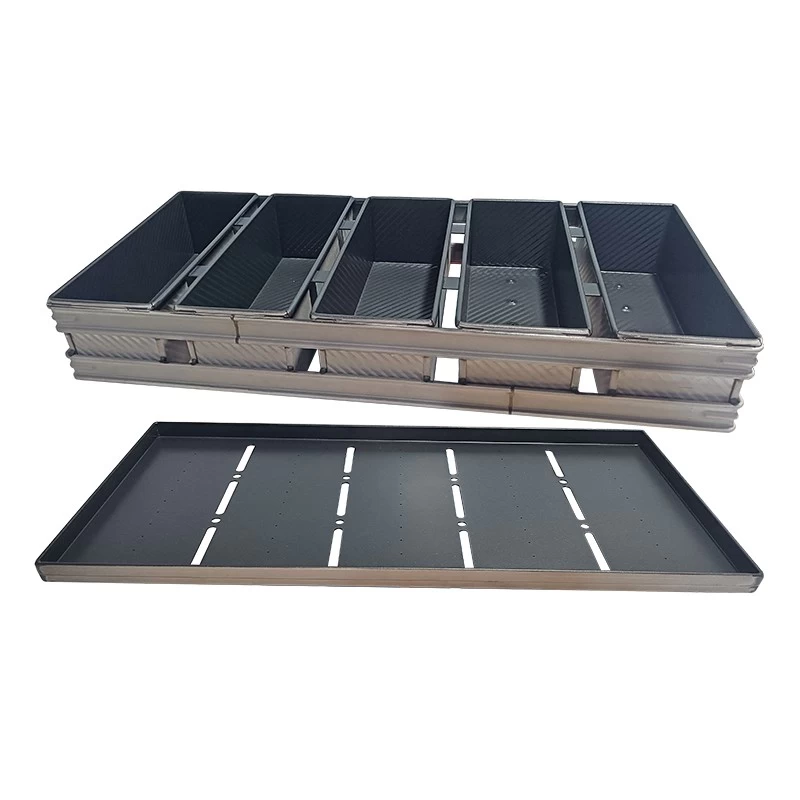

Solid loaf pans are the traditional choice for a wide range of bread and cake products. These pans are constructed with a sealed, non-perforated surface, which means there are no holes in the pan. This closed design helps retain moisture during baking, resulting in a softer crust and more uniform crumb texture.

Solid loaf pans are typically made from aluminum, aluminized steel, or stainless steel, offering excellent durability and heat conductivity. Aluminum pans, in particular, are popular in commercial baking for their lightweight structure and even heat distribution. Many models come with non-stick coatings or anodized finishes to improve release and cleaning efficiency.

● Solid Pans with Holes at the Bottom

A popular variation of the solid loaf pan includes a limited number of holes at the bottom only, while the sides remain completely closed. These pans offer a balance between traditional solid pans and fully perforated models. The bottom perforation improves heat penetration and helps create a slightly firmer bottom crust, while the closed sidewalls preserve the loaf’s softness and shape.

This hybrid design is especially suitable for commercial sandwich loaves and medium-density breads that benefit from enhanced base browning without compromising the overall moisture content.

● Application

Thanks to their design, solid pans ensure a more controlled bake by limiting direct airflow to the dough, which reduces the risk of over-drying or over-browning. They are ideal for high-volume production where consistency and softness are priorities.

Common applications for solid loaf pans include:

- Classic sandwich bread

- Brioche and milk bread

- Pound cakes and quick breads

- Enriched or high-hydration doughs

In commercial bakery settings, solid loaf pans—especially those in strap configurations—are widely used on automatic machinery lines to produce uniform loaves at scale.

2. What Are Perforated Loaf Pans?

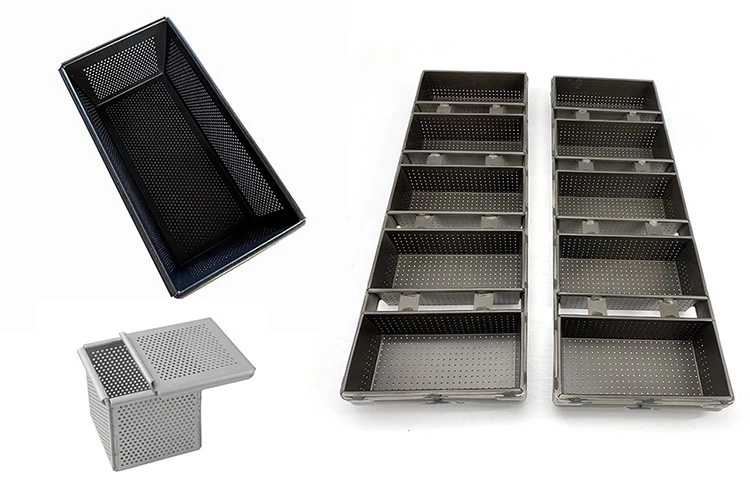

Perforated loaf pans are specifically engineered for baking breads that require a crustier texture and drier finish. These pans are fully perforated across all surfaces—including the bottom, sidewalls, and even ends—with a dense, uniform pattern of small holes. This design maximizes airflow and allows steam to escape efficiently during baking, which helps develop a crispy, golden crust and a more structured exterior.

The even perforation ensures consistent heat distribution around the entire loaf, speeding up baking time while enhancing crust formation. This makes perforated pans a top choice for artisan-style breads that benefit from a caramelized exterior and well-defined shape.

These pans are usually crafted from aluminum or aluminized steel, known for their lightweight, excellent heat conductivity, and strength. Many models are also treated with food-safe non-stick or silicone coatings to ensure easy release and cleaning, especially under high-volume use.

● Key Features of Fully Perforated Loaf Pans:

- Evenly spaced small holes on all surfaces (bottom, sides, ends)

- Enhanced airflow and moisture release during baking

- Ideal for use in convection ovens, deck ovens, or steam-injected systems

- Often used in artisan bakeries or specialty production lines

● Best Suited For:

- Crusty artisan loaves (e.g., sourdough, rustic bread)

- Whole grain or rye breads requiring dry heat

- Specialty breads with an open crumb and firm crust

- Bakeries that prioritize crust texture and visual appeal

Perforated loaf pans are an excellent solution for bakers looking to elevate crust quality and accelerate baking performance. They are also compatible with commercial production systems and can be customized into strap configurations for machinery-based operations.

3. Key Differences Between Perforated and Solid Loaf Pans

Choosing between solid and perforated loaf pans depends largely on your desired crust texture, dough type, and baking setup. Below is a side-by-side comparison of their key features and functional differences to help guide your selection:

| Feature |

Solid Loaf Pans |

Perforated Loaf Pans |

|

Surface Design |

Sealed surface; no holes or only a few holes at the bottom |

Fully perforated on all sides and bottom with small, evenly spaced holes |

|

Airflow & Steam Release |

Limited airflow; higher moisture retention |

Enhanced airflow; effective steam escape |

|

Crust Texture |

Soft and uniform |

Crispy, caramelized, and well-browned |

|

Crumb Structure |

Tender, moist crumb |

Firmer crumb with more structure |

|

Heat Penetration |

Slower, more even |

Faster, more direct and responsive |

|

Ideal Dough Types |

Enriched doughs, high hydration, sweet breads |

Lean doughs, rustic breads, sourdough |

|

Best Applications |

Sandwich loaves, brioche, pound cake |

Artisan breads, whole grain loaves |

|

Use in Production Systems |

Ideal for automatic lines; excellent shape retention |

Suitable for artisan-style or crust-focused lines |

|

Cleaning & Maintenance |

Easier to clean due to solid surface |

Requires more attention during cleaning due to perforations |

This comparison highlights how each type of pan offers its own advantages depending on baking goals. In the next sections, we'll take a closer look at when to use each type in commercial or industrial baking environments.

4. When to Use Solid Loaf Pans

Solid loaf pans—whether fully sealed or designed with a few holes at the bottom—are the preferred choice for producing breads that require moisture retention, soft crusts, and a uniform crumb. These pans create a more enclosed baking environment, which slows moisture evaporation and promotes even, gentle baking. As a result, they are ideal for a wide range of commercial products where softness, shape control, and volume consistency are critical.

● Ideal Scenarios for Solid Loaf Pans:

Soft Sandwich Breads:

The sealed structure of solid pans supports the rise and structure of soft, fluffy sandwich loaves, helping achieve a smooth crust and tender interior that’s easy to slice.

Enriched Doughs:

Breads with high sugar, fat, or dairy content—such as brioche, milk bread, and challah—bake best in solid pans that help preserve internal moisture and prevent over-browning.

Cakes and Quick Breads:

Solid loaf pans are essential for pound cakes, banana bread, and other batter-based products where even baking and shape stability are crucial.

High-Volume, Automated Production:

In industrial food factories, solid pans (especially in strap form) offer excellent shape retention, uniform baking, and mechanical compatibility with automatic depanners, conveyors, and ovens.

Controlled Bottom Crust (Pans with Bottom Holes):

For bakeries seeking a slightly firmer base without compromising side softness, solid pans with a few small holes at the bottom offer a balanced solution. This design enhances base browning while maintaining gentle top and side baking.

● Recommended For:

- Commercial sandwich bread lines

- Industrial food factories with high-speed machinery

- Bakeries producing high-hydration or enriched doughs

- Any product where softness, volume, and consistency are priorities

In short, solid loaf pans remain the go-to option for classic bread styles and mass production environments, offering reliability, versatility, and ease of use across a wide variety of bakery operations.

5. When to Use Perforated Loaf Pans

Perforated loaf pans, fully perforated with small, evenly spaced holes on all sides and the bottom, are specially designed to create breads with a crisp, well-browned crust and a structured crumb. Their enhanced airflow and moisture escape capabilities make them ideal for baking styles that emphasize texture and appearance, particularly in artisan and specialty bread production.

● Ideal Scenarios for Perforated Loaf Pans:

Crusty Artisan Breads:

Perforated pans excel at producing breads like sourdough, rustic rye, and whole grain loaves, where a firm, crackly crust is a defining characteristic.

Lean Doughs:

Breads made from low-fat, low-sugar doughs benefit from the drier baking environment created by perforated pans, which helps develop a golden, crunchy exterior.

Convection and Deck Oven Baking:

These pans work especially well in ovens with strong airflow or steam injection, where the perforations facilitate even heat distribution and moisture release, ensuring consistent results.

Specialty and Small-Batch Bakeries:

Artisan bakeries focused on product quality, crust texture, and visual appeal often prefer perforated pans to achieve signature crust characteristics that set their breads apart.

Enhanced Baking Efficiency:

The improved heat transfer speeds up baking times, making perforated pans suitable for operations that require faster throughput without compromising quality.

● Recommended For:

- Artisan and specialty bread producers

- Bakeries using deck, convection, or steam ovens

- Recipes emphasizing crust texture and open crumb structure

- Commercial lines prioritizing crust development and baking speed

In summary, perforated loaf pans are the preferred choice when the goal is to achieve superior crust quality, faster baking times, and enhanced visual appeal—making them indispensable for artisan and specialty bakery operations.

6. Considerations for Industrial and Commercial Bakeries

Selecting the right loaf pan for your bakery goes beyond crust and crumb preferences—it must also align with your production environment, equipment, and operational needs. Here are key factors recommended by Tsingbuy China commercial bakeware supplier that commercial and industrial bakeries should consider when choosing between solid and perforated loaf pans:

● Production Line Compatibility

Solid Loaf Pans:

Commonly used in high-speed automated lines, solid pans—especially strap sets—offer excellent shape retention and uniformity. They are compatible with depanners, conveyors, and automatic loading systems, ensuring efficient workflow.

Perforated Loaf Pans:

While also available in strap form, fully perforated pans are more often used in artisan or semi-automated lines where crust quality is prioritized. Their design is suitable for ovens with strong airflow, such as deck or convection ovens.

● Cleaning and Maintenance

Solid Pans:

Easier to clean due to the smooth, continuous surface. Less prone to trapping dough or crumbs, which minimizes downtime and reduces labor.

Perforated Pans:

Require more careful cleaning as the perforations can trap dough residue and flour. Regular maintenance is essential to preserve pan performance and prevent buildup.

● Material and Coating Options

Both pan types are commonly manufactured from aluminum or aluminized steel, valued for heat conductivity and durability. Non-stick or anodized coatings can be applied to improve food release and extend pan lifespan.

● Customization for Baking Systems

Pan Size and Shape:

Tailoring dimensions and strap configurations to fit specific machinery and baking trays improves efficiency.

Strap Designs:

Customized strap pans allow easy handling, stacking, and compatibility with automatic depanning and loading equipment.

Surface Treatments:

Specialized coatings (e.g., hard anodized, silicone non-stick) can be selected based on the baked product and cleaning protocols.

By carefully considering these factors, bakeries can select loaf pans that not only produce the desired bread quality but also integrate smoothly into their production processes, maximizing efficiency and product consistency.

7. Tsingbuy’s Expertise in Custom Loaf Pan Solutions

At Tsingbuy loaf pan manufacturer in China, we understand that every bakery has unique requirements—whether it’s achieving the perfect crust, optimizing for high-speed production, or matching the specifications of your bakery machinery. With nearly 20 years of experience, we specialize in delivering customized loaf pans tailored to your specific baking needs and operational demands.

● Comprehensive Product Range

Solid Loaf Pans:

Available in various sizes and strap configurations, our solid pans are designed for superior moisture retention and consistent loaf shape. Perfect for enriched doughs and high-volume sandwich bread production.

Fully Perforated Loaf Pans:

Engineered with uniformly distributed small holes on all sides and bottoms, our perforated pans provide enhanced airflow and crust development. Ideal for artisan breads and specialty loaves that require a crispy, well-browned crust.

● ODM & OEM Services

Tsingbuy offers flexible ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services, enabling bakeries and baking equipment manufacturers to:

Customize pan dimensions, hole size, and pattern density

Select materials such as aluminum or aluminized steel

Choose surface treatments including non-stick and anodized coatings

Design strap configurations optimized for your production line

● Compatibility with Machinery Production Systems

Our loaf pans are thoughtfully designed to integrate seamlessly with automatic production lines, depanning equipment, and industrial ovens. Whether you operate a bakery with manual processes or a fully automated system, Tsingbuy provides loaf pans engineered to boost efficiency and maintain consistent baking quality.

● Quality and Durability

We prioritize material quality, precision manufacturing, and rigorous quality control to ensure our pans withstand the demands of commercial baking environments. Our pans offer excellent heat conduction, durability, and easy cleaning—helping bakeries maintain productivity and reduce downtime.

By partnering with Tsingbuy, bakeries can confidently source loaf pans that elevate their baking results while supporting scalable, efficient production.

9. Conclusion

Choosing the right loaf pan is essential to achieving your bakery’s desired product quality and operational efficiency. Both solid and fully perforated loaf pans offer distinct advantages tailored to different baking needs—from the soft, tender crumb of enriched breads to the crisp, flavorful crust of artisan loaves.

Solid pans, including those with limited bottom perforations, are ideal for maintaining moisture and producing uniform, soft breads—making them the go-to option for high-volume sandwich and cake production. On the other hand, fully perforated pans enhance airflow and heat circulation, perfect for bakeries focused on crust development and rustic bread styles.

For commercial and industrial bakeries, factors such as production line compatibility, cleaning, and customization play a critical role in pan selection. With nearly two decades of expertise, Tsingbuy aluminum baking pans factory in China offers a comprehensive range of custom loaf pan solutions designed to meet these demands and help bakeries maximize baking performance.

Whether you’re scaling up production or refining product quality, selecting the appropriate loaf pan can make a significant difference. We invite you to explore Tsingbuy’s professional loaf pan offerings to find the perfect fit for your baking operation.