Why Anodized Aluminum Sheet Pans are Popular in Commercial Bakeries

Contents

- Superior Durability for Heavy-Duty Use

- Excellent Heat Conductivity for Consistent Results

- Non-Reactive Surface for Versatility

- Easy Maintenance and Cleaning

- Professional Appearance and Long-Lasting Finish

- Cost-Effective Investment Over Time

- Customization for Modern Bakeries

- Conclusion: Why Anodized Aluminum is the Smart Choice

In the fast-paced world of commercial baking, every detail matters—from the ingredients to the machinery and, importantly, the bakeware itself. Commercial sheet pans are among the most heavily used tools in professional kitchens and bakeries, and choosing the right material can have a direct impact on baking quality, efficiency, and cost-effectiveness. While traditional aluminum pans have long been an industry standard, more and more professional bakers are turning to the anodized aluminum sheet pan for its superior durability and performance.

So, what makes anodized aluminum such a popular choice in commercial bakeries? Tsingbuy commercial sheet pan manufacturer in China takes to explore the key advantages.

Superior Durability for Heavy-Duty Use

One of the greatest benefits of anodized aluminum pans is their strength. The anodizing process involves treating the surface of the aluminum with an electrochemical process that thickens and hardens its natural oxide layer. This results in a material that is significantly tougher than raw aluminum.

In a busy bakery where pans are constantly going in and out of hot ovens, durability is crucial. Regular pans without high quality may warp, dent, or scratch over time, but anodized aluminum pans are built to withstand high heat and rigorous handling. This makes them an ideal long-term investment for bakeries that rely on consistent performance from their bakeware.

Excellent Heat Conductivity for Consistent Results

Aluminum is already known for its superior heat conductivity, and anodized aluminum retains this property. A commercial sheet pan made from anodized aluminum distributes heat evenly across the surface, ensuring baked goods brown uniformly and bake consistently from edge to center.

For large-scale production where consistency is non-negotiable, this even heat distribution is invaluable. Whether it’s bread, pastries, cookies, or cakes, the results are reliable batch after batch. A poorly baked tray not only wastes ingredients but also disrupts workflow—something professional bakers cannot afford.

Non-Reactive Surface for Versatility

Unlike standard aluminum without surface treatment, which can react with acidic ingredients such as tomatoes, lemon juice, or vinegar, anodized aluminum has a non-reactive surface. This means it will not alter the taste, color, or appearance of baked goods.

For bakeries that produce a wide variety of products, from savory items to citrus-based pastries, this feature makes the anodized aluminum sheet pan a versatile and safe choice. It eliminates the risk of metallic flavors or unsightly discoloration, which could compromise product quality.

Easy Maintenance and Cleaning

Time is money in commercial bakeries, and every second spent scrubbing pans reduces efficiency. Anodized aluminum pans have a smoother, harder surface that resists sticking and is much easier to clean compared to untreated pans.

Staff can quickly wash, dry, and reuse them without worrying about stubborn stains or lingering residues. This not only improves hygiene but also reduces overall labor costs. For bakeries that go through hundreds of baking trays daily, this is a significant advantage.

Maintenance and Cleaning Tips for Anodized Aluminum Sheet Pans:

- Hand wash preferred: Use warm water and mild dish soap instead of harsh detergents or abrasive cleaners, which may damage the anodized surface.

- Avoid metal utensils: Use silicone, wood, or plastic tools to prevent scratches.

- Dry immediately: After washing, dry pans thoroughly with a soft cloth to avoid water spots.

- No dishwasher: Commercial dishwashers often use strong chemicals that can shorten the lifespan of anodized pans.

- Regular inspection: Check pans periodically for dents or deep scratches, and replace if they affect baking performance.

By following these simple steps, bakeries can extend the lifespan of their pans and keep them in top condition. A trusted anodized baking tray factory in China can also provide guidance on proper care and offer replacement options tailored to commercial production needs.

Professional Appearance and Long-Lasting Finish

Another reason anodized aluminum sheet pans are popular is their sleek, professional look. The anodizing process gives pans a darker, stain-resistant finish that looks clean even after years of use. Unlike raw aluminum, which can discolor or corrode, anodized pans maintain their attractive appearance for longer.

For bakeries with open kitchens or front-of-house displays, the presentation of equipment matters. Using anodized pans not only ensures better performance but also projects a polished, professional image to customers.

Cost-Effective Investment Over Time

While anodized pans may have a slightly higher initial cost compared to standard aluminum pans, they are more cost-effective in the long run. Their extended lifespan, resistance to damage, and reduced maintenance requirements mean bakeries replace them less often.

For professional kitchens where margins are tight and efficiency is key, investing in high-quality commercial sheet pans saves money over time. Instead of replacing warped or damaged pans every few months, bakeries can rely on anodized pans for years of heavy use.

Customization for Modern Bakeries

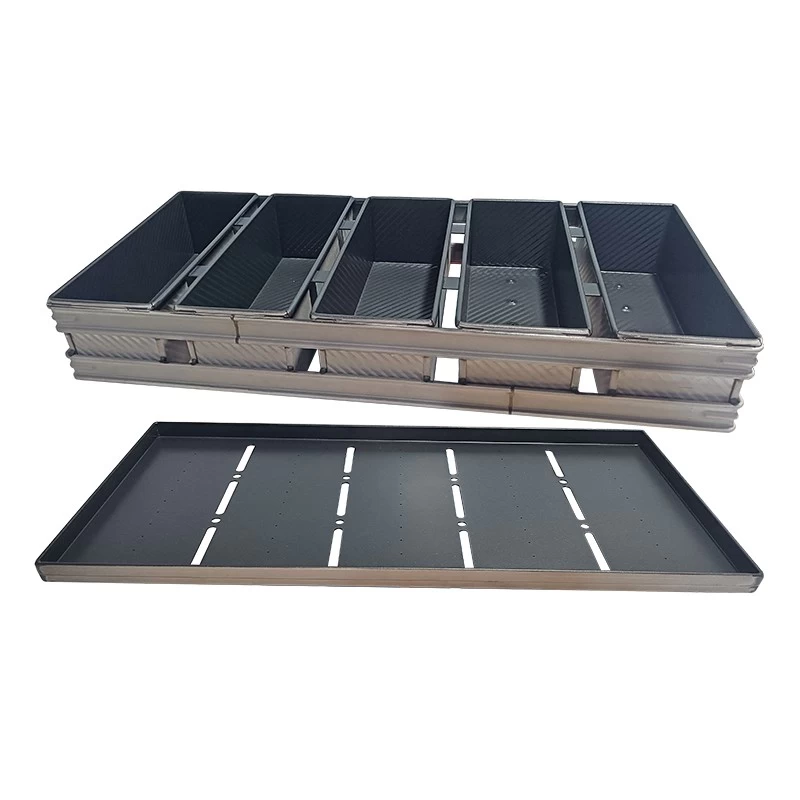

Another factor driving popularity is the ability to customize anodized pans. Many bakeries today operate with automatic machinery production systems, which require trays designed to exact specifications. A reliable custom bakery trays supplier can produce anodized aluminum pans in different sizes, thicknesses, and designs to fit both manual and automated production.

For example, bakeries may require pans with perforations for better airflow, reinforced edges for stacking, or specialized coatings for non-stick performance. Custom anodized sheet pans can be tailored to meet these unique production requirements, helping bakeries maximize output and maintain consistent quality.

Conclusion: Why Anodized Aluminum is the Smart Choice

From superior durability and excellent heat conductivity to easy cleaning and professional appearance, anodized aluminum sheet pans tick all the boxes for commercial bakeries. They meet the high demands of large-scale baking, reduce long-term costs, and deliver consistent results batch after batch.

For bakeries seeking efficiency, reliability, and versatility, investing in anodized aluminum bakeware is a smart decision. And with the added benefit of customization from a trusted custom bakery trays supplier in China, like Tsingbuy bakeware industry, bakeries can ensure their pans are perfectly matched to their production systems.

When performance and durability matter most, anodized aluminum stands out as the ultimate choice in commercial sheet pans—helping bakeries achieve flawless results every time.