Top 5 Features to Look for in a Commercial-Grade Baguette Pan

Contents

- Food-Grade Material with High Heat Resistance

- Perforated Design for Optimal Airflow

- Durable Non-Stick Surface Treatment

- Reinforced Structure for Long-Term Stability

- Customization for Commercial Ovens and Production Lines

- FAQ for Commercial & Industrial Buyers

In a professional bakery, restaurant kitchen, central kitchen, or industrial food factory, the quality of your baguette pan directly affects baking consistency, crust texture, production efficiency, and overall output. For Bakeware brands, distributors, commercial bakeries, restaurants, and food factory facilities, selecting the right commercial-grade baguette pan is not only about baking results, but also about durability, operational efficiency, standardization, and long-term cost control. A truly commercial-grade baguette pan is designed not only for excellent baking performance but also for long-term durability and compatibility with high-volume operations.

Whether you run an artisan bakery, a central kitchen, or an automated bread factory, here are the top 5 features to look for when choosing a commercial-grade baguette pan.

1.Food-Grade Material with High Heat Resistance

The foundation of any high-quality baguette pan is its material. Commercial bakeries typically rely on aluminum or aluminized steel due to their excellent heat conductivity and structural strength.

Key points to consider:

- Fast and even heat transfer to ensure uniform baking across all loaves

- Resistance to warping under continuous high-temperature baking cycles

- Food-grade, non-toxic materials that meet international safety standards

High-quality materials help achieve consistent oven spring and crust color while extending the service life of the pan in demanding commercial environments.

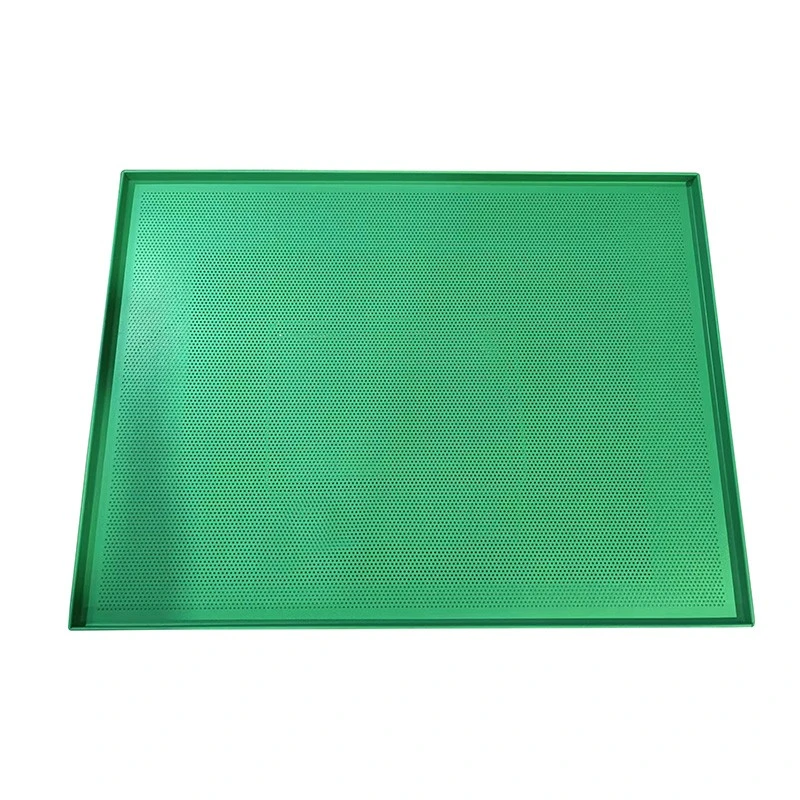

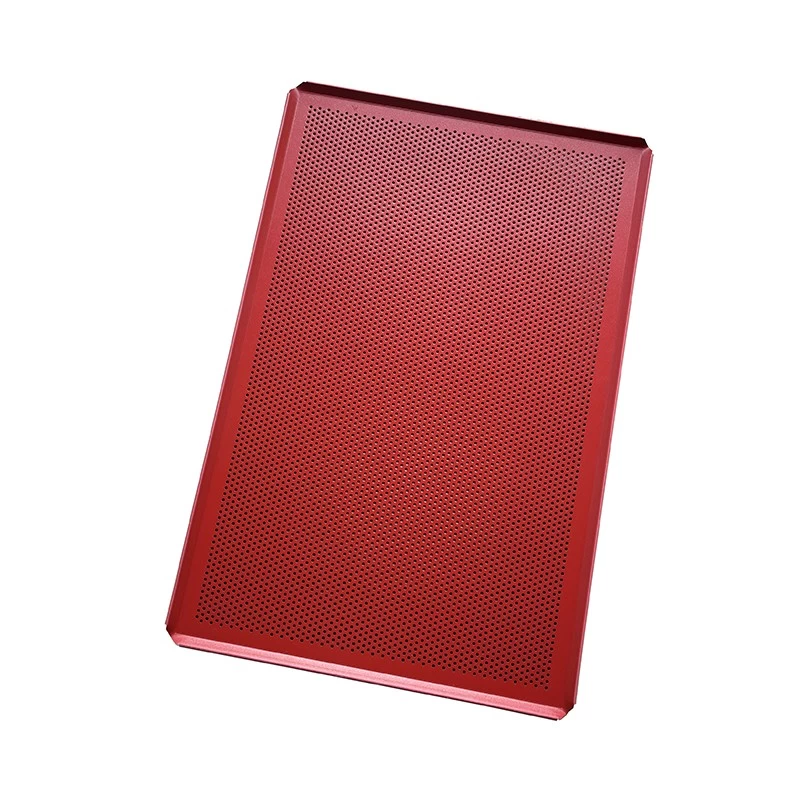

2.Perforated Design for Optimal Airflow

A perforated baguette pan is a preferred choice for professional baking. The perforations allow hot air to circulate directly around the dough, promoting:

- Crisp, well-developed crusts

- Improved moisture release during baking

- Even browning from top to bottom

For bakeries focused on traditional French baguette texture and appearance, precision-perforated holes are a critical feature that should not be overlooked.

3.Durable Non-Stick Surface Treatment

In high-output bakeries, efficiency matters. A commercial-grade baguette pan should feature a durable non-stick coating or surface treatment that can withstand repeated use.

Benefits include:

- Easy and clean release of baked baguettes

- Reduced need for excessive oil or release agents

- Faster turnaround time between baking batches

Advanced coatings such as silicone glaze or PTFE-based non-stick layers are commonly used in commercial applications, provided they are applied with strict quality control.

At Tsingbuy, our baguette pans are produced under strict quality control, using proven non-stick solutions suitable for continuous commercial baking. Each pan is carefully inspected for coating adhesion, release performance, and durability, helping professional users achieve stable results and lower operating costs. As a reliable baguette pan manufacturer in China, Tsingbuy is committed to consistent quality for commercial bakeries, restaurants, and food factory facilities.

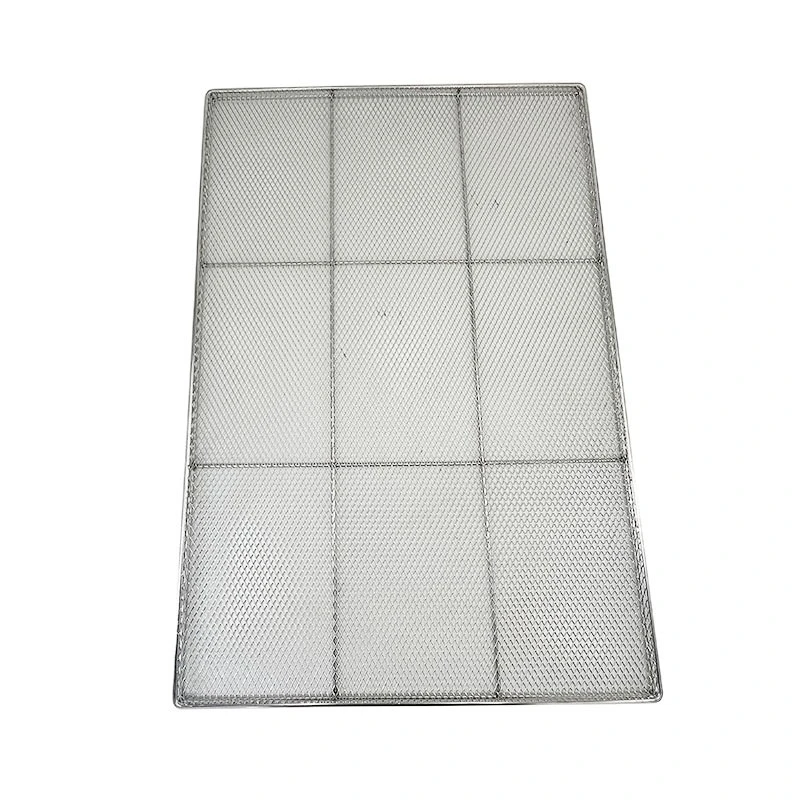

4.Reinforced Structure for Long-Term Stability

Commercial baking environments are far more demanding than home kitchens. A professional baguette pan should be designed with:

- Reinforced edges or rolled rims to prevent deformation

- Stable channel shapes that maintain form under load

- Strength to support fully proofed dough without bending

A rigid, well-engineered structure ensures consistent results over thousands of baking cycles and reduces replacement costs over time.

With years of manufacturing experience, Tsingbuy commercial baking trays factory in China specializes in French stick bread trays designed for intensive use. We are capable of producing extra-large baguette trays for industrial applications, including customized sizes for automatic machinery production lines, with dimensions reaching up to 800 × 2000 mm. Built with reinforced structures, premium materials, and precise fabrication, Tsingbuy baguette trays deliver excellent durability, dimensional stability, and long service life, even under continuous high-load production conditions.

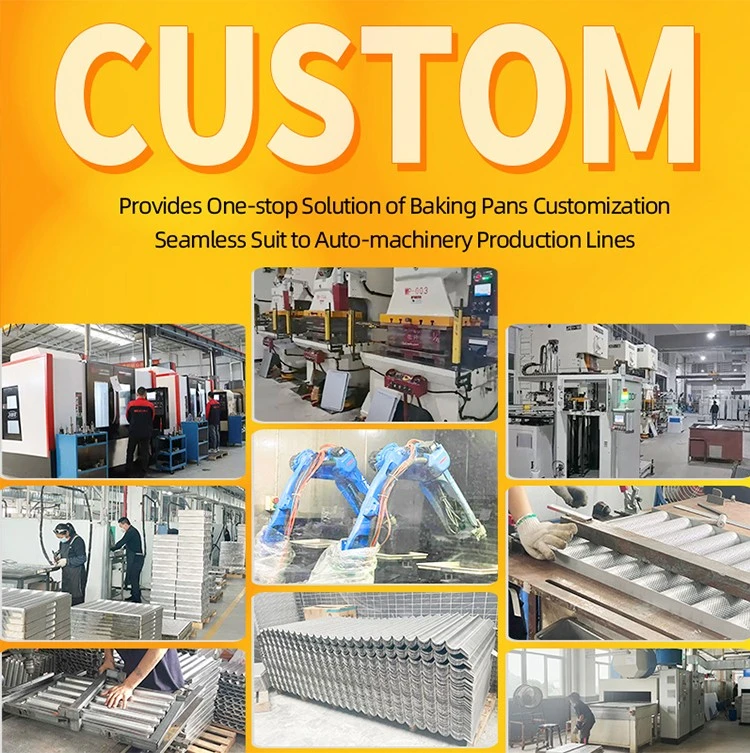

5.Customization for Commercial Ovens and Production Lines

One of the most important features of a true commercial-grade baguette pan is customization capability. Standard sizes may not always fit modern bakery ovens or automated production systems.

Look for a manufacturer that can offer:

- Custom pan length, width, and channel count

- Specific perforation patterns or hole diameters

- Compatibility with rack ovens, deck ovens, tunnel ovens, or automatic loading systems

Customized baguette pans help maximize oven capacity, improve workflow efficiency, and ensure seamless integration with your existing baking equipment.

For bakeware brands, distributors, commercial bakeries, restaurant groups, and industrial food factories, choosing the right commercial-grade baguette pan is a strategic decision that directly impacts product consistency, kitchen efficiency, equipment compatibility, and operating costs. By prioritizing material quality, perforated airflow design, reliable non-stick performance, reinforced structure, and customization capability, buyers can ensure stable, repeatable results across daily production.

As a professional French bread trays supplier in China, Tsingbuy supplies baguette pans engineered for commercial kitchens, large-scale bakeries, and automated food production facilities. We offer flexible ODM & OEM services, supporting custom sizes, channel configurations, surface treatments, and designs to match different oven types and production workflows.

Whether you are sourcing baguette pans for wholesale distribution, chain restaurants, central kitchens, or food factories, partnering with an experienced manufacturer like Tsingbuy ensures better performance, longer service life, and a stronger return on investment.

Frequently Asked Questions (FAQ) for Commercial & Industrial Buyers

1. What makes a baguette pan suitable for commercial bakeries, restaurants, and food factories?

A commercial-grade baguette pan is made from food-grade aluminum or aluminized steel, features reinforced construction to prevent warping, and is designed for frequent, high-temperature baking. For food factories, pans are often customized to fit specific ovens or automated production lines.

2. Are perforated baguette pans suitable for restaurants and commercial kitchens?

Yes. Perforated baguette pans improve airflow and moisture release, helping restaurants and commercial kitchens achieve crisp crusts and consistent color, even during continuous baking or peak service hours.

3. Can baguette pans be customized for different oven types?

Yes. Professional manufacturers can customize baguette pans to match deck ovens, rack ovens, convection ovens, tunnel ovens, and automatic loading systems, including tray size, channel quantity, perforation pattern, and edge structure.

4. What non-stick coatings are recommended for commercial use?

Silicone glaze and PTFE-based non-stick coatings are commonly used in commercial baguette pans. These coatings reduce sticking, lower oil usage, and improve efficiency when applied under strict industrial quality standards.

5. Why is OEM & ODM service important for commercial baguette pans?

OEM & ODM services allow distributors and chain bakery or food facilities to standardize specifications, apply private branding, and adapt pan designs to regional baking habits and equipment requirements.

6. How do customized baguette pans improve efficiency in food factory facilities?

Customized baguette pans optimize oven loading capacity, ensure compatibility with automated handling systems, reduce production errors, and support consistent output—critical factors for large-scale food factory operations.