Customization in Multi-Mold Baking Pans: ODM/OEM Solutions for Commercial Use

Customization in Multi-Mold Baking Pans: ODM/OEM Solutions and Custom Layouts for High-Volume Commercial Baking

Contents

- What Are Multi-Mold Baking Pans?

- Why Standard Multi-Mold Pans Are No Longer Enough

- ODM vs OEM: Understanding Customisation Options

- Key Customisation Elements in Multi-Mold Baking Pans

- Unique Layouts for Specialized Baked Goods

- Compatibility with Automatic Production Systems

- Why Choose Tsingbuy for Custom Multi-Mold Baking Pans?

- FAQ

In commercial and industrial baking, efficiency, consistency, and scalability are critical. As bakeries and food factories expand product lines and automate production, standard multi-mold pans often fail to meet specific operational requirements. This is where customization in multi-mold baking pans becomes essential.

From ODM and OEM manufacturing to tailored mold layouts for specialized baked goods, custom multi-mold pans allow commercial bakeries, central kitchens, and food factories to optimize output, reduce waste, and achieve consistent product quality across high-volume production.

1.What Are Multi-Mold Baking Pans?

Multi-mold baking pans—also known as multi-cavity pans—are trays designed with multiple identical or varied molds on a single pan. They are widely used in commercial baking for products such as:

- Cupcakes and muffins

- Hamburger buns and brioche rolls

- Mini loaves and sandwich bread portions

- Tart shells and pastry bases

- Specialty molded baked goods

In high-capacity bakeries, these pans are essential for batch uniformity and throughput, especially when integrated with ovens, depanning systems, and conveyor lines.

2.Why Standard Multi-Mold Pans Are No Longer Enough

Off-the-shelf multi-mold pans are designed for general use. However, commercial and industrial bakeries often face challenges such as:

- Non-standard product sizes or shapes

- Inefficient spacing that limits oven capacity

- Incompatibility with automatic production systems

- Insufficient structural strength for long-term industrial use

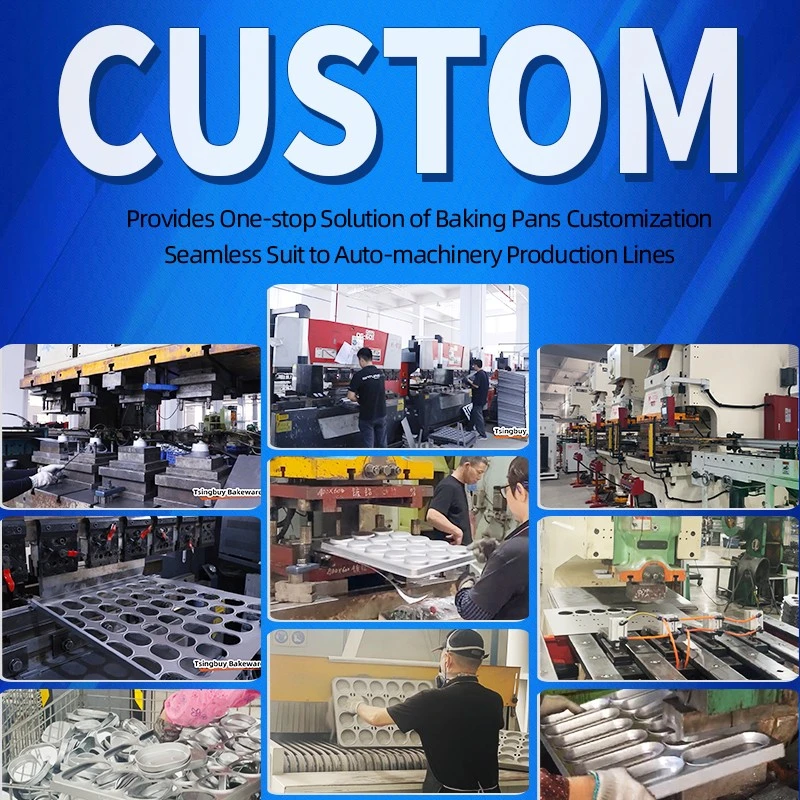

As a result, many commercial bakeries and food factories are shifting from standard products to custom-engineered multi-mold pan solutions. Tsingbuy, a professional multi-mold baking pan supplier in China since 2006, acts not only as a supplier but as a solution partner, supporting clients with application-driven design, ODM & OEM manufacturing, and reliable commercial-grade performance for industrial baking environments.

3.ODM vs OEM: Understanding Customization Options

OEM (Original Equipment Manufacturing)

OEM customisation is ideal when the client already has:

- Technical drawings or samples

- Defined mold dimensions and layouts

- Established production requirements

Tsingbuy commercial bakeware manufacturer produces the multi-mold pan strictly according to provided specifications, ensuring consistency with existing equipment and processes.

ODM (Original Design Manufacturing)

ODM services go further. In this model, Tsingbuy does the following things:

- Assists in mold layout design

- Optimizes spacing for oven and line efficiency

- Recommends materials, gauges, and coatings

- Develops prototypes for testing

For bakeries developing new products or upgrading production lines, ODM offers a collaborative, engineering-driven solution.

4.Key Customisation Elements in Multi-Mold Baking Pans

Custom multi-mold pans can be tailored in multiple dimensions to meet specific baking and production needs. Here are some basic info from Tsingbuy commercial baking pan factory in China, for your reference. Welcome to contact us at any time if you have further questions.

Mold Quantity and Layout

- Optimized cavity count for maximum oven utilization

- Custom spacing to support airflow and even heat distribution

- High-density or reduced-density layouts depending on product type

Mold Size, Depth, and Shape

- Diameter and depth matched to final product volume

- Round, square, oval, or custom-shaped molds

- Consistency across all cavities for uniform baking results

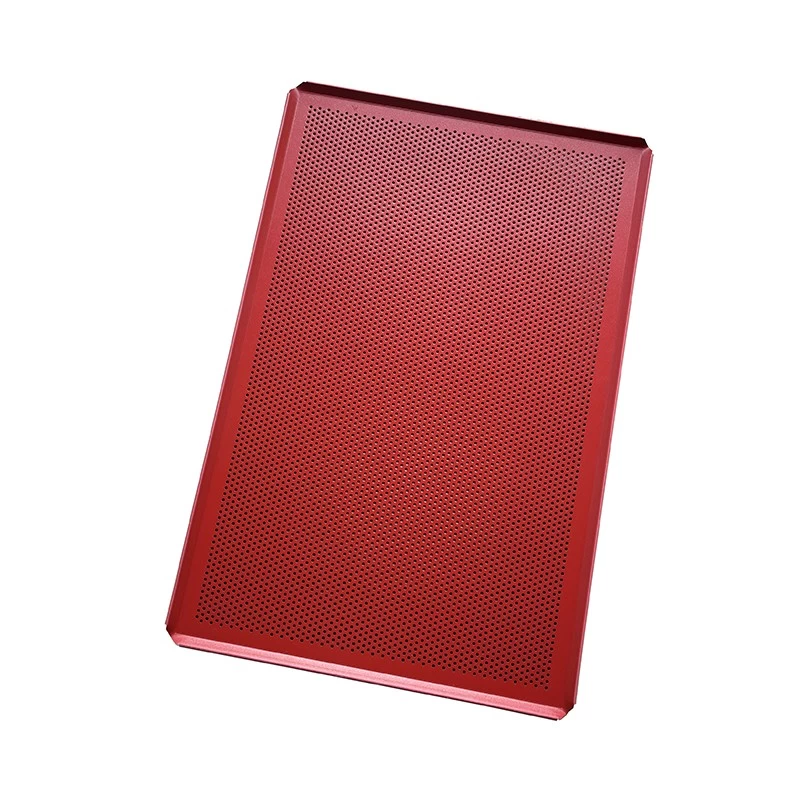

Pan Size and Industrial Formats

- Standard sizes for rack ovens and deck ovens

- Extra-large industrial pans designed for automatic production lines

- Custom dimensions to match conveyors, loaders, and depanners

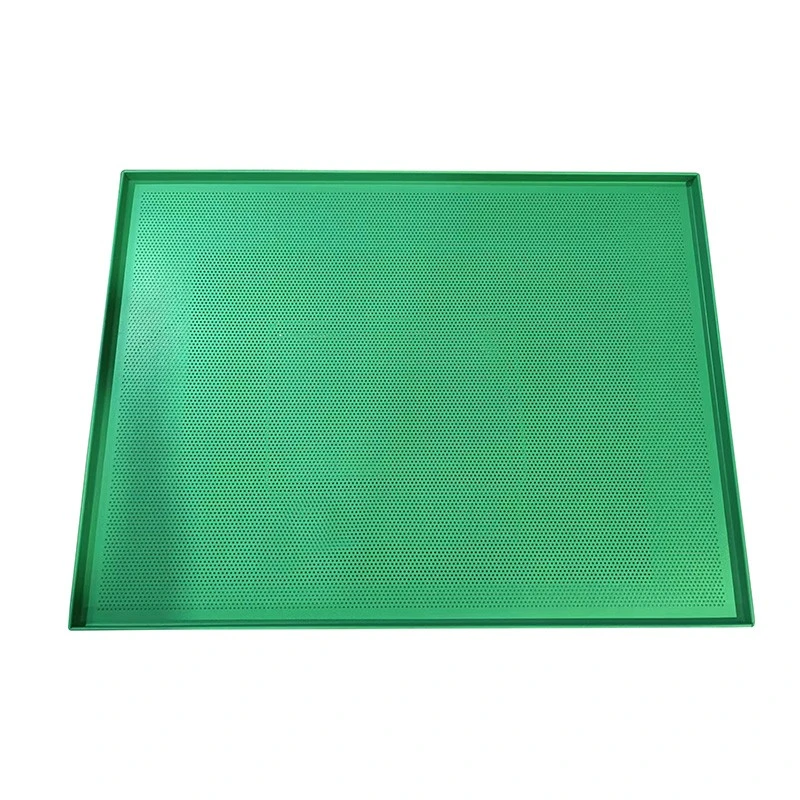

Material and Surface Treatment

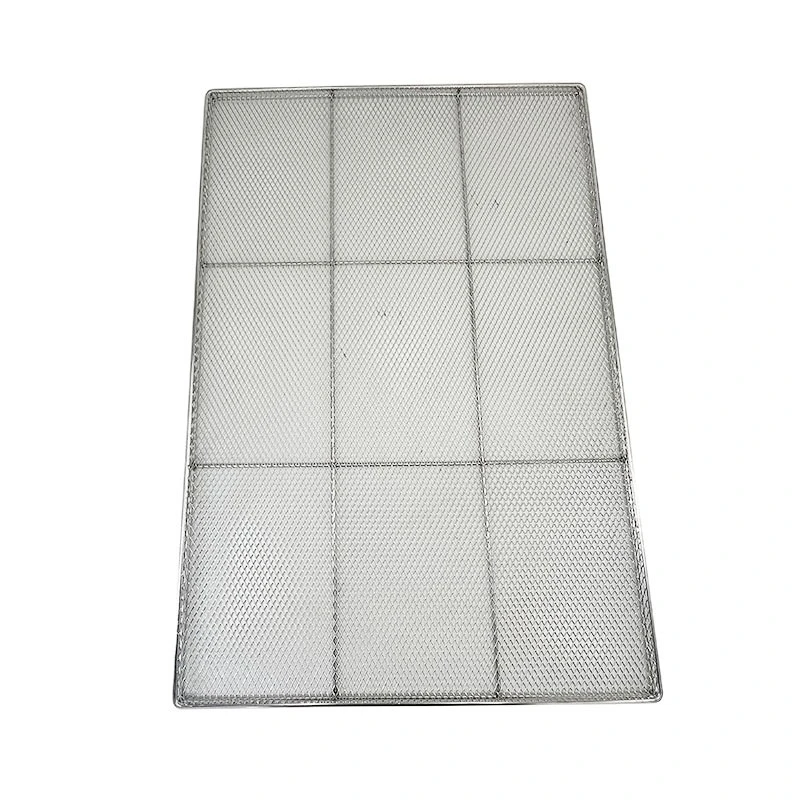

- Aluminum, aluminized steel, or stainless steel options

- Commercial-grade non-stick coatings

- Anodized aluminum for durability and easy release

Structural Reinforcement

- Reinforced edges and frames to prevent warping

- Designed for repeated high-temperature cycles

- Suitable for long-term use in industrial environments

5.Unique Layouts for Specialized Baked Goods

Specialty baked goods often require non-standard mold arrangements. Custom layouts enable:

- Irregular or asymmetrical cavity positioning

- Mixed-size molds on a single pan

- Product-specific spacing for delicate or high-sugar formulas

These layouts are especially valuable for:

- Premium bakery products

- Regional or customized bread formats

- Food factories producing private-label baked goods

6.Compatibility with Automatic Production Systems

One of the biggest advantages of custom multi-mold pans is their ability to integrate seamlessly with machinery production systems, including:

- Tunnel ovens and rotary ovens

- Automatic depanning machines

- Cooling conveyors and stacking systems

Customisation ensures:

- Accurate pan alignment

- Smooth transfer between machines

- Reduced downtime and manual handling

This level of integration is critical for food factories and large-scale commercial bakeries focused on efficiency and labor optimization.

7.Why Choose Tsingbuy for Custom Multi-Mold Baking Pans?

As a professional ODM OEM bakeware manufacturer in China with nearly 20 years of experience, Tsingbuy specializes in custom multi-mold baking pan solutions for global B2B clients.

Tsingbuy offers:

- Commercial-grade materials and coatings

- Custom mold layouts engineered for production efficiency

- Extra-large and industrial pan formats for automatic lines

- Strict quality control and durability-focused design

- Flexible ODM & OEM services for bakeries, distributors, and food factories

Whether you require precise OEM manufacturing or full ODM design support, Tsingbuy delivers reliable, scalable, and production-ready multi-mold pan solutions.

8.Frequently Asked Questions (FAQ)

(1) What is the minimum order quantity (MOQ) for custom multi-mold baking pans?

MOQ depends on the pan size, material, and level of customization. For ODM and OEM projects, MOQ is typically set to support efficient production while remaining flexible for B2B clients.

(2) Can multi-mold pans be customized to match existing bakery machines?

Yes. Custom multi-mold pans can be designed to match your existing ovens, depanners, and conveyor systems, ensuring smooth integration into current production lines.

(3) What materials are best for commercial multi-mold pans?

Aluminum and aluminized steel are commonly used for commercial baking due to their excellent heat conductivity and durability. Material selection depends on baking temperature, product type, and cleaning requirements.

(4) Do you offer non-stick coatings for custom multi-mold pans?

Yes. Tsingbuy provides multiple commercial-grade non-stick coating options, including solutions suitable for high-sugar and high-fat recipes.

(5) What is the lead time for ODM and OEM multi-mold pans?

Lead time varies based on design complexity and order volume. ODM projects may require additional time for design and prototyping, while OEM orders typically follow standard production timelines.

Customisation in multi-mold baking pans is no longer just about shape—it’s about performance, efficiency, and scalability.

With professional ODM & OEM capabilities, manufacturers like Tsingbuy help commercial bakeries and food factories turn unique product ideas into reliable, high-volume production solutions.