Reinforced Rim and Reverse-Folded Edge in Commercial Baking Sheet Pans

Contents

- 1.What are Reinforced Rims and Reverse-Folded Edge on Commercial Sheet Pans?

- 2.How Do Reinforced Rims Benefit Commercial Sheet Pans?

- 3.Why Are Reverse-Folded Edges Important for Baking Performance and Safety?

- 4.Why Do Reinforced Rims and Reverse-Folded Edges Matter in Commercial baking?

- 5.How Can You Choose the Right Sheet Pan for Your Bakery or Production Line?

- 6.What Makes Reinforced Rims and Reverse-Folded Edges a Smart Investment for Bakeries?

Commercial sheet pans are essential tools in bakery kitchens, commissaries, and large-scale food production environments. Whether used for baking bread, pastries, cookies, or roasting ingredients, they are expected to perform consistently under high temperatures, heavy loads, and continuous daily operation. In these demanding settings, the construction quality of a sheet pan directly affects workflow efficiency, product consistency, and long-term cost control.

Durability, safety, and operational efficiency are therefore critical factors when selecting commercial bakeware. A well-designed sheet pan must resist warping, withstand rapid temperature changes, and offer safe, comfortable handling for busy kitchen staff. Beyond the metal material and thickness, specific structural features play a decisive role in overall performance.

Among these features, reinforced rims and reverse-folded edges stand out as two of the most effective design enhancements for commercial sheet pans. These strengthened edges not only increase the structural integrity of the pan, but also contribute to safer handling, longer service life, and more stable baking results—making them indispensable in modern bakery operations.

1.What are Reinforced Rims and Reverse-Folded Edges on Commercial Sheet Pans?

Two of the most important edge-enhancement techniques are the reinforced rim and the reverse-folded edge.

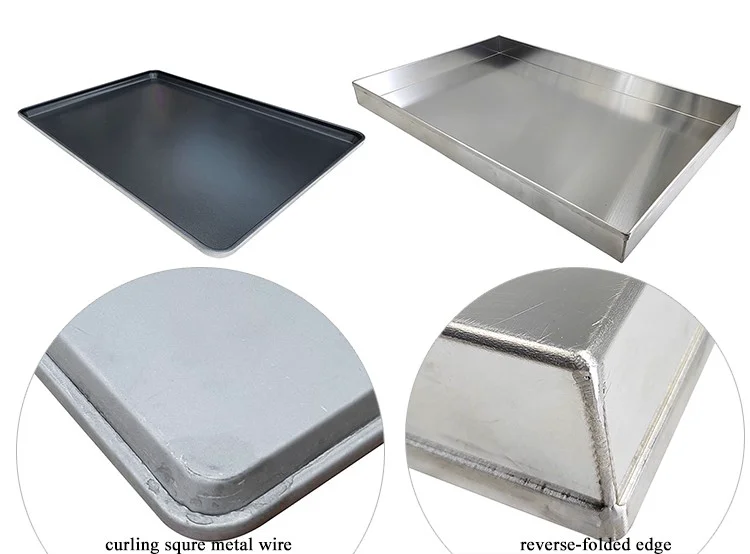

Reinforced Rim

A reinforced rim refers to the added strength along the perimeter of a sheet pan. This is typically achieved by curling a metal wire at the edge. The reinforcement creates a rigid, impact-resistant boundary that prevents the pan from bending, twisting, or warping during heavy use. In commercial environments—where pans are frequently stacked, loaded with large quantities of dough, or moved rapidly in and out of ovens—this extra strength is essential for maintaining shape and stability.

Reverse-Folded Edge

A reverse-folded edge is created when the outer rim of the pan is bent inward and folded back onto itself. This welding technique produces a smooth, rounded edge that adds structural integrity while improving safety. The folded construction eliminates sharp corners, reduces the chance of injury during handling, and enhances the rigidity of the pan. Additionally, reverse-folded edges help the pan retain its form under thermal stress, supporting even heat distribution and consistent baking results.

2.How Do Reinforced Rims Benefit Commercial Sheet Pans?

Reinforced rims are a key structural advantage in high-quality commercial sheet pans, delivering stronger performance and longer service life in demanding bakery environments. Their enhanced construction brings several important benefits:

Enhanced Durability

A reinforced rim significantly strengthens the perimeter of the pan, making it far more resistant to bending, twisting, or warping. In commercial kitchens and food factories—where pans endure high baking temperatures, heavy dough loads, and frequent handling—this added rigidity ensures the pan maintains its shape and delivers consistent baking results over time. The reinforced edge also reduces deformation caused by dropping, stacking, or daily operational stress.

Easier Handling

The curling, strengthened edge offers a firmer and more comfortable grip for bakery staff. Whether pulling pans from hot ovens, transferring loaded trays across the production line, or sliding them into racks, the reinforced curling-wire rim provides a stable hold that improves overall handling safety. This is especially valuable in fast-paced commercial environments where efficiency and safety must go hand in hand.

Better Stability

Reinforced curling-wire rims also help stabilize the pan’s structure, especially when multiple pans are stacked or stored. The reinforced perimeter supports even stacking, reduces edge denting, and prevents the pan from collapsing under weight. This feature not only protects the pans from damage but also helps maintain an organized and efficient storage system in bakeries and industrial kitchens.

3.Why Are Reverse-Folded Edges Important for Baking Performance and Safety?

Reverse-folded edges are another important design enhancement that elevate the performance, safety, and reliability of commercial sheet pans. By folding the metal rim inward and back onto itself, this construction method delivers several key advantages:

Improved Safety

Reverse-folded edges create a smooth, rounded perimeter that eliminates sharp metal edges. This greatly reduces the risk of cuts or injuries when kitchen staff are handling pans quickly during production. For commercial bakeries and food factories—where pans are used hundreds of times per day—this added safety is an important part of maintaining a professional and hazard-free working environment.

Greater Structural Strength

The folded edge reinforces the entire rim, giving the sheet pan a stronger and more rigid frame. This increased rigidity helps the pan resist warping during repeated heating and cooling cycles. It also supports better load-bearing capacity when pans are filled with dough, batter, or baked goods, ensuring that the pan stays flat and stable throughout the baking process.

More Consistent Baking Performance

A well-structured sheet pan maintains its shape even under extreme commercial conditions. The stability provided by reverse-folded edges helps promote even heat distribution across the pan’s surface. This results in more consistent browning, uniform baking, and reliable quality—essential factors for bakeries aiming for consistent output day after day.

4.Why Do Reinforced Rims and Reverse-Folded Edges Matter in Commercial Kitchens?

In commercial bakeries, food factories, and large-scale production facilities, sheet pans are essential components of an efficient and reliable workflow. Reinforced rims and reverse-folded edges play a crucial role in supporting the heavy demands of professional operations.

Built for Heavy-Duty, High-Volume Baking

Commercial environments require sheet pans that can endure continuous use, heavy dough loads, and rapid transitions between hot ovens and cooling racks. Enhanced rims and folded edges help the pans maintain their structural integrity, ensuring they perform reliably throughout long production cycles without deforming or failing.

Compatible with Automatic Machinery and Production Lines

For bakeries using conveyor systems, tunnel ovens, or automatic machinery, precision and durability are critical. Sheet pans with reinforced rims and reverse-folded edges are better suited for mechanical handling because they resist warping and maintain consistent dimensions. This ensures smoother transport on conveyors and fewer production interruptions.

Reduced Replacement Costs and Improved Long-Term Value

High-quality sheet pans may cost more upfront, but their extended lifespan results in significantly lower long-term operating costs. Reinforced rims and folded edges protect the pan from edge dents, bending, and premature wear—meaning fewer replacements and greater return on investment for commercial kitchens. For bakeries looking for specialized designs, working with Tsingbuy custom made baking pans supplier in China ensures pans are perfectly tailored to meet unique production line needs.

Enhanced Workplace Safety and Efficiency

The added strength and smoother edges help kitchen staff work more confidently and efficiently. Safer grip, faster movement, and reduced risk of injury all contribute to a more streamlined kitchen workflow.

5.How Can You Choose the Right Sheet Pan for Your Bakery or Production Line?

Selecting the right sheet pan is essential for maintaining consistent results and smooth operations in commercial baking environments. While reinforced rims and reverse-folded edges significantly enhance performance, other factors also play a key role in choosing a pan that meets your bakery’s specific needs.

Consider the Material

The metal type greatly influences heat conductivity, durability, and weight.

- Aluminum offers excellent heat distribution and is widely used in bakeries.

- Aluminized steel provides added strength and corrosion resistance, suitable for intensive industrial use.

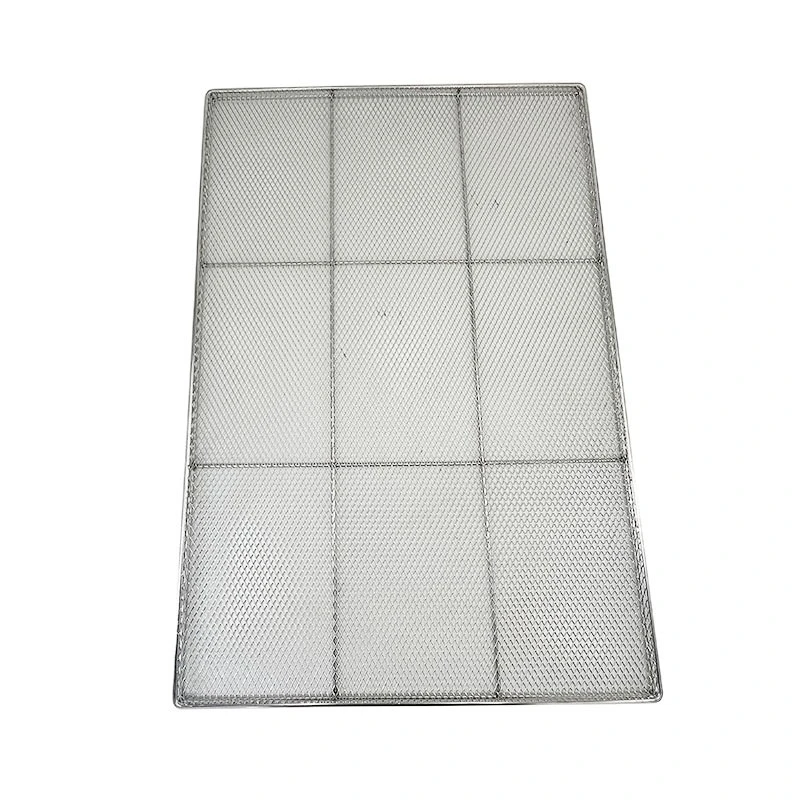

- Stainless steel is highly durable and hygienic, ideal for environments requiring strict sanitation standards.

Evaluate the Thickness

Thicker pans (such as 1.0mm, 1.2mm, or heavier gauges) provide better resistance to warping and can withstand the demands of commercial ovens and daily handling. A professional-grade thickness is essential for long-term stability.

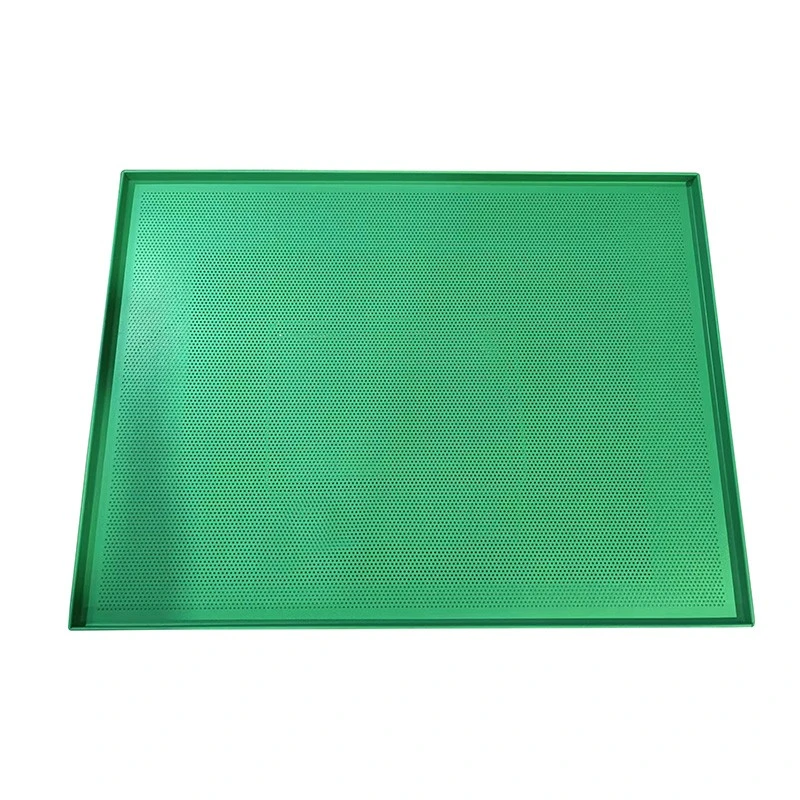

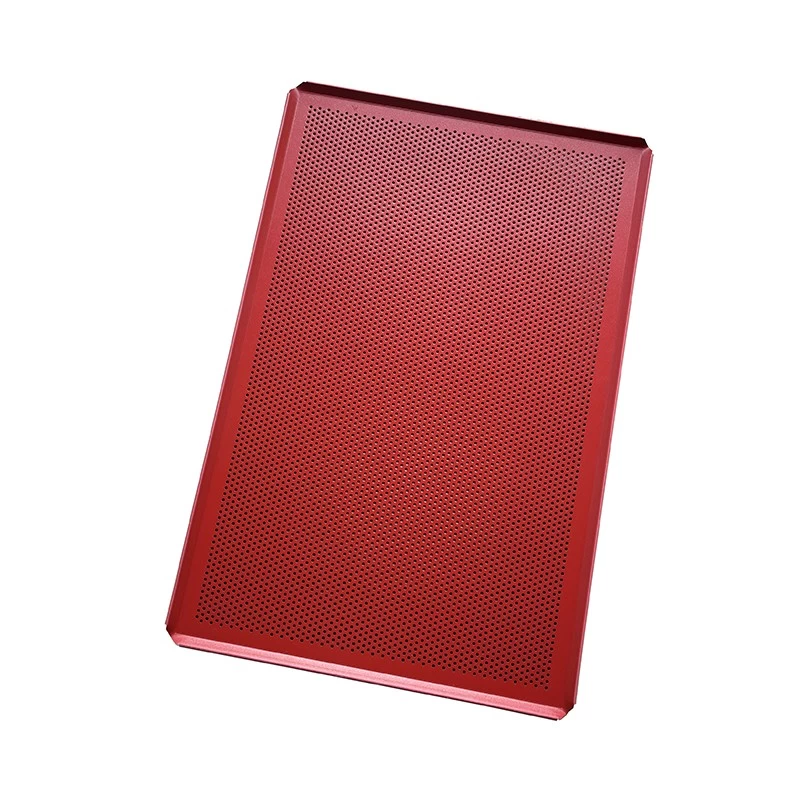

Non-Stick and Perforation Options

Depending on the application, you may require:

- Non-stick coating for easy release and fast cleaning.

- Perforated pans for improved airflow and crispier baking results.

Selecting these features based on your baking requirements will directly impact your finished products.

Choose the Right Sizes and Formats

Commercial sheet pans come in full-size, half-size, and various depths to support different production needs. Matching the size to your oven type, rack spacing, and production line ensures smoother operation.

Customization for Specialized Production Lines

For bakeries using automatic machinery or unique production systems, custom sheet pans may be essential. As a professional bakeware manufacturer, Tsingbuy commercial sheet pans manufacturer in China provides customization services including:

- Custom sizes

- Material and thickness options

- Reinforced structures

- Special surface treatments

- Design matching for automatic production lines

Tailored pans ensure perfect compatibility with your equipment and help maximize output efficiency.

6.What Makes Reinforced Rims and Reverse-Folded Edges a Smart Investment for Bakeries?

For bakeries, food factories, and industrial production lines, Reinforced rims and reverse-folded edges help ensure consistent baking results, smoother handling, longer pan lifespan, and more efficient day-to-day operations.

As production demands grow, investing in high-quality sheet pans with these strengthened edges becomes a practical and cost-effective decision. By choosing pans engineered for heavy-duty use—and selecting the right material, thickness, and customization options—bakeries can significantly improve both workflow efficiency and product quality.

For professional and specialized needs, Tsingbuy industrial baking tray factory in China provides a full range of commercial-grade sheet pans with reinforced rims, reverse-folded edges, and complete ODM & OEM customization services. Our solutions are designed to support automatic machinery production systems and help bakeries achieve higher levels of performance, consistency, and reliability.