Custom Multi-Mold Baking Pans for Automatic Bakery Lines: Boosting Efficiency, Consistency, and Output

Contents

- 1. Introduction: The Shift Toward Automation in Modern Bakeries

- 2. What Are Custom Multi-Mold Baking Pans?

- 3. Why Automatic Bakery Lines Require Custom Trays

- 4. Key Benefits of Custom Multi-Mold Pans

- 5. Customization Options from a Professional Manufacturer

- 6. Case Example

- 7. Maintenance and Lifespan Tips

- 8. Conclusion: Enhancing Productivity with Custom Industrial Bakeware

1. Introduction: The Shift Toward Automation in Modern Bakeries

In today’s baking industry, automation has become more than a trend—it’s a defining transformation. Modern commercial bakeries and large-scale food factories are increasingly adopting automatic production systems to achieve higher output, stable quality, and consistent product performance. From dough mixing and shaping to proofing and baking, each stage is now integrated into a seamless, continuous process that minimizes manual handling and maximizes efficiency.

Within these automated bakery lines, the demand for custom multi-mold baking pans has grown rapidly. Standard trays often fail to match the exact specifications of conveyor systems, loaders, and tunnel ovens, leading to misalignment or uneven baking. Custom-fit pans, designed to match precise machinery dimensions and production layouts, ensure every mold aligns perfectly with the automated workflow—resulting in smooth operation and uniform baked goods in every batch.

As a professional industrial bakeware manufacturer in China, Tsingbuy understands the technical requirements of automation. With nearly 20 years of experience, we provide ODM & OEM solutions for custom multi-mold baking pans engineered to fit various machinery production systems. Whether for hamburger buns, muffins, donuts, or hot dog rolls, each tray is built to commercial-grade standards, delivering durability, precision, and compatibility for automated baking lines worldwide.

2. What Are Custom Multi-Mold Baking Pans?

A multi-mold baking pan is a specially designed tray featuring multiple identical molds fixed within one durable frame. It enables bakeries and food factories to bake dozens of uniform products in a single batch—greatly improving efficiency, consistency, and output. These pans are widely used for products such as hamburger buns, muffins, cupcakes, madeleines, donuts, hot dog buns, and croissants, making them indispensable in large-scale commercial baking.

Unlike standard single-mold or household pans, custom multi-mold pans are engineered to meet the precise requirements of industrial bakery machinery. Every detail—from the pan’s outer dimensions to the arrangement and size of each mold—is designed according to the layout of the production line. This ensures the pans fit perfectly into conveyors, tunnel ovens, rotary rack ovens, and other automatic baking systems without adjustment.

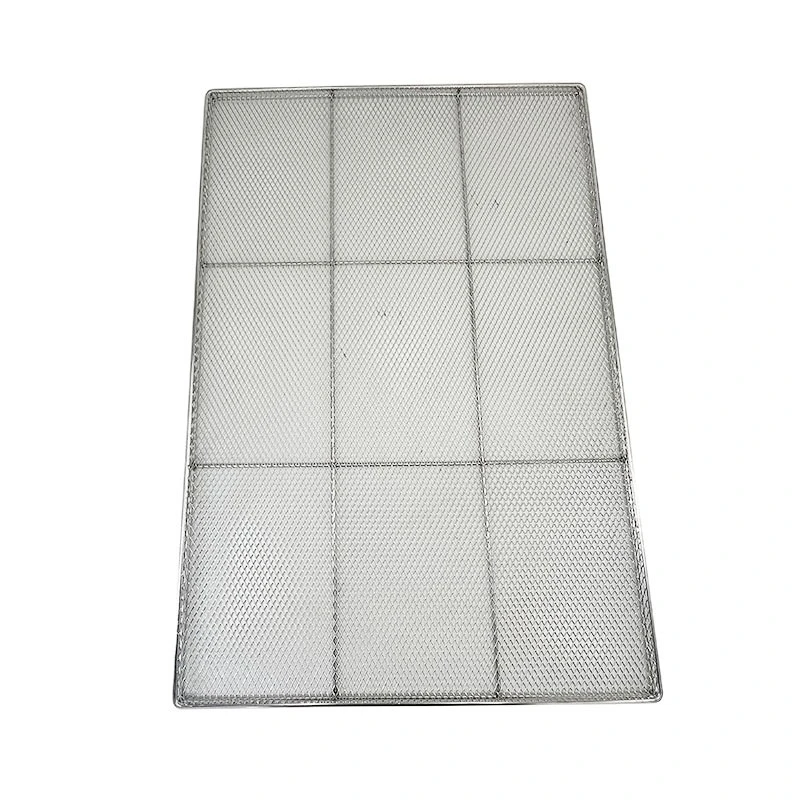

The materials used are typically aluminized steel, stainless steel, carbon steel, or aluminum, each chosen for its strength, heat conductivity, and long service life. To enhance release and protect the surface, Tsingbuy offers various surface treatments, such as Teflon non-stick coating, silicone glaze, or anodized aluminum finishes. Reinforced strap frames or wire supports can also be added to ensure rigidity and prevent deformation under continuous high-temperature baking cycles.

In short, custom multi-mold baking pans are the foundation of efficient, automated baking. They combine intelligent design, precision manufacturing, and durable materials to help commercial bakeries achieve consistent results on every batch.

3. Why Automatic Bakery Lines Require Custom Trays

In an automatic bakery production system, every component must operate in perfect synchronization—from dough feeders and molding machines to proofers, ovens, and cooling conveyors. This high level of precision leaves no room for mismatched equipment. That’s why custom multi-mold baking pans are essential—they ensure seamless integration with machinery and maintain consistent performance throughout the production cycle.

Standard pans often vary slightly in size or frame design, which can cause misalignment when used on automatic loaders or conveyors. Even minor dimensional differences may lead to uneven baking, mechanical jams, or inefficient loading and unloading. Custom trays, on the other hand, are engineered to match the exact specifications of the bakery’s equipment—whether that’s the tray width of a tunnel oven, the pan spacing of a rotary rack, or the feeding position of an automatic depositor.

Beyond compatibility, custom multi-mold pans also contribute to product quality. When the pan layout aligns perfectly with the machinery, each mold receives uniform heat and airflow, resulting in evenly baked products with consistent color and texture. Automated bakeries require bakeware that can withstand continuous, heavy-duty use. Custom-designed pans built with commercial-grade materials and reinforced structures offer long-term durability and dimensional stability, minimizing deformation and replacement costs over time.

In essence, custom trays are not just accessories—they are integral components of the automatic bakery line, ensuring efficiency, consistency, and operational reliability at every stage.

4. Key Benefits of Custom Multi-Mold Pans

Custom multi-mold baking pans bring significant advantages to commercial bakeries and food factories that rely on automatic production systems. By combining precision engineering with tailored design, these pans help maximize productivity, ensure consistent product quality, and extend the service life of bakery equipment.

1. Consistent Product Shape and Size

Each mold within a custom tray is designed to produce uniform products, ensuring that every bun, muffin, or donut maintains the same size, weight, and appearance. This consistency is vital for brands that depend on standardized product presentation and accurate portion control.

2. Optimized Production Efficiency

When pans are perfectly aligned with the machinery’s dimensions, loading, baking, and unloading processes become seamless. This reduces downtime, prevents tray jams, and allows continuous operation at high speed—critical for large-scale production lines.

3. Improved Baking Performance

Custom multi-mold trays are engineered for even heat transfer and proper airflow. Whether used in a tunnel oven, rotary rack oven, or convection system, the optimized mold arrangement ensures uniform browning, stable texture, and ideal crust formation across all products.

4. Reduced Labor and Handling

Automation minimizes manual intervention, and custom-fit trays enhance that efficiency. Operators can move trays directly from one stage to another—mixing, proofing, baking, cooling—without the need for repositioning or adjustment, which improves hygiene and saves time.

5. Enhanced Durability and Service Life

Manufactured from commercial-grade aluminized steel, stainless steel, or aluminum, these pans withstand high heat and continuous operation. Reinforced frames and optional non-stick coatings further increase longevity, making them a cost-effective investment for industrial bakeries.

6. Perfect Compatibility with Automatic Systems

From the layout of the molds to the outer pan size, every detail is customized to integrate with automatic depositors, conveyors, and loaders. This precision fit ensures smooth performance throughout the entire machinery production system.

5. Customization Options from a Professional Manufacturer

Every commercial bakery has unique production requirements, and a one-size-fits-all baking tray rarely meets the demands of an automated bakery line. That’s why custom multi-mold pans are critical—and why partnering with a professional manufacturer like Tsingbuy can make all the difference.

- Tailored Layouts and Dimensions

Custom trays can be designed with precise mold arrangements, rows, and columns to fit your specific machinery dimensions. Whether it’s a 600×400 mm tray for muffins, an 800×2000 mm hamburger bun pan, or a uniquely shaped tray for croissants, each design ensures perfect alignment with conveyors, loaders, and ovens.

- Diverse Mold Shapes and Sizes

From round cupcakes to oval hot dog buns or rectangular sandwich loaves, Tsingbuy can craft multi-mold pans in virtually any shape and size. This flexibility allows bakeries to produce a wide variety of baked goods without compromising efficiency.

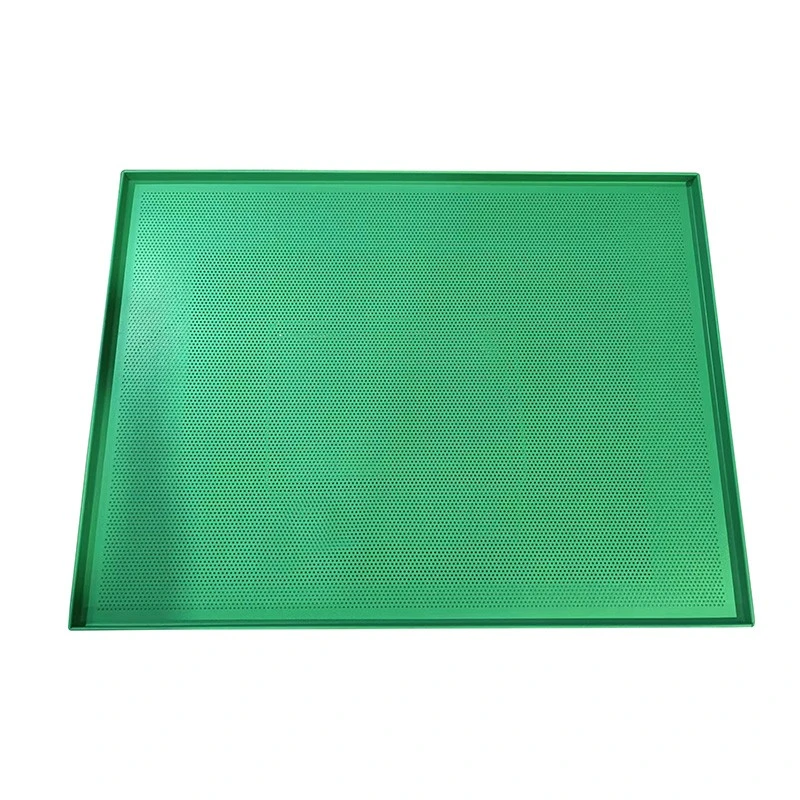

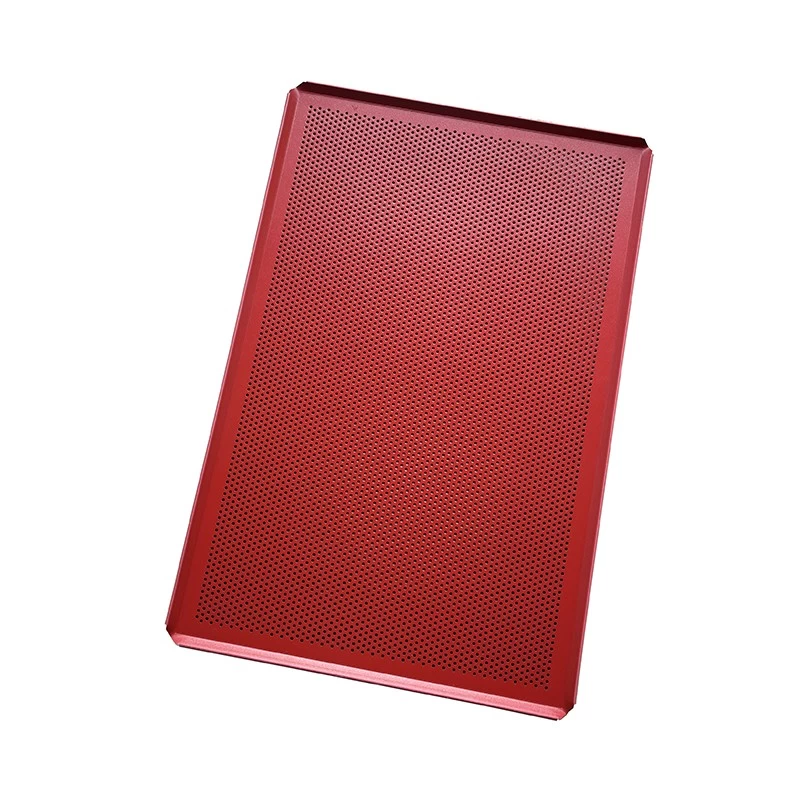

- Surface Treatments and Materials

Depending on baking requirements, trays can be made from aluminized steel, stainless steel, carbon steel, or aluminum, and finished with coatings such as Teflon, silicone glaze, or anodized surfaces. These treatments improve non-stick performance, durability, and heat distribution, extending the tray’s service life.

- Reinforced Structures for Heavy-Duty Use

For high-speed automatic lines, trays can be equipped with strap frames or reinforced edges to prevent warping, bending, or damage under continuous baking conditions.

- ODM & OEM Services

Tsingbuy multi-mold baking pans supplier in China specializes in ODM & OEM solutions, offering light customization or fully tailored designs based on your production line specifications. Our team works closely with clients to translate operational needs into high-performance baking trays compatible with machinery production systems.

- Integration with Automation

Each tray is engineered to seamlessly fit into automatic loaders, depositors, proofers, and ovens. This integration ensures smooth operation, consistent product quality, and maximum throughput for your bakery.

By leveraging these customization options, bakeries can optimize production efficiency, reduce downtime, and deliver consistent, high-quality baked goods—while relying on Tsingbuy’s nearly 20 years of expertise in industrial bakeware manufacturing.

6. Case Examples: Custom Multi-Mold Trays in Action

To illustrate the impact of custom multi-mold baking pans, here are several examples of how bakeries and food factories have optimized their production lines with Tsingbuy’s solutions:

- 800×800 mm Round Muffin Pan

A commercial bakery producing muffins for retail chains required high-capacity, uniform trays. Tsingbuy designed an 800×800 mm round muffin pan with precise mold spacing and durable construction, ensuring consistent browning and perfect muffin shape in every batch.

- 800×2000 mm Baguette Pan with 21 Slots

For an industrial bakery producing large-volume baguettes, Tsingbuy delivered a custom 800×2000 mm tray with 21 perfectly aligned slots. The tray fits seamlessly into automated rack ovens, improving baking consistency and maximizing production output.

- 80-Mold Mini Round Cupcake Pan

A specialty bakery required high-output trays for mini cupcakes. Tsingbuy provided an 80-mold mini round cupcake tray, engineered for uniform baking, easy handling, and smooth integration with the bakery’s automatic depositor and oven system.

- 70-Mold Square Muffin Baking Pan

To meet demand for large batches of square muffins, Tsingbuy created a 70-mold square muffin pan with optimized spacing and reinforced frame, enabling even baking and high-speed production without warping.

- 735×503 mm Hamburger Pan with 24 Molds

A food factory producing hamburger buns needed a tray that combined durability with high-temperature performance. Tsingbuy designed a 735×503 mm hamburger pan with 24 molds, featuring powder Teflon coating for non-stick performance and a square tube wire rim for extra strength and long-lasting stability.

In addition to these examples, Tsingbuy also offers a wide range of multi-mold baking pans for donuts, croissants, madeleines, and other specialty baked goods, providing flexible solutions for automated bakery production needs.

7. Maintenance and Lifespan Tips

Even the best custom multi-mold baking pans perform optimally only when properly maintained. Following simple care practices can extend their lifespan and ensure consistent results in high-volume production:

Proper Cleaning: Clean trays after each baking cycle using mild detergents and non-abrasive tools to preserve coatings and prevent corrosion. Avoid metal utensils that can scratch non-stick surfaces.

Gentle Handling: When loading and unloading trays from conveyors, ovens, or racks, handle them carefully to avoid bending or warping. Reinforced trays are more durable, but care still matters.

Temperature Management: Avoid sudden temperature changes that can stress materials and coatings. Preheating ovens gradually and cooling trays gradually after baking helps maintain structural integrity.

Regular Inspection: Check trays for signs of wear, coating damage, or warping. Timely replacement of worn trays maintains consistent product quality and prevents equipment issues.

By following these practices, bakeries can maximize the service life of their custom trays while ensuring uniform baking performance throughout continuous production cycles.

8. Conclusion: Enhancing Productivity with Custom Industrial Bakeware

In today’s automated bakery landscape, custom multi-mold baking pans are more than just tools—they are integral components of efficient, high-output production lines. Properly designed trays ensure consistent product quality, seamless integration with machinery, and long-lasting durability, helping bakeries achieve operational excellence.

Tsingbuy, since 2006, with nearly 20 years of experience as a professional commercial baking tray factory in China, provides ODM & OEM solutions for custom multi-mold trays, delivering products that fit perfectly into automatic bakery lines worldwide. Whether producing hamburger buns, muffins, donuts, or specialty pastries, our commercial-grade trays provide the precision, efficiency, and reliability modern bakeries need to succeed.

Whether your bakery is upgrading its production system or launching a new line, partnering with Tsingbuy ensures that your bakeware is customized, durable, and fully compatible with your automated equipment—helping you achieve maximum productivity and consistent excellence.