Custom Case: Trolley Shelf & Trays & LED lights

At the end of 2019, we designed and manufactured trolley shelf with trays and LED lights for plant seedling cultivation company. After sample confirmation in 2019, we get batch production and finish the shipment at the end of 2020. Here we would like to share the custom procedures with you.

Step One: received customer’s requirements

|

Original Demands |

|

|

Product |

Trolley shelf with flat trays |

|

Size |

1300x600x1900mm, 13 layers |

|

Material |

Stainless Steel |

|

Function |

Unknown |

|

Special feature |

Need 2 rails to insert LED plates under each flat trays |

|

Quantity |

100sets |

Step Two: confirm with customer for more detals (Ⅰ)

|

Details confirmed |

|

|

Function |

Provide space layer frame and light source for some photocultured seeds, make plants germinate and cultivate seedlings.

|

|

Layer distance |

The distance between each layer |

|

LED lights |

13 LED plate lights for each trolley shelf; Relationship between installation mode and rails; Required specifications for LED lights (still under discussion); |

Step Three: confirm with customer for more details (Ⅱ)

|

Details confirmed |

|

|

Bearing |

Load bearing requirements for each layer and the whole trolley shelf; |

|

Flat tray |

The tray material, thickness and workmanship |

|

application |

Know more about the trolley shelf application details from cutomer, helping us to design the product with better user experience. |

|

LED lights |

Required specification for LED are still under discussion |

|

Thermal conductivity |

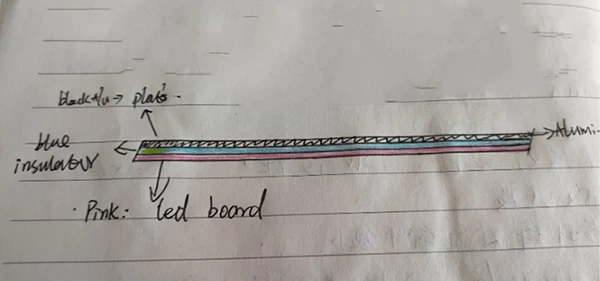

Thermal conductivity is a problem as it will affects plants growing. We choose to apply polystyrene insulator board,10mm thickness, 80℃ heat-resistance, which is light and good in heat resistance, what is more, it saves cost for customer.

|

Step Four: confirm with customer for more details (Ⅲ)

|

1 |

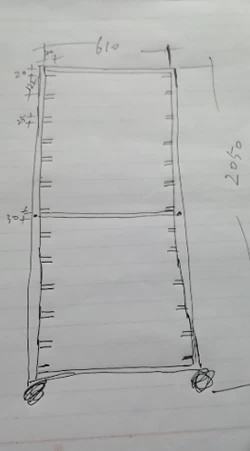

Hand-drawing for each layer structure |

|

|

2 |

Hand-drawing for trolley shelf |

|

|

3 |

LED lines stucture |

|

|

4 |

Each layer |

3 items in each layer |

|

5 |

Trolley and trays |

The biggest height for the whole trolley shelf is 2050mm; The distance between each layer is 12-13cm; Thus, the trolley can only be made into 12 layer, rather than 13 layers. The tray thickness is 1.5mm aluminium and the load bearing capacity is 15-20kg for wach layer. |

|

6 |

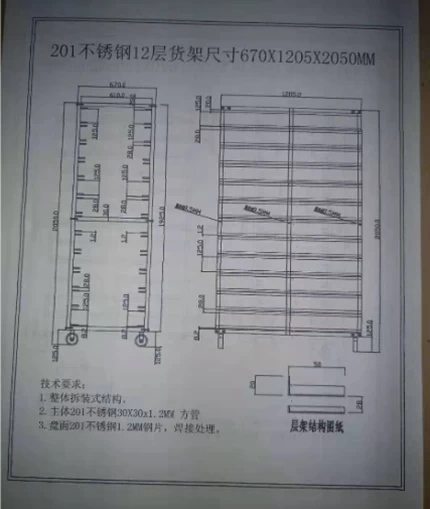

Professional chart |

|

|

7 |

sample |

Waiting fr LED lights from factory, to assemble one sample set and send it to customer for confirmation. |

|

8 |

Our advantage |

The trolley shelf is big in size. We quoted the detachable trolley shelf which saves the 100sets volumn from 147CBM to 40CBM. The volumn is reduced 73% and saves the shipping cost of a high ontainer and small container. We also provide wood pallets packing to ensure no damage from shipping. The trolley material is solid 1.2mm thick 201 stainless steel (while generally speacking the trolley shelf is 0.8/1.0mm in the market). There is no problem for bearing capacity of 240KG and 12pcs flat trays in big size, and 12pcs LED light plates. |

|

Quotation |

Since the only requirement for tray is rust-resistance, and there is no food grade requirements, we suggested customer and finally agreed to change the trays in previous quotation to 3 smaller size trays(400x600mm), made in aluminized steel, welded in corners and with reversed edges. This change helped saving the tray cost and also improve the bearing capacity up to 30KGS per layer. (each tray for 10KG).

|

|

Trial assembling |

Need to wait for cooperated LED light supplier to improve the LED light solution, to solve power line safety question.

|

|

Sample confirmation |

Improved power lines solution, as following

|