How to Choose Cookie Baking Sheet?

Selecting the right cookie baking sheet is key to achieving perfect baking results, whether you're baking at home or for a commercial operation. Tsingbuy commercial baking sheet factory in China organizes and writes this comprehensive guide which will explore the crucial factors to consider, from choosing between aluminum, stainless steel, and nonstick finishes to understanding the practical differences between rimmed and rimless styles. We'll also delve into how gauge thickness affects heat distribution, the unique benefits of perforated sheets, and how the factors impact the final bake. To top it off, we'll provide tips for maintaining your baking sheets for long-term use and introduce custom options tailored for professional bakers. Let’s uncover everything you need to know to select the ideal baking sheet and enhance your baking results!

Main Contents

- Material Matters: Aluminum, Stainless Steel, or Aluminized Steel ?

- Gauge and Thickness: Why It Matters for Even Baking

- Rimmed vs. Rimless: Choosing the Right Style for Your Needs

- Nonstick Coating or Uncoated? A Guide for Home and Commercial Bakers

- Why Size and Shape Are Important

- Perforated Baking Sheets: Are They Worth It?

- Maintenance Tips for Longevity

- Custom Baking Sheets for Professional Bakers

Material Matters: Aluminum, Stainless Steel, or Aluminized Steel ?

Aluminum is a standout material in the baking world, celebrated for its exceptional heat conduction and versatility. Here’s why it remains a top choice for various baking needs:

Superior Heat Conduction: Aluminum excels at conducting heat efficiently. It absorbs and distributes heat evenly across its surface, ensuring your baked goods cook uniformly without the risk of hot spots that can cause uneven or burnt areas.

Fast Heating: Aluminum’s rapid heating capabilities allow your oven to reach the desired temperature quickly. This feature is invaluable for bakers who require precise temperature control or are short on time.

Consistent Baking Results: Thanks to its even heat distribution, aluminum bakeware promotes consistent results in cookies, cakes, bread, and more. Expect evenly browned surfaces and uniform textures every time.

Lightweight and User-Friendly: Compared to heavier materials like cast iron or ceramic, aluminum is lightweight and easy to handle. This makes it convenient for transferring pans in and out of the oven.

Cost-Effective: Aluminum bakeware offers high performance at an affordable price, making it a practical choice for both novice and experienced bakers.

Non-Reactive Properties: Aluminum doesn’t react with acidic ingredients like tomatoes or citrus, ensuring your baked goods retain their intended flavors and appearance without discoloration.

Easy to Maintain: Aluminum bakeware is simple to clean and care for. Whether it’s coated with nonstick material or used with a light layer of oil, it resists sticking and typically requires only gentle handwashing to stay in great condition.

With its combination of performance, affordability, and ease of use, aluminum bakeware remains a trusted favorite in both home and professional kitchens.

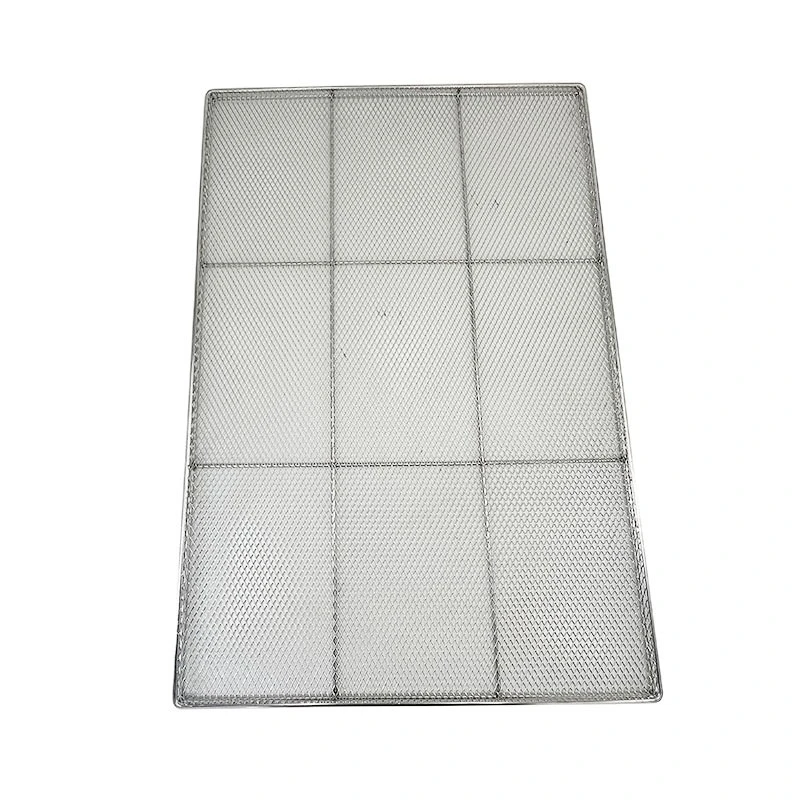

Stainless steel is a durable, versatile, and widely favored material in the kitchen, thanks to its resistance to rust, staining, and high heat. Below are its key characteristics and benefits:

Exceptional Durability: Stainless steel is highly resistant to cracks, chips, and dents, making it ideal for heavy-duty kitchen use. Its long lifespan ensures it’s a cost-effective choice.

Rust and Corrosion Resistance: Containing chromium, stainless steel forms a protective layer when exposed to oxygen, making it resistant to rust and corrosion even when exposed to moisture, acids, or salt.

Stain Resistance: Stainless steel maintains its polished appearance and resists discoloration or odors, even after contact with stain-prone ingredients like tomatoes or sauces.

High Heat Tolerance: Suitable for high-temperature cooking methods such as searing, browning, and deglazing, stainless steel can also move seamlessly from stovetop to oven without warping.

Non-Reactive Surface: Its non-reactive nature ensures it doesn’t interact with acidic or alkaline foods, preserving the taste and color of dishes.

Easy Maintenance: Stainless steel is simple to clean, dishwasher-safe, and resistant to odors, making upkeep hassle-free.

Timeless Aesthetic: Its sleek, modern design complements various kitchen styles, making it a favorite for home and professional kitchens alike.

Versatile Use: From sautéing and boiling to frying and simmering, stainless steel adapts to diverse cooking techniques.

With its unparalleled durability, practicality, and style, stainless steel remains a go-to material for cookware and utensils in any kitchen.

Aluminized steel, or alusteel, combines the best properties of aluminum and steel, offering excellent heat conductivity, durability, and versatility.

Efficient Heat Conductivity: Alusteel evenly distributes heat across its surface, ensuring consistent baking or cooking results—critical for achieving uniform textures in baked goods.

Exceptional Durability: Inheriting the strength of steel, alusteel is highly resistant to dents, cracks, and scratches, making it a long-lasting choice for kitchenware and demanding applications.

Corrosion Resistance: Its aluminum-silicon alloy coating protects against rust and corrosion, even in moisture-rich environments, ensuring reliability in both kitchen and industrial settings.

Non-Reactive Surface: Like stainless steel, alusteel is non-reactive with acidic or alkaline ingredients, preserving the taste and safety of food during preparation.

Cost-Effectiveness: Alusteel provides many benefits of pure aluminum or stainless steel at a more accessible price, making it a practical choice for budget-conscious buyers.

Resistance to Warping: Its structural stability minimizes the risk of warping under high temperatures, making it ideal for baking or other high-heat applications.

Easy Maintenance: With a smooth surface or nonstick coating, alusteel is easy to clean and resists food residue, simplifying post-use cleanup.

Versatile Applications: Suitable for a wide range of bakeware, including cake pans, bread pans, and cookie sheets, alusteel is also valued in industrial uses requiring heat resistance and durability.

Aluminized steel’s blend of performance, affordability, and versatility makes it a standout material for both professional and home kitchens.

Gauge and Thickness: Why It Matters for Even Baking

The gauge and thickness of baking materials like aluminum, stainless steel, and aluminized steel play a crucial role in determining how heat is conducted and distributed, directly influencing baking results. Understanding these factors can help bakers select the ideal bakeware for their needs.

For aluminum bakeware, a lower gauge number (indicating thicker material) typically enhances heat distribution. Thicker aluminum sheets heat more evenly, minimizing hot spots that can lead to uneven baking. This is particularly important for delicate items like cookies or pastries, where consistency in texture and browning is essential. Conversely, thinner aluminum sheets, while lighter and quicker to heat, are more prone to warping and may result in unevenly baked goods, especially at higher oven temperatures. The most suitable thickness of aluminum metal is 0.8-1.2mm.

Stainless steel, known for its durability, is a poor heat conductor compared to aluminum. Therefore, the thickness of stainless steel bakeware becomes even more significant. A thicker gauge improves heat retention and reduces temperature fluctuations, ensuring baked goods cook more uniformly. Thinner stainless steel pans can cause uneven heat distribution, leading to overcooked edges and undercooked centers. For best results, many stainless steel pans incorporate aluminum or copper cores to enhance conductivity while maintaining their structural integrity. The thickness of stainless steel should be at least 18-hauge(0.48mm).

Aluminized steel combines the conductivity of aluminum with the strength of steel, making its gauge and thickness essential for performance. Thicker aluminized steel pans excel at distributing heat evenly, allowing for consistent baking results and reducing the likelihood of hotspots. Their rigidity also makes them less prone to warping, even at high temperatures. Thinner aluminized steel, while more affordable and lightweight, may not offer the same evenness in heat distribution and could result in unevenly baked products, especially for large batches or heavy doughs. The preferred thickness of aluminized steel is 0.5-0.8mm.

The gauge and thickness of bakeware significantly affect how evenly heat is distributed and retained. Thicker bakeware materials, regardless of type, tend to yield more consistent results by minimizing temperature fluctuations and hotspots. However, they may take longer to preheat and require slightly more energy. On the other hand, thinner bakeware heats up quickly but can lead to inconsistent baking and potential warping under high temperatures. Choosing the appropriate thickness based on the material and baking needs is essential for achieving optimal results in both home and commercial kitchens.

Rimmed vs. Rimless: Choosing the Right Style for Your Needs

When choosing a baking sheet, the style—rimmed or rimless—can significantly impact its functionality and the results of your baking endeavors. Each style offers distinct advantages that cater to different needs, so understanding these differences can help you make the best choice for your kitchen.

Rimmed baking sheets, also known as baking trays, feature raised edges around the perimeter of the pan. These edges provide several key benefits, making them versatile and practical for a variety of baking tasks. The raised rim allows for easy handling, reducing the risk of spills during transport to and from the oven. This makes them ideal for tasks like baking large batches of cookies, roasting vegetables, or baking sheet cakes where spills could be messy. The raised edge also helps retain liquids, such as those released from meats during roasting, preventing them from running off the pan. Additionally, the rim can serve as a handle for easier maneuvering, especially when the pan is hot, making rimmed sheets a more functional choice for bakers looking to handle more substantial bakes.

Rimless baking sheets, on the other hand, are designed without any edges, offering a flat surface for baking. These sheets are particularly advantageous for tasks that require quick and easy access, such as sliding cookies or other baked goods onto a cooling rack after baking. The absence of a rim makes it easier to transfer baked goods directly from the pan to a cooling surface, reducing the risk of breakage and ensuring a cleaner release from the pan. Rimless sheets are also perfect for delicate bakes like thin cookies or pastries, where maintaining the integrity of the product is essential. They are lightweight and can easily be stacked for storage, which is ideal for home bakers with limited space.

The choice between rimmed and rimless baking sheets depends on your specific baking needs. Rimmed sheets offer more versatility, allowing you to handle larger batches and more substantial bakes with ease, while rimless sheets provide simplicity and convenience for delicate and easy-to-transfer baked goods. For a home baker looking for versatility in their kitchen, rimmed sheets may be the better choice, while rimless sheets are ideal for those focused on delicate baking tasks. Understanding these benefits can help you choose the right baking sheet style for your culinary needs.

Nonstick Coating or Uncoated? A Guide for Home and Commercial Bakers

When choosing between nonstick-coated and uncoated cookie baking sheets, it’s important to understand their distinct advantages and how they cater to both home and commercial bakers. Each option offers unique benefits that can impact the ease of use, performance, and longevity of the sheet.

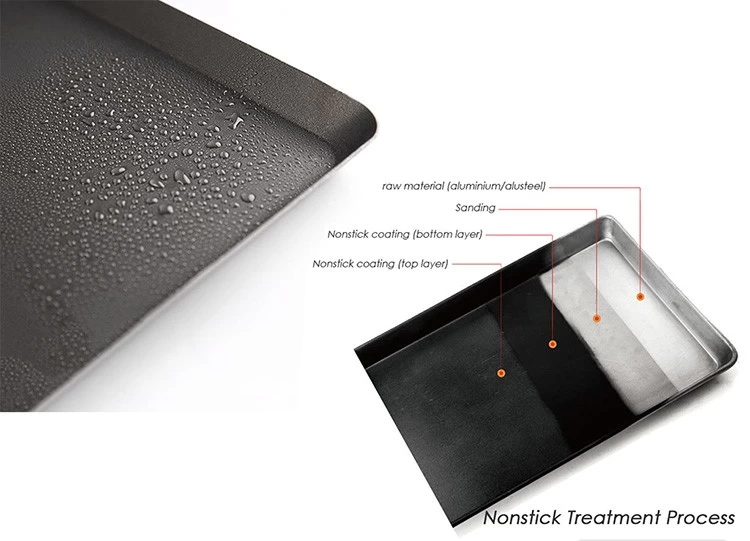

Nonstick-coated baking sheets are popular for their convenience, particularly for home bakers. The primary advantage of a nonstick coating is its ease of cleaning. Baked goods, especially sticky ones like sugar cookies or pastries, release effortlessly from the smooth, nonstick surface, reducing the need for excessive scrubbing. This makes cleanup a breeze, as food residue doesn’t stick to the surface. Additionally, nonstick sheets often have a more uniform baking experience, as they promote even browning and prevent edges from over-browning. The nonstick coating also helps to minimize the use of added fats or oils, making them a healthier choice for calorie-conscious bakers. However, it’s important to note that nonstick coatings can wear over time, especially with aggressive scrubbing or exposure to high heat, which can shorten the sheet’s lifespan.

Uncoated baking sheets, typically made from aluminum or stainless steel, offer a more durable and versatile option, particularly for commercial bakers. The main benefit of using uncoated sheets is their longevity and robustness. They are less prone to damage from scratches and scuffs compared to coated sheets, making them ideal for heavy-duty use. Uncoated sheets also allow for better caramelization of baked goods, which can enhance flavor, as they don’t prevent the natural Maillard reaction that adds depth to cookies and crusts. While uncoated sheets may require more effort to clean—sometimes necessitating soaking and a bit more elbow grease to remove baked-on residue—they tend to perform better over time with proper care. They are also heat resistant to a higher degree than coated sheets, making them suitable for more intense baking tasks without the risk of damage to the pan.

In terms of performance, uncoated sheets offer a more consistent and reliable baking experience, particularly for commercial environments where durability and long-term performance are crucial. They handle high temperatures better, making them suitable for tasks like baking sheet cakes or roasting vegetables, which can expose the pan to higher heat. On the other hand, nonstick sheets are easier to clean and maintain, which is a significant advantage for home bakers who may not have the same level of time or inclination for meticulous maintenance. The trade-off with nonstick coatings is slightly diminished longevity due to the potential for wear over time.

Ultimately, the choice between nonstick-coated and uncoated cookie baking sheets comes down to individual needs and priorities—ease of use and convenience versus durability and consistent performance. Both options have their merits, but understanding these differences will help home and commercial bakers make an informed decision based on their specific baking requirements.

Why Size and Shape Are Important

When it comes to baking, the size and shape of baking sheets play a crucial role in achieving optimal results. Understanding the standard sizes and choosing the right one for your needs can greatly impact the efficiency and quality of your baking.

The most common sizes for baking sheets are the half-sheet, quarter-sheet, and full-sheet sizes. A half-sheet measures 18 inches by 13 inches and is the most versatile size, fitting perfectly in most home ovens. It is ideal for baking a variety of goods, from cookies and brownies to sheet cakes and roasting vegetables. The quarter-sheet measures 9 inches by 13 inches and is more compact, making it perfect for smaller households or for those who only bake occasionally. This size is also great for items like individual-sized treats or when space is at a premium in home kitchens.

For commercial setups, the full-sheet measures 26 inches by 18 inches and is commonly used in professional kitchens due to its larger capacity. It is suitable for baking large quantities of goods or when you need to cook for many people at once. The full-sheet size requires industrial-sized ovens or custom racks to accommodate its dimensions, making it more practical for commercial bakeries.

When selecting the right size of baking sheet, it’s important to consider both the available space in your oven and the types of bakes you frequently do.

Home Ovens: In home kitchens, the half-sheet is typically the most versatile choice due to its ability to fit comfortably in most standard home ovens. It can handle large batches of cookies, sheet cakes, or roasted vegetables without taking up excessive space. For households with limited oven space, a quarter-sheet might be a better fit, offering the flexibility to bake small quantities without compromising on efficiency.

Commercial Setups: In a commercial setting, full-sheet pans are ideal due to the high volume of baked goods that need to be produced. These sheets can accommodate larger quantities of cookies, breads, and other baked goods, making them indispensable for high-output environments like restaurants and bakeries. However, the size also requires sufficient storage space and appropriate oven racks, which can be a limitation if the kitchen is not well-equipped.

The choice of size affects not only the efficiency of baking but also the quality of the results. A sheet that is too large may result in uneven baking due to inadequate heat distribution, while a sheet that is too small might restrict airflow and lead to overcrowding. Understanding the standard sizes and their applications can help home and commercial bakers select the appropriate size to suit their specific ovens, maximizing efficiency and ensuring optimal baking results.

Perforated Baking Sheets: Are They Worth It?

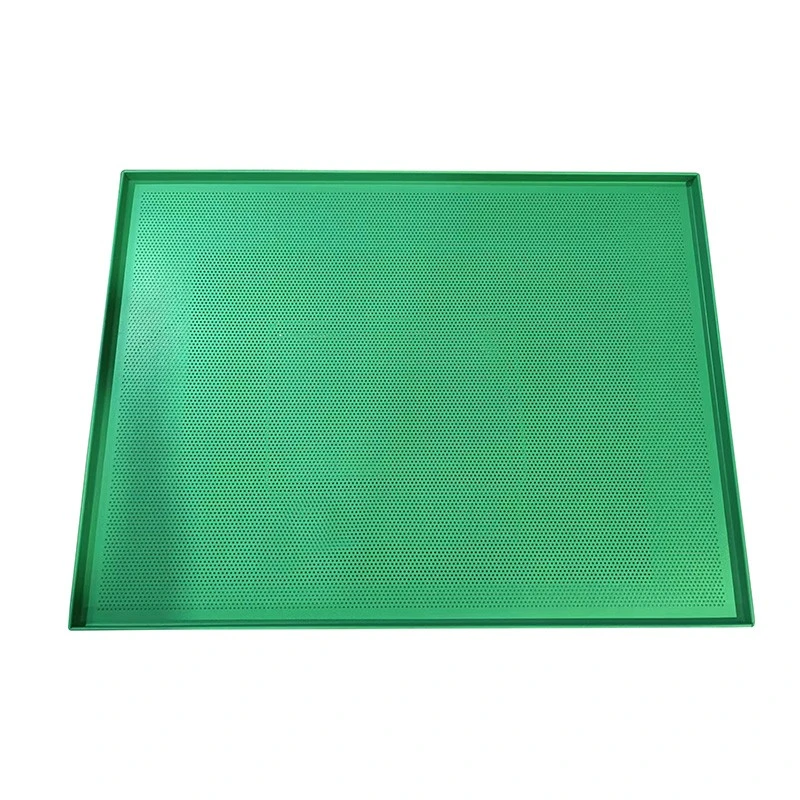

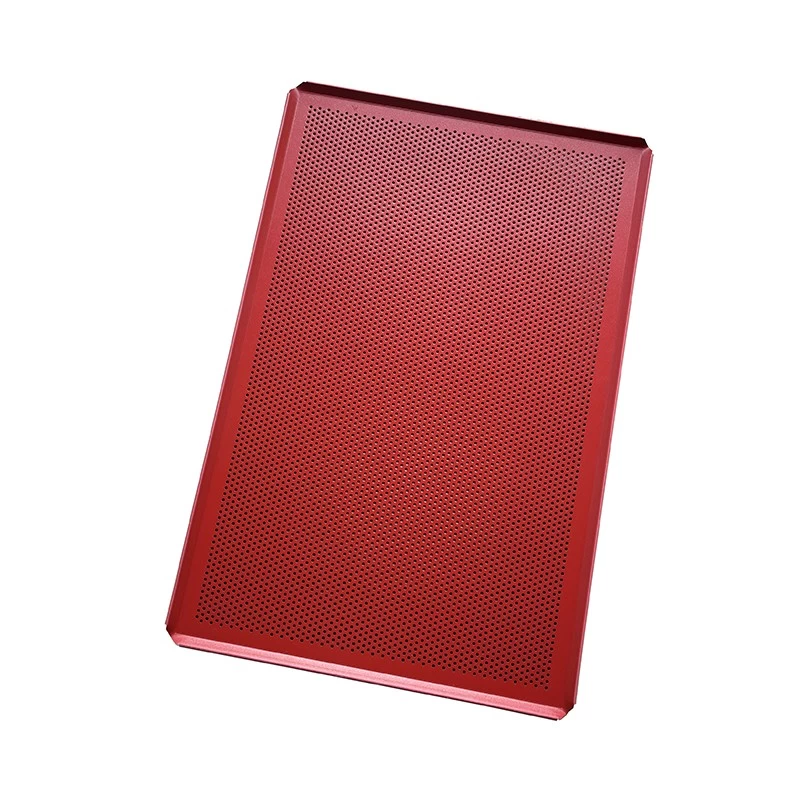

Perforated baking sheets, also known as air-flow or vented baking sheets, are gaining popularity for their ability to improve the quality of baked goods, particularly cookies. These sheets are designed with small holes or perforations throughout the surface, which can significantly impact how air circulates around the baking item and affect the final texture of baked goods.

How Perforated Sheets Work

Perforated baking sheets are constructed with small holes or slots evenly distributed across the sheet’s surface. These perforations allow for better airflow around the baked item, facilitating a more even distribution of heat and helping to dissipate moisture quickly. This improved airflow can result in a crisper bottom crust for baked goods like cookies, as it prevents the accumulation of steam that can make cookies soft and soggy. The perforations also help to prevent the formation of hot spots, ensuring that heat is evenly distributed across the baking surface, which is crucial for achieving uniform results.

Impact on Cookie Crispness

The impact of perforated baking sheets on cookie crispness is particularly noticeable. Traditional baking sheets can sometimes trap moisture, leading to cookies that are less crisp and more prone to becoming chewy. Perforated sheets, by allowing steam to escape, promote a crisper texture, which is ideal for recipes like shortbread or biscotti. The increased airflow ensures that the bottom of the cookie remains dry and crispy, while the top remains tender. This effect is especially beneficial for commercial bakers looking to produce consistent, high-quality cookies with a desirable crispness.

Advantages for Home and Commercial Use

For home bakers, the benefit of a perforated baking sheet lies in its ability to enhance the quality of baked goods without the need for added fats or excessive baking time. The even heat distribution and reduced baking time can result in perfectly browned, crispy cookies with minimal fuss. For commercial setups, these sheets are invaluable for high-volume baking, ensuring efficiency and consistent results across batches. The reduced risk of cookies sticking and the evenness of baking make perforated sheets a preferred choice for commercial bakers aiming for high-output, consistent quality.

Are They Worth It?

The decision to invest in perforated baking sheets comes down to the specific needs of the baker. For those who prioritize a crisp, golden bottom crust on cookies and other baked goods, perforated sheets are worth the investment. The improved airflow can make a noticeable difference in the texture and quality of baked items, making them particularly beneficial for home bakers looking to elevate their baking game or for commercial bakers aiming for efficiency and consistency. However, for bakers who are content with traditional baking sheets and do not mind the occasional soft-bottomed cookie, the investment in perforated sheets may not be necessary. Ultimately, the value of perforated baking sheets lies in their ability to enhance the baking process and improve the quality of the end product.

Maintenance Tips for Longevity

Maintaining your baking sheets properly is crucial for extending their lifespan and ensuring they perform well over time. Regular care and proper storage can prevent damage, maintain their nonstick properties (if coated), and keep them looking and working like new. Here are some practical tips for cleaning and storing baking sheets to maximize their longevity.

Cleaning Tips

- Hand Washing: For uncoated and nonstick baking sheets, hand washing is often the best method. Use a mild dish soap and warm water, along with a non-abrasive sponge or cloth. Avoid using steel wool or harsh scouring pads, as they can scratch the surface and damage any nonstick coating. Gently scrub away any residue, paying special attention to the corners and perforations of perforated sheets, which can trap food particles.

- Avoid Soaking: While soaking can help loosen stubborn baked-on food, it’s important not to soak nonstick baking sheets for too long, as it may damage the nonstick coating. Instead, try to remove food residues promptly after use by soaking for just a short period if needed, then gently scrub with a soft brush or sponge.

- Regular Maintenance: Regularly clean your baking sheets after each use to prevent buildup. Baking sheets that are used frequently can accumulate layers of residue that can be difficult to remove if left for a long time. Regular maintenance helps keep the surface free from food particles and oils that can degrade the coating or metal over time.

Storing Tips

- Stacking: Store baking sheets by stacking them vertically to save space and reduce the risk of scratching or damaging the surface. Place a sheet of parchment paper or a clean, thin cloth between each sheet to protect the surface from scratching when stacked. This is particularly important for nonstick and perforated sheets, which are more prone to damage from metal-on-metal contact.

- Avoid Heavy Objects on Top: When stacking baking sheets, avoid placing heavy items on top. The weight can distort or bend the sheets over time, especially with aluminum or aluminized steel sheets. This deformation can affect the baking results, making the sheet uneven.

- Proper Storage Location: Store baking sheets in a cool, dry place. Avoid storing them in humid environments, such as near a sink or dishwasher, which can lead to rusting or deterioration of metal surfaces. A dry pantry or kitchen cabinet is an ideal storage location.

- Nonstick Care: For nonstick baking sheets, consider placing them in a non-stick-safe storage bag or container to protect the coating from scratches and wear. Handle them with care during storage to prevent damage to the nonstick surface.

By following these maintenance tips, you can extend the life of your baking sheets, maintain their performance, and keep them looking good for years to come. Regular cleaning and careful storage are key to ensuring that your baking sheets remain a reliable and effective tool in your kitchen.

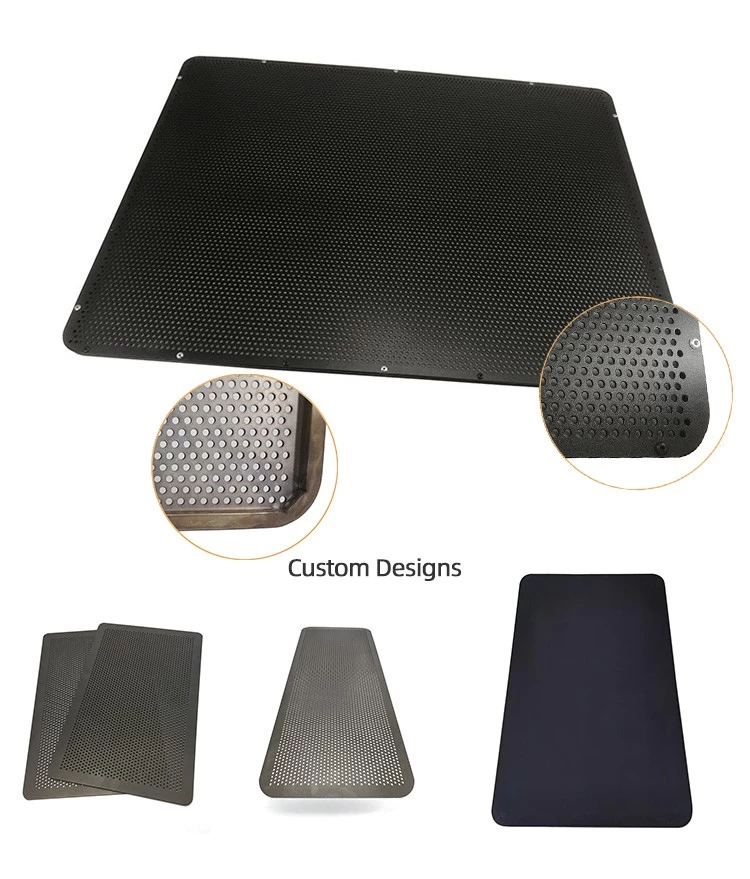

Custom Baking Sheets for Professional Bakers

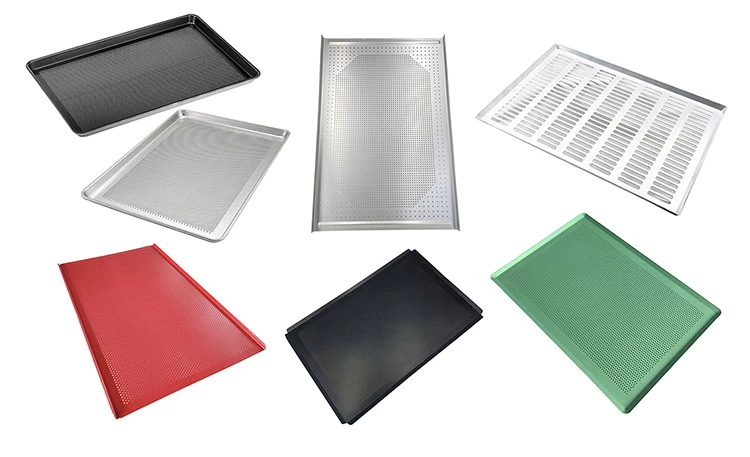

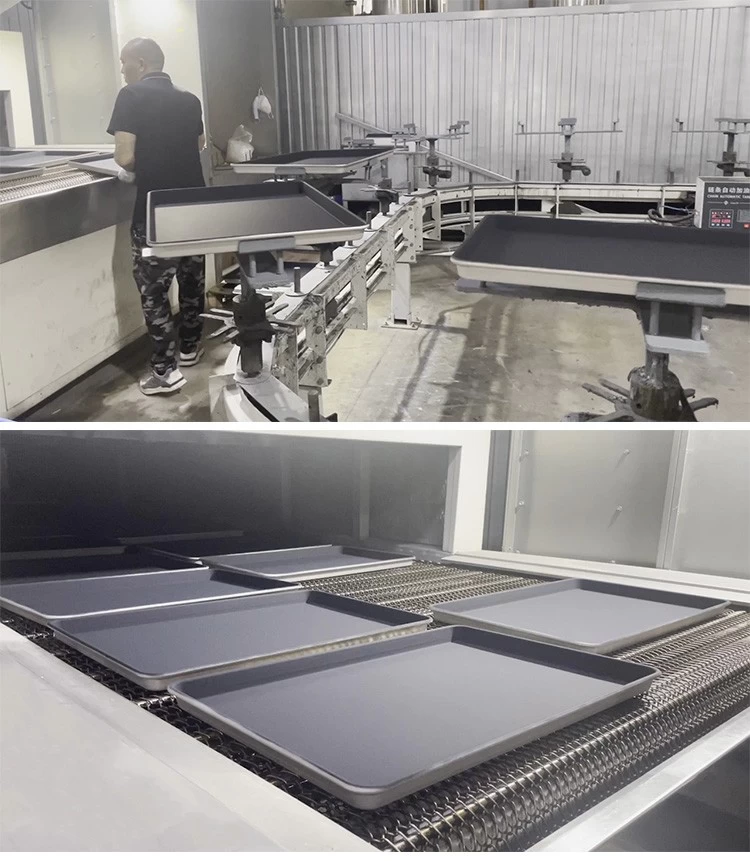

Custom baking sheets are increasingly in demand among professional bakers who require specialized tools to meet specific baking needs in commercial kitchens. Standard baking sheets can be versatile, but custom sheets provide the precision and tailored features that are essential for achieving optimal results in professional settings. Tsingbuy, as a leading aluminum baking sheet manufacturer in China, plays a crucial role in meeting these needs by offering both standard baking sheets and the ability to produce custom baking sheets that cater to the unique requirements of commercial bakeries.

Tsingbuy's Role in Standard and Custom Baking Sheets

Tsingbuy is known for its high-quality baking sheets that are widely used in both home and commercial kitchens. Our range includes standard options like half-sheet, quarter-sheet, and full-sheet sizes, which are designed to fit in most ovens and meet the typical needs of bakers. These standard baking sheets are constructed from durable materials such as aluminized steel, stainless steel, and aluminum, ensuring even heat distribution, long-lasting performance, and resistance to warping. They are perfect for tasks like baking cookies, roasting meats, and preparing sheet cakes due to their versatility and robustness.

However, Tsingbuy also excels in producing custom baking sheets tailored to the specific requirements of professional bakers. Our custom options allow commercial kitchens to optimize their baking processes and achieve consistent results. This capability is crucial for specialized applications such as baking high quantities of bread, managing multiple baking temperatures, or accommodating oversized items like pizza or sheet cakes. Custom baking sheets can be designed with features like specialized perforations for improved airflow, customized sizes to fit unique oven dimensions, or specific materials to enhance heat conductivity or durability. This flexibility enables bakers to push the boundaries of what’s possible in their kitchens, ultimately leading to better product quality and efficiency.

Specialized Needs in Commercial Bakeries

In commercial bakeries, where precision and consistency are critical, having the right tools is essential. Custom baking sheets from Tsingbuy allow professional bakers to create an optimized environment for baking large volumes of goods efficiently. For example, custom sizes and shapes can fit specific oven racks or align with specialized equipment, reducing the need for manual adjustments during production. Additionally, custom perforated sheets can help achieve even browning and crispness, reducing baking times and improving the texture of cookies and breads.

Tsingbuy’s ability to produce custom baking sheets is a game-changer for commercial bakeries that need equipment tailored to their unique processes. Whether it’s adjusting the gauge of the metal for better heat retention, incorporating additional materials like silicone for nonstick properties, or creating unique shapes for specific baking needs, Tsingbuy non stick baking sheet supplier in China ensures that each custom sheet meets the highest standards of quality and functionality. This level of customization allows professional bakers to enhance their baking performance, reduce waste, and streamline their production processes, ultimately leading to greater success in the competitive baking industry.